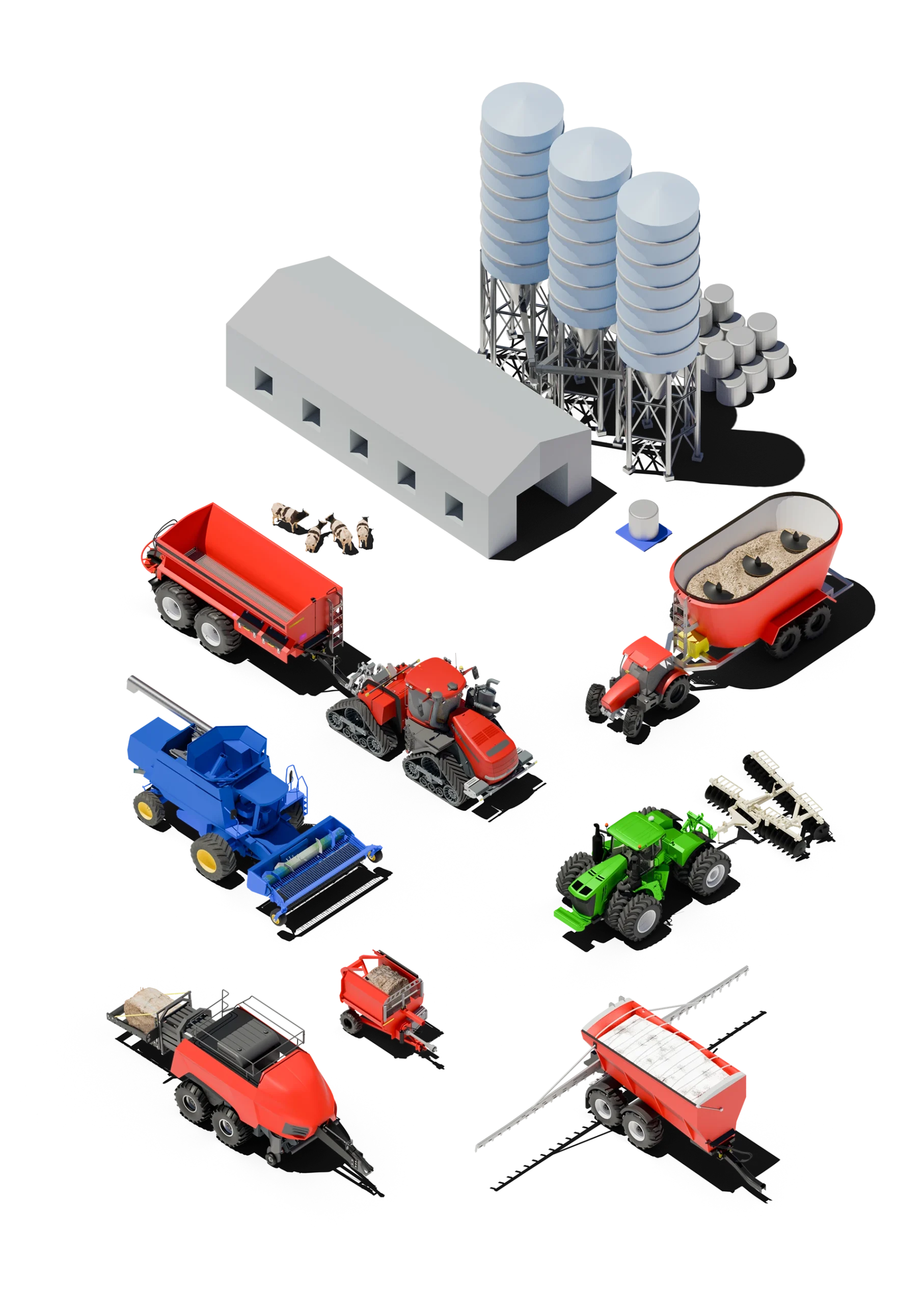

Agricultural Machinery

Enabling Automation and Precision Agriculture

Weighing and force sensors are essential to modern mobile farm equipment, enabling smarter, more efficient operation in the field. From controlling seeding depth to managing feed distribution or monitoring load weight, accurate measurement directly impacts performance, safety, and productivity.

ANYLOAD provides rugged, high-performance load cells and force sensors tailored for mobile ag machinery operating in rough terrain and demanding environments. Our sensors integrate easily into OEM systems, with support for CAN bus and other fieldbus protocols used in precision farming and automated control systems.

Applications Include:

- Combine Harvesters → Monitor Grain & Flow Yield Real-time grain flow and bin weight monitoring

- Feed Mixers & Blenders → Ensure Accurate Feed Weighing Accurate load measurement during mixing and transport

- Tillage & Seeding Equipment → Control Depth & Draft Force Depth calibration, draft force sensing, and seed/fertilizer metering

- Fertilizer Spreaders & Applicators → Optimize Application Weight-based dosing, hitch load feedback, variable rate application

- Hay & Forage Equipment → Load Management & Consistency Monitoring bale weight, forage load, and trailer fill levels

- Tractors, Loaders & Implements → Enhanced Control Arm force sensing, hitch load feedback, and safety

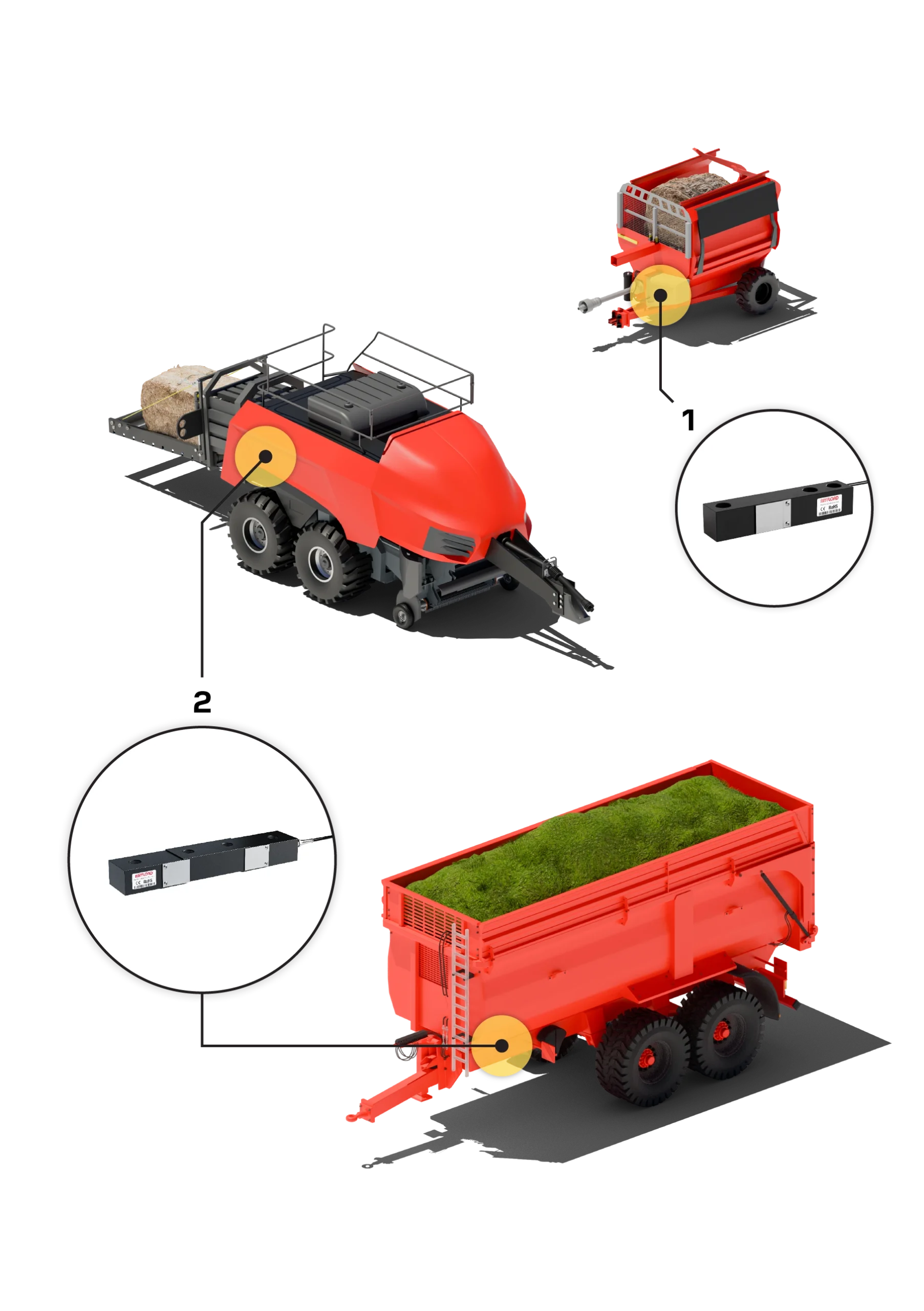

Hay & Forage

Precision load monitoring in hay balers, accumulators, and forage harvesters is critical for automated handling, load optimization, and machine longevity. ANYLOAD sensors are designed to withstand extreme vibration, impact, and shifting loads from rough terrain and continuous motion to deliver reliable weight data.

Challenges & Solutions

- Harsh Operating Conditions: Equipment faces constant jolts, dust, moisture, and temperature swings. ANYLOAD load cells feature hermetic sealing, reinforced housings, and IP-rated protection for maximum reliability.

- Dynamic Load Variability: Integrated weight sensors must compensate for uneven ground forces and shifting loads. Our solutions include data filtering, multi-point calibration, shock resistance, and rapid sampling times to deliver accurate data.

- Bale & Trailer Load Monitoring: For silage wagons, forage trailers, and bale accumulators, load cells track real-time weight to prevent overloading, support on-the-go logistics, and optimize transport and offloading operations.

To Learn More:

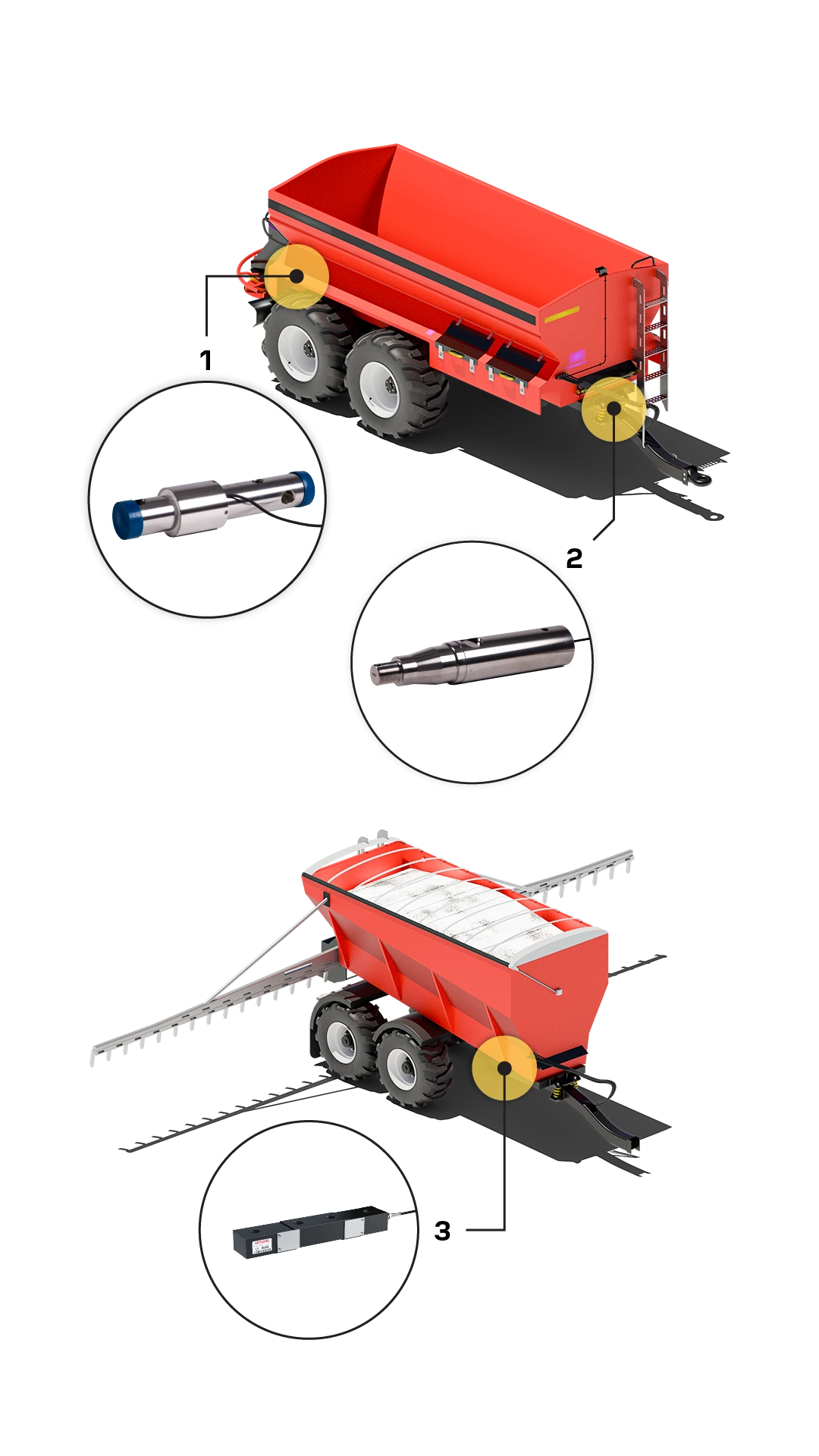

Spreaders & Applicators

Accurate weight measurement in fertilizer spreaders and pesticide applicators is crucial for precise application rates, inventory tracking, and field efficiency. ANYLOAD supplies rugged, high-capacity load cells engineered to handle continuous vibrations, corrosive chemicals, and high-impact loads from hopper agitation and rough terrain. As a trusted supplier to ag OEMs, our solutions integrate with variable-rate application (VRA) systems and other precision ag technology, improving yield optimization and input efficiency.

Challenges & Solutions

- Chemical Exposure & Corrosion: Fertilizers, lime, manure, and other granular materials are hygroscopic and highly corrosive. ANYLOAD load cells use a range of solutions including EPD coating, hermetic sealing, and chemical-resistant cable and connectors for long-term durability.

- Heavy Dynamic Loads: Spreaders experience constant jolting and load cycling as material shifts in the hopper. ANYLOAD load cells are fatigue-rated, designed and tested for continuous duty in demanding field conditions.

- Hitch Sensing & Drive Control: Spindle and tongue load cells provide real-time force feedback for hitch load balancing, draft force sensing, and drive system optimization, improving stability, traction, and power efficiency in variable field conditions.

- Boom & Tank Load Monitoring: In liquid applicators and sprayers, load cells can track tank levels and monitor boom load distribution without direct sensor exposure to the liquid contents.

To Learn More:

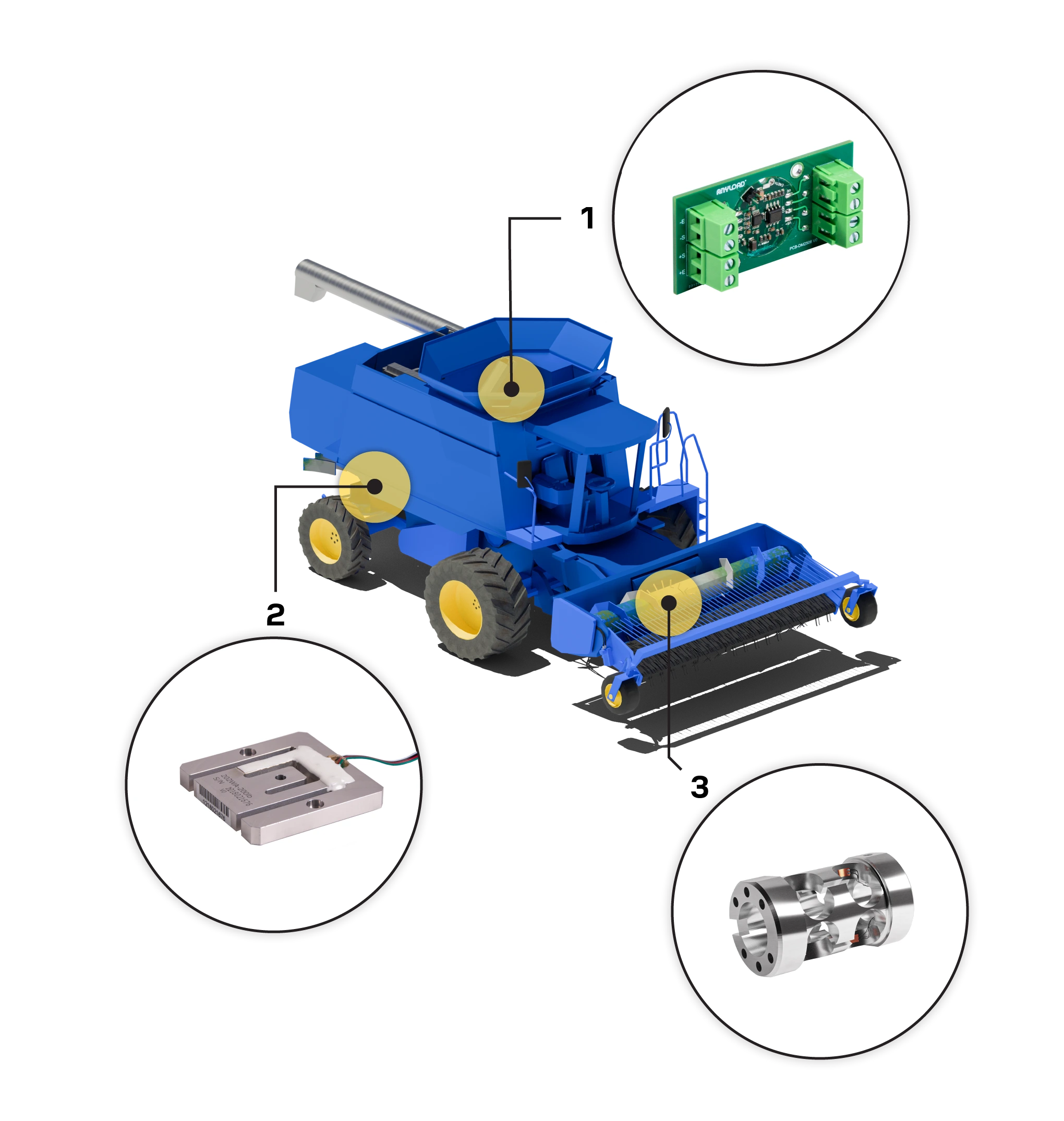

Combine Harvesters

Load cells play a critical role in harvesters, combines, and other mobile grain handling equipment, enabling precision agriculture through yield monitoring, load distribution, and efficient grain transfer.

Challenges & Solutions

- Yield Monitoring: Integrated load cells in elevator-mounted grain flow systems and hopper scales provide real-time weight measurements to track harvest output and improve yield mapping.

- Grain Tank & Auger Load Sensing: Load cells measure bin fill levels, preventing overloading, optimizing unloading rates, and ensuring smooth grain handling.

- Data Integration: ANYLOAD sensors support digital output protocols such as CAN bus and other fieldbus systems, enabling seamless integration into combine harvester control networks for real-time data acquisition and precision monitoring.

To Learn More:

Feed Mixers & Blenders

In livestock operations, accurate feed mixing and ration control are critical to animal health, productivity, and operational efficiency. ANYLOAD provides robust, high-performance load cells specifically engineered for TMR (total mixed ration) mixers, stationary and mobile blenders, and bulk feed handling systems.

Challenges & Solutions

- Dynamic Loading Forces: Feed mixers experience constant agitation, shifting loads, and mechanical stress. ANYLOAD’s fatigue-rated load cells handle maintain accuracy through continuous mixing cycles and high torque conditions.

- Corrosion Resistance: Moisture, salts, and acids in feed ingredients can degrade weighing components. ANYLOAD’s specially sealed and coated load cells are corrosion-resistant and built to withstand harsh agricultural environments.

- Mobile Operation Stress: ANYLOAD load cells maintain accurate weight measurement under continuous vibration, shock, and temperature extremes typical of truck- and trailer-mounted feed mixers in the field.

View Products:

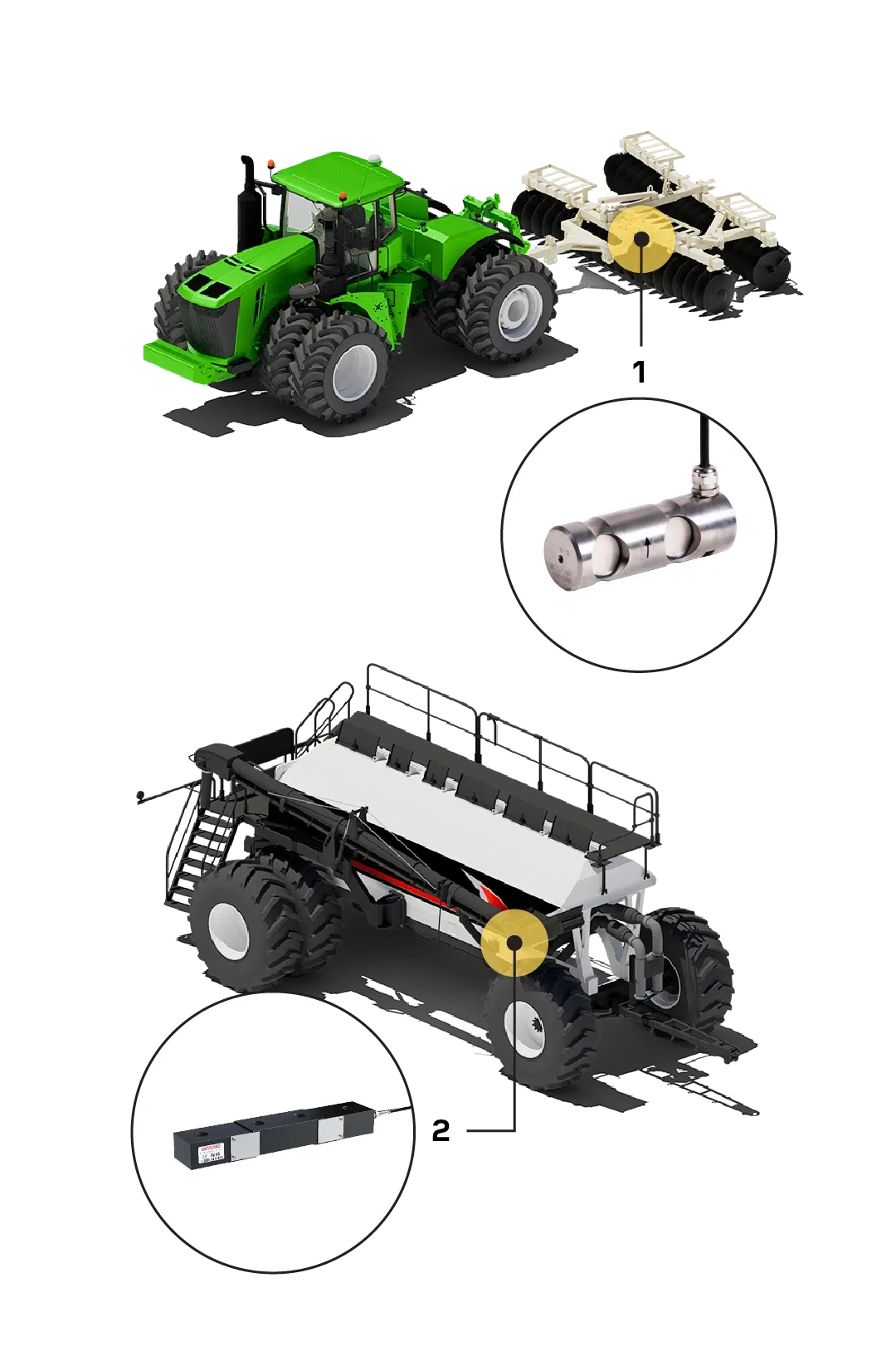

Tillage & Seeding

Load cells and torque sensors play a vital role in precision tillage and seeding, enabling accurate depth control, consistent soil engagement, and optimized seed placement across variable terrain. ANYLOAD integrates precision sensors into disc harrows, air drills, strip-till systems, and air carts, supporting automation and real-time feedback in advanced planting equipment.

Challenges & Solutions

- Non-Disruptive Integration: Force sensors must be compact and non-intrusive, fitting in-line into hydraulic arms, depth control linkages, or torque arms without affecting implement structure or travel.

- Air Cart Weight Monitoring: Load cells available with analog or CAN bus outputs mounted under air cart bins monitor application rates and prevent underfills or overloading as part of machine control systems and variable-rate applications.

View Products:

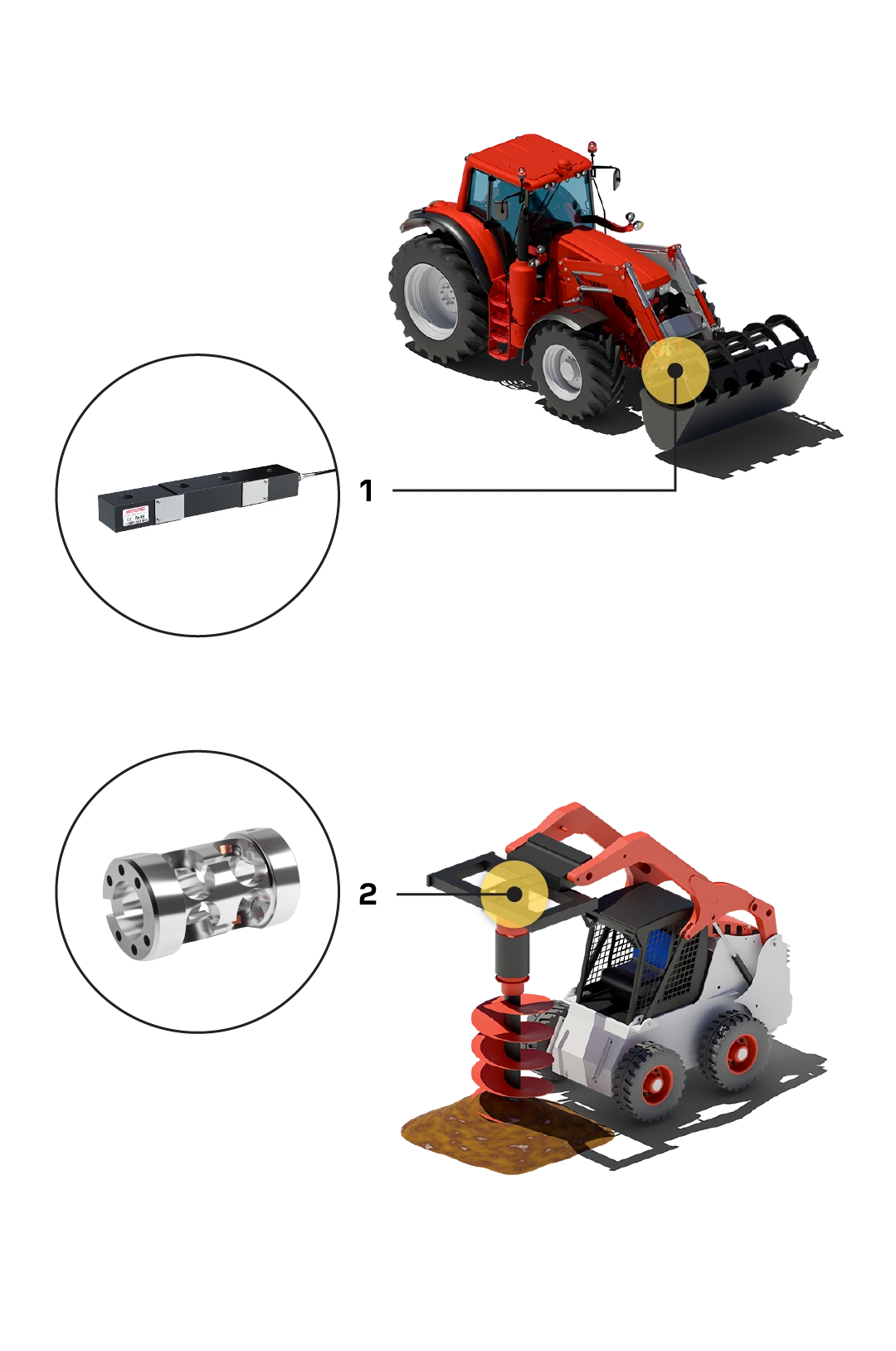

Tractors & Attachments

Modern tractors are multifunctional workhorses used for hauling, lifting, and operating a wide range of implements. ANYLOAD provides load cells and force sensors that enhance loader performance, implement control, and operational safety, supporting more automated, precise, and responsive field operations.

Challenges & Solutions

- Loader & Hitch Load Sensing: ANYLOAD sensors on loader arms, hitches, and tilt cylinders provide real-time force data for overload prevention, bucket control, and traction optimization.

- Implement & Draft Force Monitoring: Integrated sensors enable drawbar load tracking, tongue weight balancing, and automated depth control for towed and PTO-driven implements. ANYLOAD offers customizable force pins and load sensing assemblies, supporting modern precision agriculture demands with capacities suited for heavy field loads and seamless integration with OEM control systems.

View Products: