What is a Load Cell?

Last Updated On • 10 min read

A load cell is a precision measurement sensor—a force transducer that converts a mechanical force into an electrical signal that can be measured, conditioned, and analyzed. When a force (e.g., tension, compression, shear, torque, etc.) is applied, a load cell converts this force into an electrical signal output that changes proportionally to the force applied.

Load cell sensors enable consistent, reliable measurements of force and are widely used in a large variety of weighing and other force measurement applications. This includes the weighing of products in trade and logistics, ensuring safety, enabling automation, and calibrating devices. They are used in many industries such as packaging, automotive, chemical processing, agriculture, construction, medical, pharmaceutical, test & measurement, robotics, and much more.

There are many types of load cells that converts force differently into some form of an output, including pneumatic/hydraulic, piezoelectric, vibrating wire, and strain gauge. Load cells using strain gauge technology are the most common, found in the majority of industrial and commercial applications. Strain gauge-based load cells are favored for its versatility, durability, and relative cost-effectiveness.

As the “nerve” of most electronic scales and weighing systems, load cells enable commerce of all physical goods and maximize efficiency by providing a standardized and consistent weight sensor at the heart of scales. In industrial applications, load cells are not just components for weighing scales but are critical as force measurement sensors for a vast range of applications ranging from a few grams to hundreds of tons, including in automated processes, quality assurance, equipment calibration, safety monitoring, and much more.

1. Strain Gauge Load Cells

1.1 What is a Strain Gauge Load Cell?

Strain gauge load cells are the most common form of load cells in industrial and commercial applications as it delivers a high level of accuracy while being able to withstand harsh conditions. Its simple yet effective design facilitates integration into a broad range of equipment, from high-precision laboratory scales to heavy-duty industrial weighing systems.

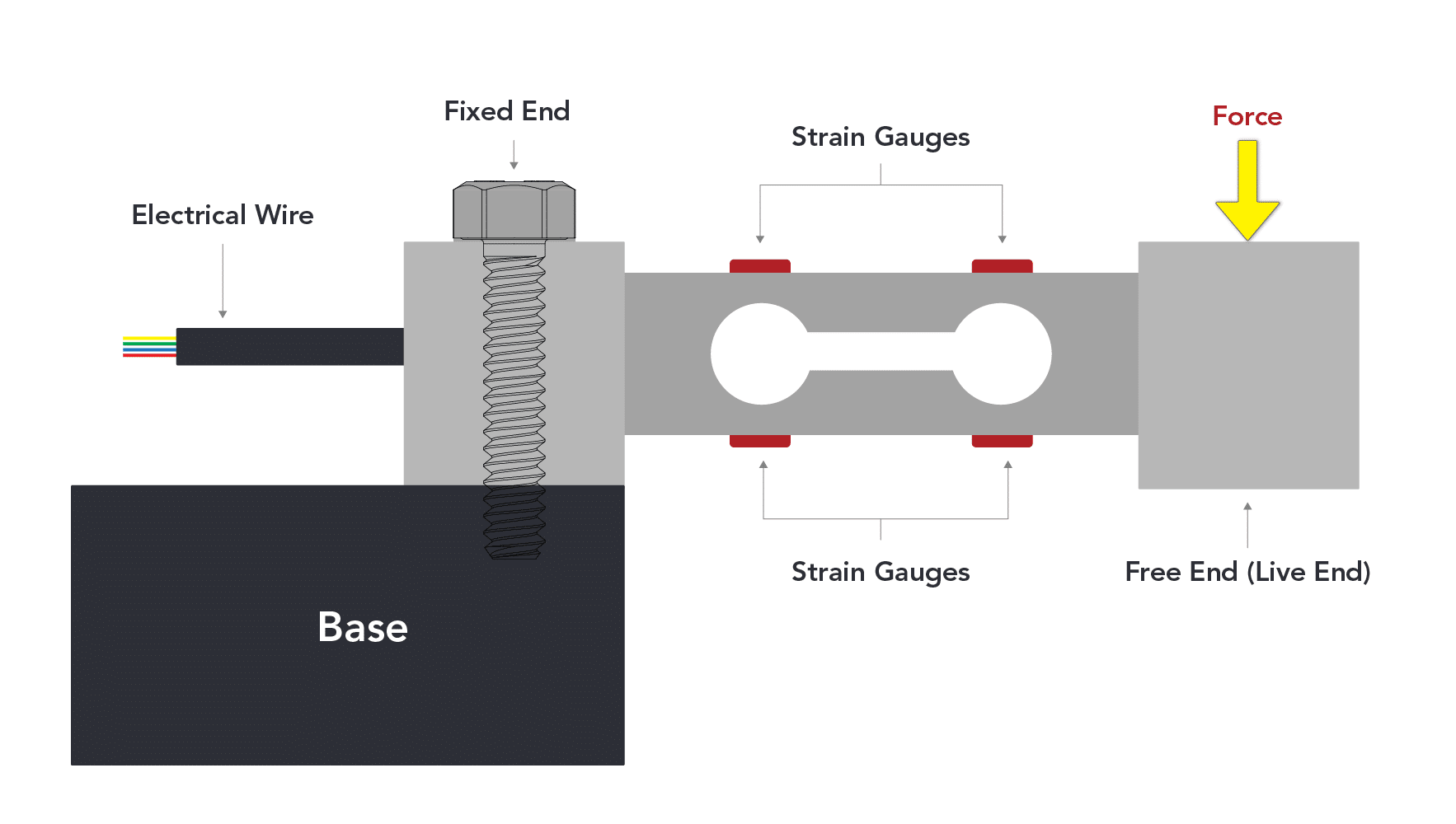

Strain gauge load cells convert the deformation of a metal body into measurements in the form of proportional changes in electrical resistance.

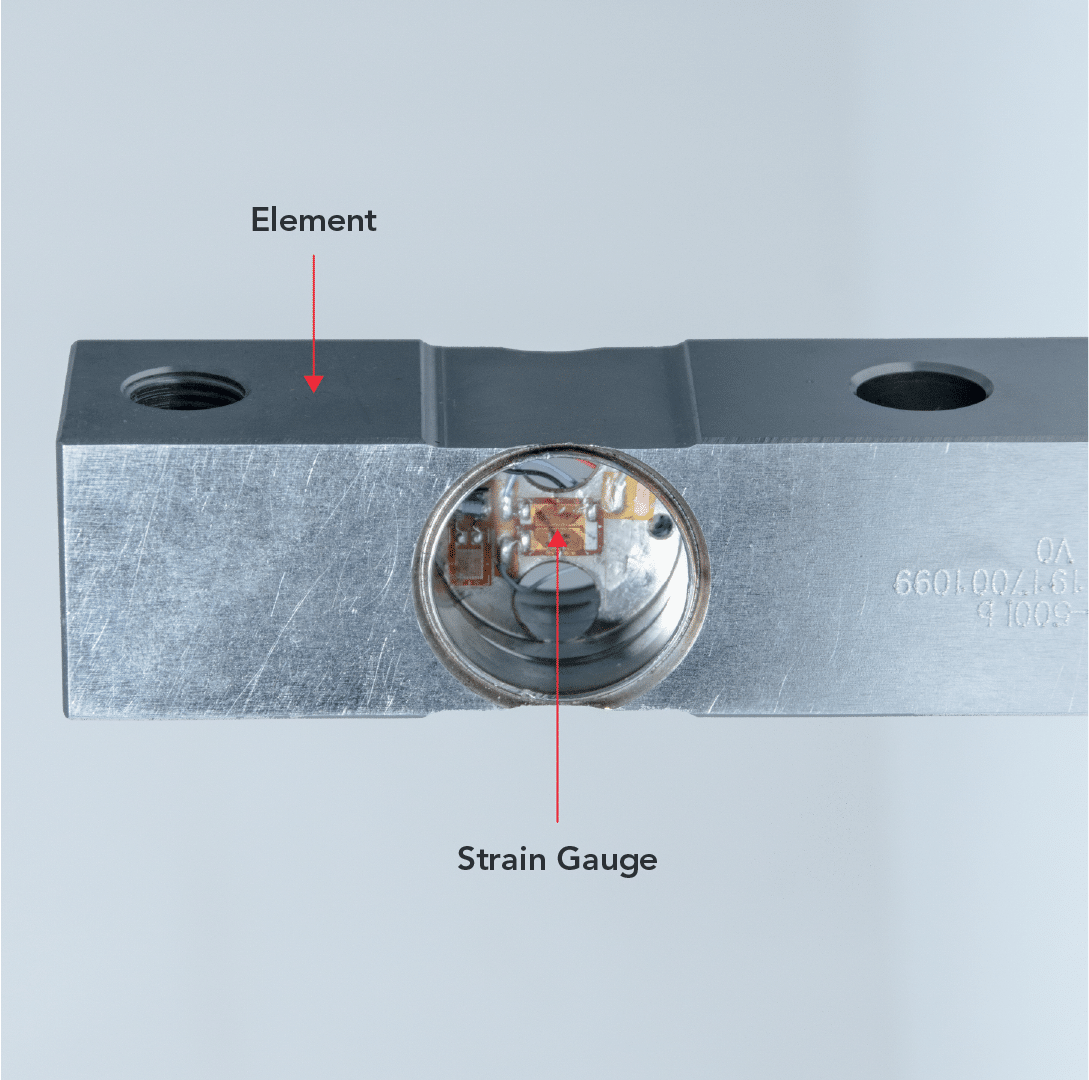

A strain gauge load cell is based on 2 critical components:

- Element: A machined piece of metal that deforms consistently in proportion to the force applied.

- Strain gauges: Type of variable resistor that changes in resistance output in proportion to the deformation of the metal.

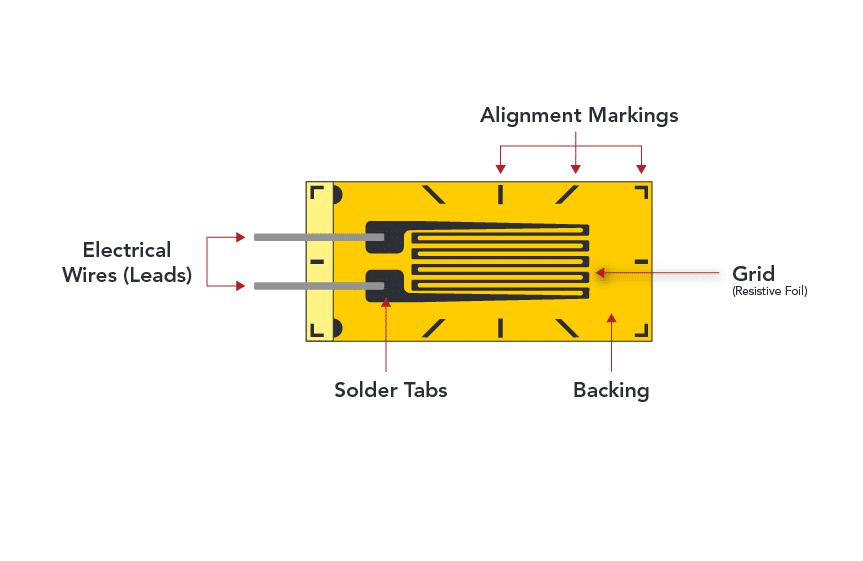

1.2 Strain Gauge

Strain gauges, as variable resistors, respond to physical deformation by altering their electrical resistance, a change that’s precisely measured when they’re integrated into a Wheatstone bridge circuit. This setup, involving four interconnected resistive arms with at least one being a strain gauge, not only allows for highly accurate resistance measurements but also compensates for temperature-induced errors and enhances sensitivity to minute strain-induced resistance variations. The result is a stable and repeatable output signal that is crucial for high-precision force and weight measurements.

1.3 Load Cell Element

A sensing element is a precisely machined piece of metal (typically made from high grade alloy steel, stainless steel, or aluminum) to which strain gauges are bonded. The element not only acts as a durable enclosure, safeguarding the delicate gauges, but also possesses carefully calibrated properties that allow it to deform in a controlled manner.

The element can come in a variety of shapes and sizes, allowing for strain gauge load cells to be easily integrated into a wide range of applications big and small.

Learn more about common load cell shapes.

2. Hydraulic Load Cells

2.1 What are Hydraulic Load Cells?

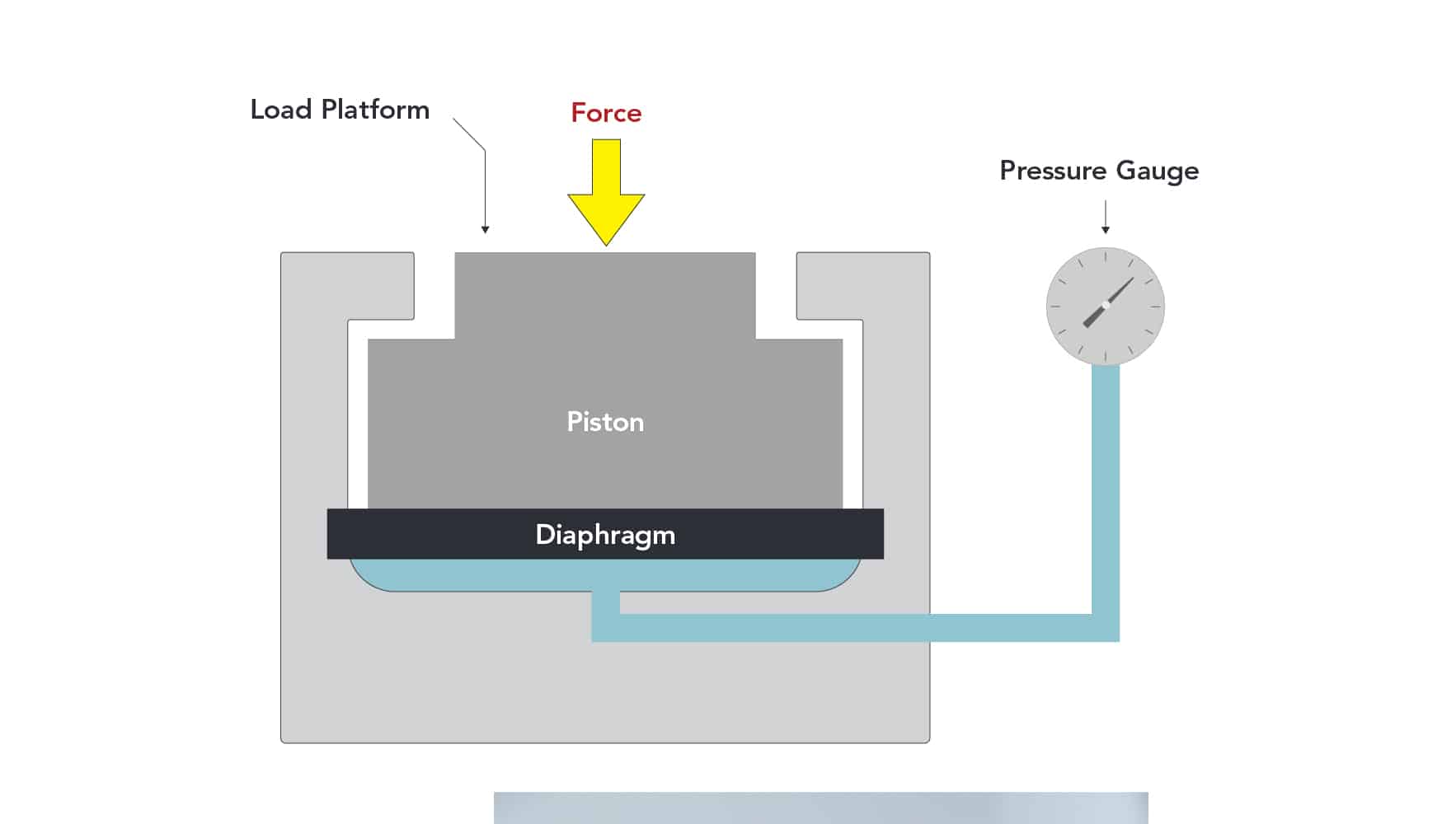

Hydraulic load cells contain a fluid-filled chamber and a piston. When a force is applied to the piston, it exerts pressure on the hydraulic fluid, which is then measured by a pressure gauge or transducer to indicate the force.

The construction of hydraulic load cells makes them inherently robust and suitable for high-capacity weighing, as they can withstand harsh environments and heavy loads. They are also not affected by fluctuations in electrical fields.

However, hydraulic load cells have certain limitations. They can be less responsive than electronic load cells, making them unsuitable for dynamic measurement where rapid changes occur. The viscosity of the hydraulic fluid can also vary with temperature, potentially affecting measurement accuracy.

Additionally, hydraulic systems require strict sealing to prevent leaks, which can complicate maintenance. The complexity and size of hydraulic load cells might also limit their application in spaces where compactness is required. Despite these drawbacks, their durability and precision in steady-state force measurement make them a valuable tool for certain industrial applications.

3. Pneumatic Load Cells

3.1 What are Pneumatic Load Cells?

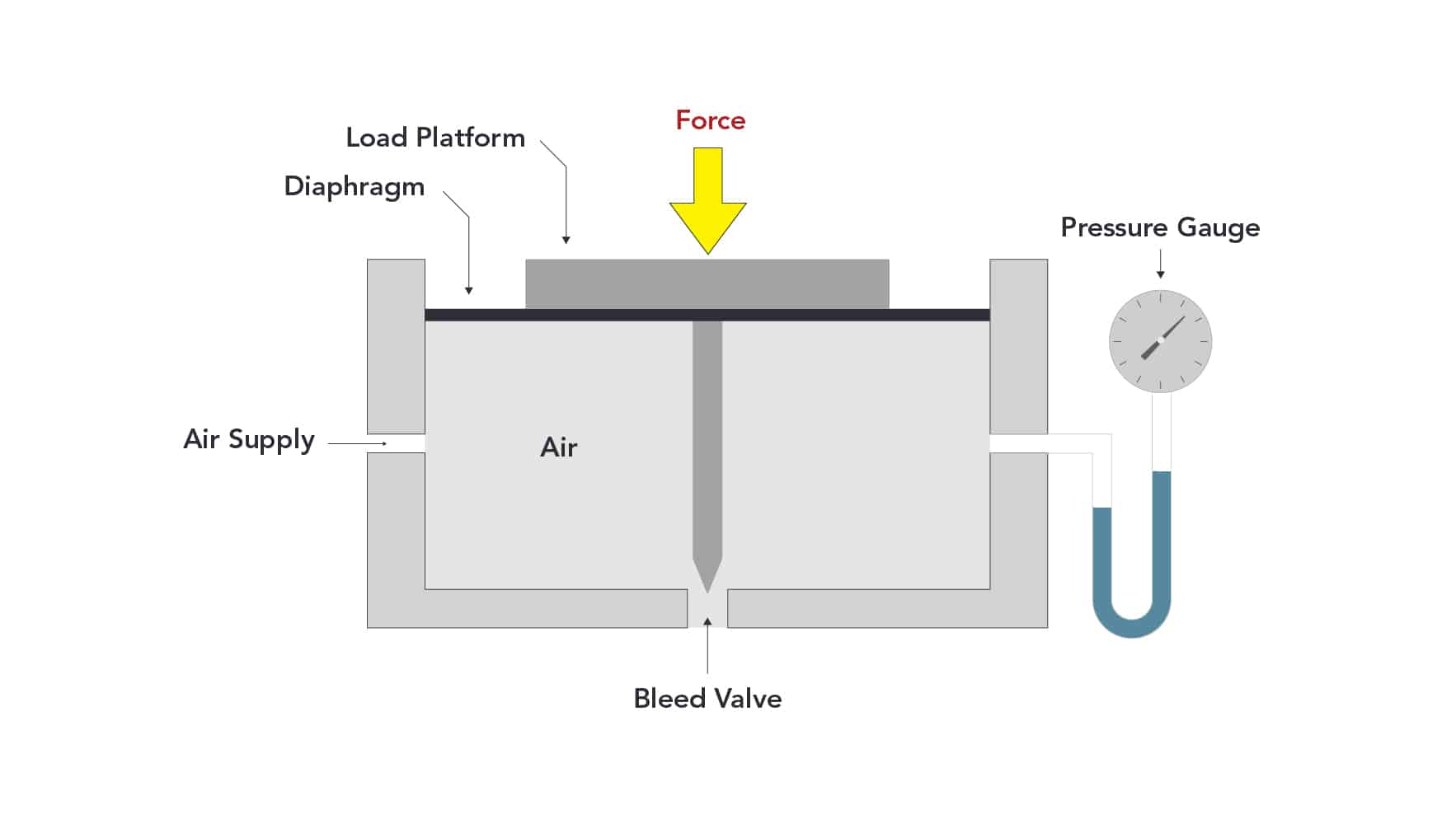

Pneumatic load cells operate by using air pressure to measure force. These cells harness the principles of fluid dynamics, where the mechanical force applied to a diaphragm is translated into changes in air pressure which is then measured.

When a load is applied, it causes a deformation in a diaphragm within the pneumatic load cell. This deformation changes the volume inside the cell, which in turn affects the air pressure. The pressure is then stabilized to a set point by adding or releasing air. The amount of air pressure needed to achieve this balance is indicative of the force applied and is measured by a pressure sensor.

While pneumatic load cells are safer for use in volatile environments due to their lack of electrical components, they come with several drawbacks. Their response times can be slower than electronic load cells, and the accuracy can be affected by changes in ambient air pressure and temperature. They also tend to have a lower resolution, making them less suitable for applications where fine measurements are crucial.

4. Piezoelectric Load Cells

4.1 What are Piezoelectric Load Cells?

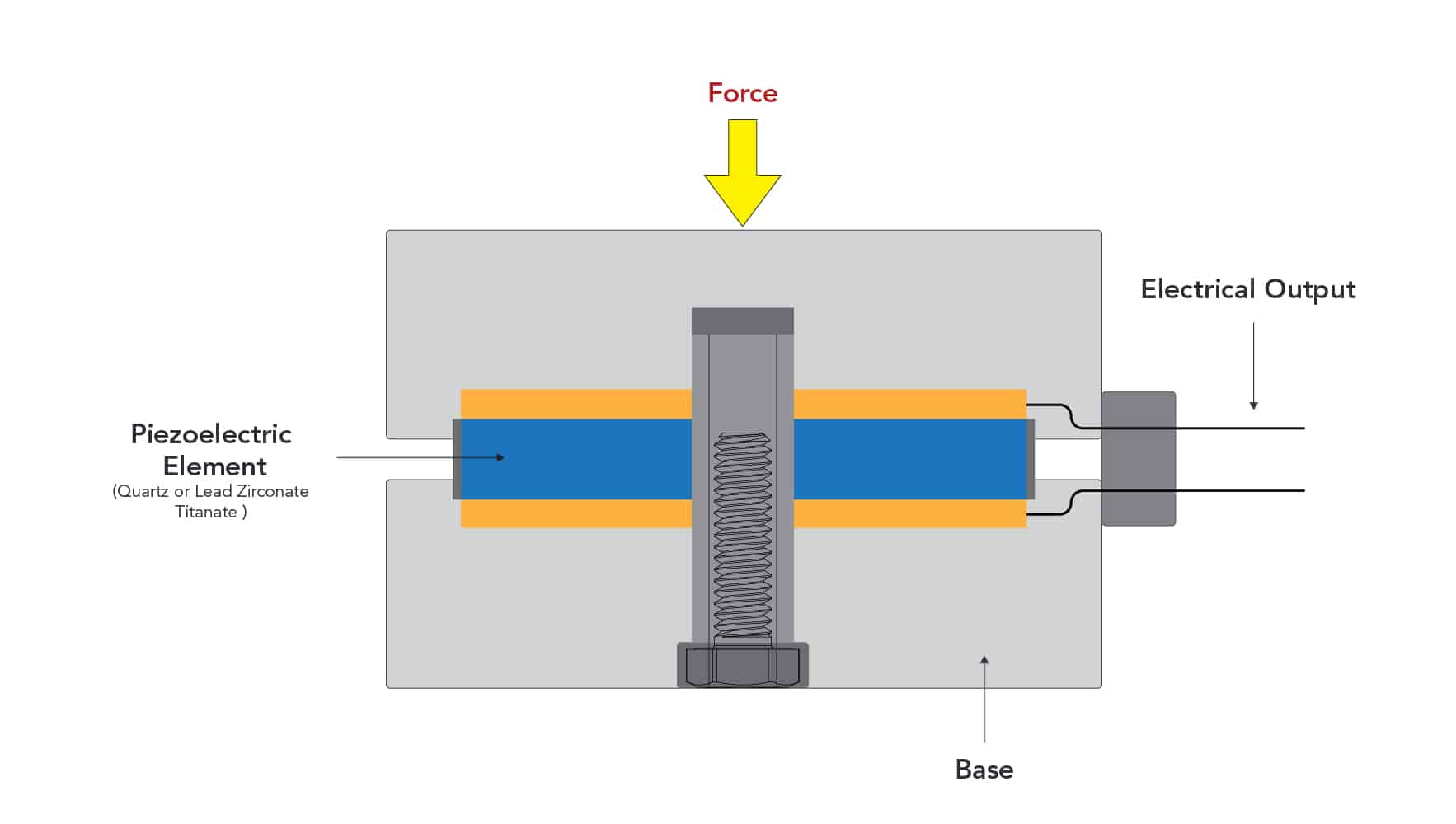

Piezoelectric load cells measure force based on the piezoelectric effect, where certain materials (such as quartz) produce an electric charge in response to applied mechanical stress.

When force is exerted, the piezoelectric element’s inherent properties cause it to generate a voltage proportional to that force. This immediate reaction is captured and converted into a readable electrical signal, typically by a charge amplifier.

Despite their quick response and high precision for dynamic loads, piezoelectric load cells are less suited for static measurements due to potential charge leakage over time. Nonetheless, their ability to rapidly detect force changes is beneficial for applications measuring transient force.

5. Vibrating Wire Load Cells

5.1 What are Vibrating Wire Load Cells?

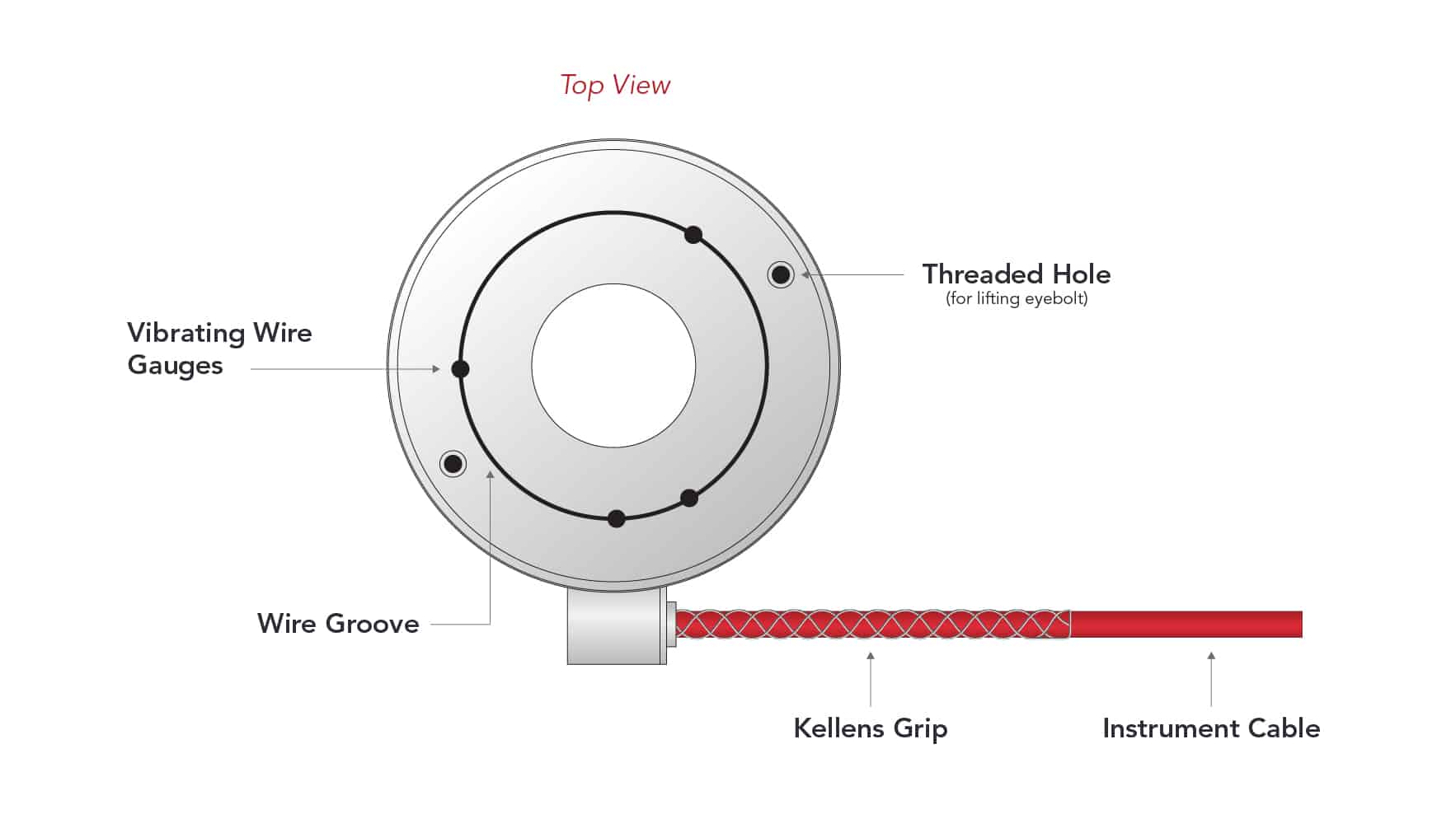

Vibrating wire load cells utilize the principle of frequency change in a tensioned wire to measure force. This type of load cell consists of:

Tensioned Wire: A metal wire that is anchored at both ends within the cell.

Magnetic Coil: Surrounds the wire, used to induce vibration and measure the wire’s natural frequency.

The mechanics behind vibrating wire technology involve plucking the wire with an electromagnetic field, causing it to vibrate. The vibration frequency changes in direct proportion to the tension in the wire, which varies with the applied force or load. This frequency shift is then converted into an electrical signal, which can be read and interpreted as a measurement of force.

Vibrating wire load cells are known for their stability and reliability over long periods and are less susceptible to drift than other types. However, they can be more complex to manufacture and may be sensitive to temperature variations, which can affect the wire’s tension and thus the accuracy of the frequency measurements. Their durability makes them suitable for geotechnical and long-term monitoring applications where environmental conditions can vary significantly.

Where are Load Cells Found?

Every household product has been weighed many times before it ends up in the hands of the consumer.

Load cells can be found anywhere that a force or weight needs to be measured, especially in applications where a higher level of precision or durability is needed. Load cells are used to measure everything from a few hundred tons or more to a few grams or less, essential to almost every industry that must handle physical products.

From production to delivery, load cells play a pivotal role.

To illustrate the integral role of load cells, consider the journey of a stack of A4 printing paper:

Load cells and force transducers are used from the point where a mechanical arm equipped with a load cell lifts and weighs a freshly felled tree, to the truck scales that determine the mass of the harvested timber in compliance with transportation safety and forestry regulations. Even in the paper processing plant, load cells are instrumental on conveyor systems, ensuring the raw fiber’s weight is monitored before processing. After production, the paper’s weight is meticulously checked to verify batch uniformity. Finally, as pallets of paper travel in and out of warehouses, load cells validate the cargo weight for inventory management, and when an order of pack of A4 paper is placed, it is weighed for accurate freight cost calculation before shipment.

Why are Strain Gauge Load Cells so Widely Used?

Strain gauge load cells are favoured for their precision, versatility, and reliability, making them indispensable in various industries. Their adaptability to measure a broad spectrum of weight or force ranges ranges—from milligrams to inch-pounds to kilotons—meeting the diverse requirements of numerous applications.

The precision of strain gauges, which translates minute physical deformations into electrical signals, ensures accuracy in weight and force measurement. This accuracy is critical for maintaining quality control across production lines and ensuring compliance with regulatory standards.

Durability is another key factor; strain gauge load cells are built to endure, capable of operating effectively in harsh environments and under severe industrial conditions. Their robustness translates to longevity and consistent performance, which is essential for continuous operations.

The relative cost-effectiveness of strain gauge load cells also adds to their widespread use. Strain gauge load cells offer a balance of high-quality measurements and affordability, which is vital for businesses looking to optimize their operations without excessive expenditure.

Furthermore, the ease of integrating these load cells into different systems and their scalability for customized applications allow for seamless adoption in existing technological setups. Their high sensitivity to weight changes ensures that even the slightest variations are captured, enabling precise process control.