Weighing Systems Troubleshooting

Last Updated On March 15 • 10 min read

Introduction to Troubleshooting Weighing Systems

Troubleshooting weighing systems is a critical skill for maintaining the accuracy, reliability, and safety of your equipment. Whether you’re dealing with industrial scales, commercial weighing devices, or precision laboratory balances, understanding the basics of how these systems work and how to identify common issues is essential.

1. Getting Started

Before tackling troubleshooting, it’s important to have a grasp of several fundamental concepts:

- Basic Circuit Theory: Understanding how electrical circuits function is crucial since weighing systems generally rely on electronic components for operation.

- Wheatstone Bridge Circuits: Many weighing systems, particularly those involving load cells, utilize Wheatstone bridge circuits. Familiarity with how these circuits work and how they’re used in load cells will greatly aid in troubleshooting.

- Load Cell Fundamentals: Knowing how load cells convert force into electrical signals is key, as they are the heart of most weighing systems.

- Using a Multimeter: A multimeter is an invaluable tool in diagnosing electrical issues. Proficiency in measuring voltage, resistance, and continuity is necessary for effective troubleshooting.

2. Safety & Precautions

Electrical Safety

- Power Down: Before inspecting or servicing any part of the weighing system, always ensure it is completely powered down and isolated from the power source to prevent electric shock.

- Use Insulated Tools: Employ insulated tools and wear appropriate personal protective equipment (PPE), such as gloves and safety glasses, to safeguard against accidental electrical contact.

- Verify with a Multimeter: Before touching any components, use a multimeter to confirm there’s no residual voltage in the system.

Mechanical Safety

- Beware of Heavy Components: Many weighing systems contain components that are extremely heavy. Use proper lifting techniques and equipment when handling these parts to avoid injury.

- Secure the Area: Ensure the troubleshooting area is secure and clearly marked to prevent unauthorized access or accidental disturbances.

Environmental Awareness

- Stay Alert: Industrial environments can be unpredictable. Maintain awareness of your surroundings to avoid accidents, especially moving machinery or vehicles.

- Wear Proper PPE: Weighing systems are frequently located in hazardous environments. Please take care to ensure that anyone working on these systems are wearing the appropriate personal protective equipment for the worksite.

Handling Load Cells

- Cable Care: Never handle a load cell by its cable. Pulling, lifting, or yanking the cable can damage the internal wiring and connectors, compromising the load cell’s functionality. If a load cell needs to be disconnected, do so carefully at the connector or terminal, avoiding any cutting of the cable. Cutting a load cell cable not only risks damaging the system but also voids most manufacturers’ warranties, as it eliminates the possibility of determining if the issue originated from the cable itself.

- Avoid Impact Damage: Dropping or striking a load cell can cause irreparable harm to its internal components, leading to measurement inaccuracies or complete failure. Handle load cells with care, ensuring they are securely stored and transported in appropriate containers when not mounted.

ℹ️ Important Note:

If you notice that your junction box or indicator is secured with a wire seal or a tamper sticker, DO NOT attempt to open or service it on your own. Such seals often signify that the system is designated for legal-for-trade purposes, meaning it is certified for commercial transactions based on weight.

Tampering with or breaking these seals without authorization may violate legal regulations governing trade and commerce and would require recertification by an accredited technician or official inspector. In such cases, contact a certified professional.

3. Consult a Professional

While basic troubleshooting can be performed by those familiar with the system, complex or persistent issues should be addressed by professionals. Incorrect diagnostics or repairs can lead not only to further system damage but also to safety hazards. If you’re unsure or if the problem extends beyond basic fixes, it’s wise to seek expert help.

We strongly recommend consulting a professional for on-site assistance. Our global network of dealers is equipped to provide the support you need, ensuring your weighing systems operate smoothly and safely. For expert help in your area, visit our Find-a-Dealer page.

4. Root Cause Diagnosis

- Physical Inspection: Check the scale platform and foundation for signs of physical damage, wear, or deformation. Issues like bent frames, uneven surfaces, or obstructed movement can lead to inaccurate readings.

- Stability Check: Ensure the scale is level and stable. An unlevel scale can cause significant inaccuracies in measurements.

- Load Path: Verify that the load is being correctly transferred to the load cells. Any interference or misalignment in the load path can result in measurement errors.

- Clear Debris: Build-up of debris, including dirt, dust, snow, etc., underneath scale platforms can eventually interfere with the loading of the scale. Make sure that the scale systems are not being mechanically interfered with by regularly clearing debris.

- Display Check: Look for any irregularities on the scale’s display, such as flickering, incomplete digits, or unresponsiveness, which may indicate an instrumentation issue.

- Power Supply: Confirm that the instrumentation is receiving a stable power supply and check for any loose or damaged connections.

- Keypad Check: Ensure that the instrumentation touch interface is fully functioning and that any inputs to its keypad, buttons, and other switches properly register into the system.

- Visual Inspection: Examine each load cell for physical damage, such as cracks, corrosion, or signs of overload. Even slight damage can affect performance.

- Electrical Checks: Use a multimeter to perform basic electrical checks on each load cell, including continuity, resistance, and, if applicable, insulation resistance

- Output Signal: Measure the output signal of each load cell under a known load to verify that it falls within the expected range. Deviations from expected values can indicate a faulty load cell.

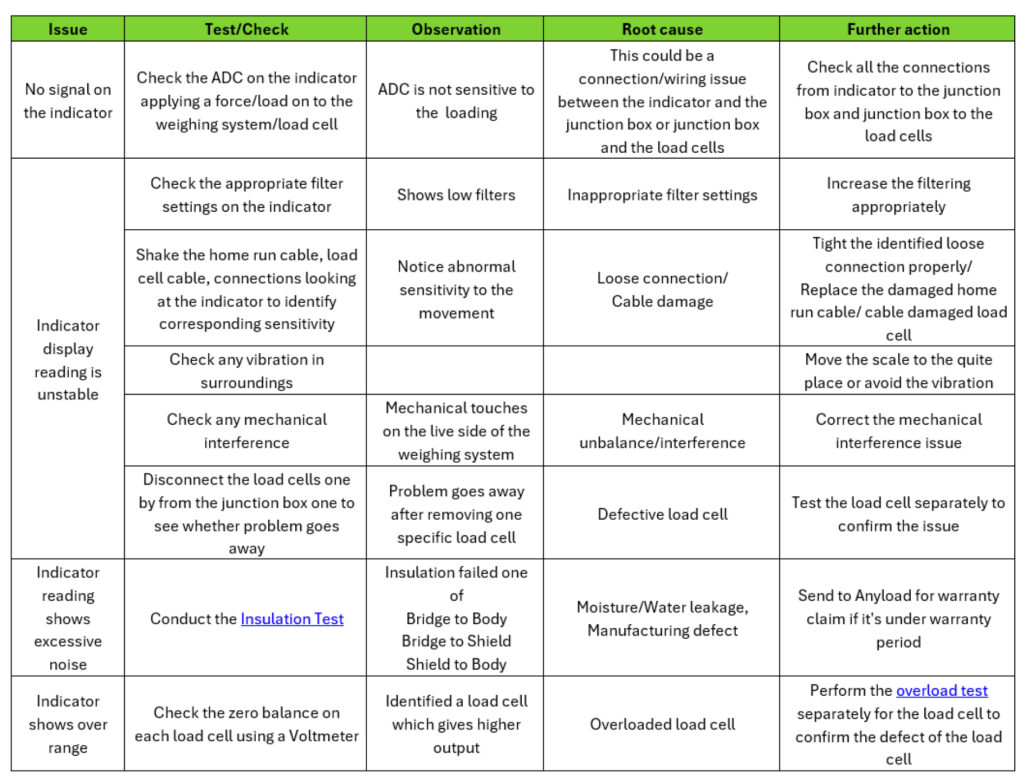

5. Common Issues of Weighing Systems

6. In-Depth Troubleshooting

Once the source of the problem is isolated to a specific component of a weighing system, follow the guidelines for troubleshooting these specific components.