Wind Turbine Blade Weighing

Gravimetric Quality Assurance Solution for Wind Turbine Blades

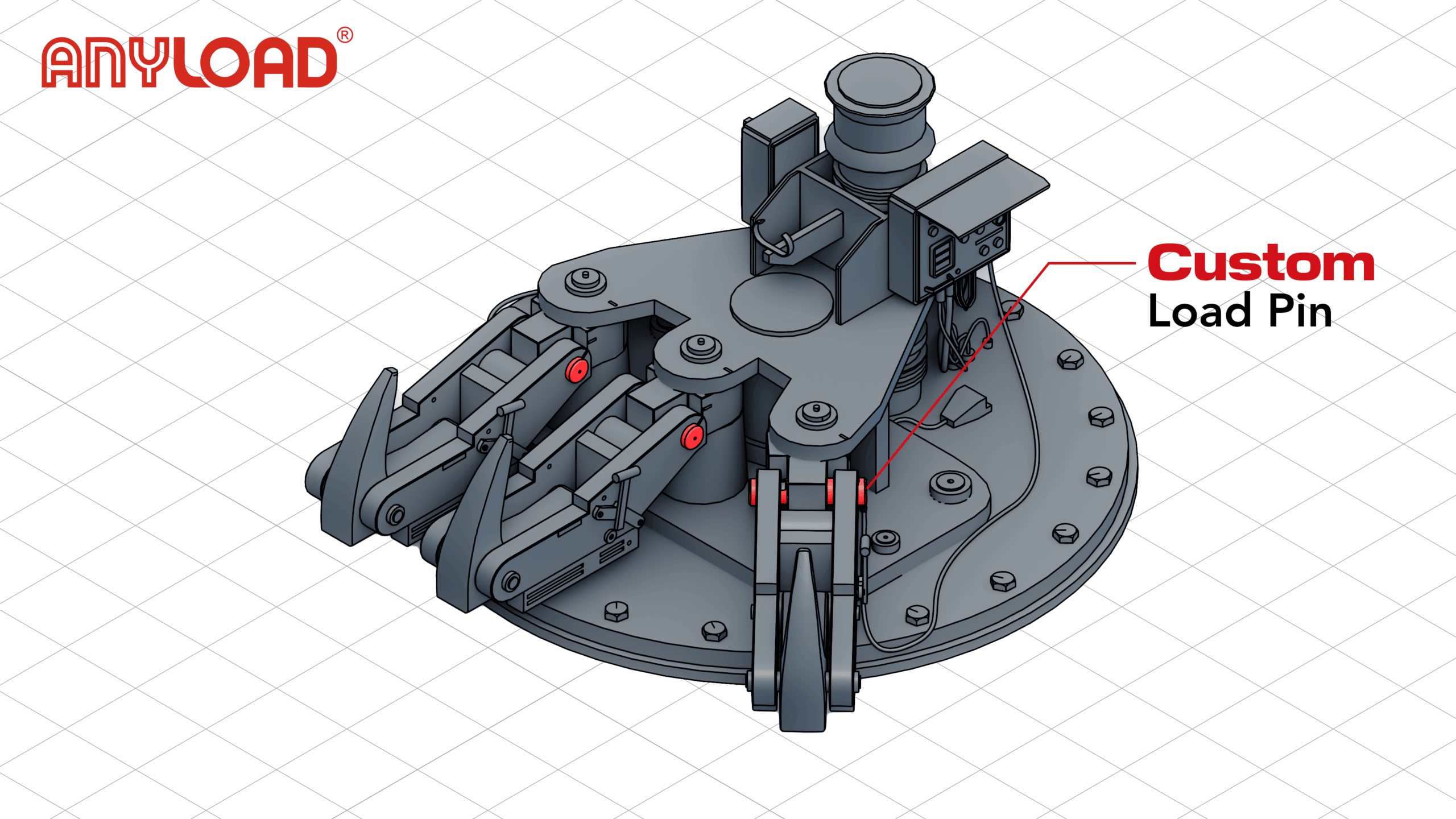

ANYLOAD applied industry-leading tension link technology to develop a critical system for ensuring consistency in wind turbine blade manufacturing.

Wind turbine blades must be precisely balanced in weight and centre of gravity to minimize weight imbalances that can significantly shorten the expected service lifespan of wind turbines. Imbalanced blades can exert uneven forces on the rotor hub, leading to misalignment and material fatigue failures in the gear box and other turbine components.

How it works:

- Larger blades can weigh more than 50t yet a small imbalance of a few hundred kilograms can cause additional wear-and-tear on turbine gears.

- A weighing system is needed to measure a large, heavy structure (turbine blades can exceed 100m in length) extremely accurately.

- ANYLOAD developed a wireless tension link and custom mounting assembly with a certified high safety factor and calibrated to measure with extreme precision. For a 50t load, ANYLOAD tension link only had a margin of error of ±5kg.

- Blade manufacturer is able to use these measurements to correct each turbine to a consistent weight to minimize damage caused by vibrations to wind turbine components.

- A periodic service schedule for each load cell to be recalibrated and the system to be refurbished maintains continuous uptime and accuracy.

Custom Solution

ANYLOAD worked closely with the manufacturer’s global QA and engineering teams to develop, test, manufacture, and support a system that helps to ensure a longer lifespan for wind turbines.

Featured Products

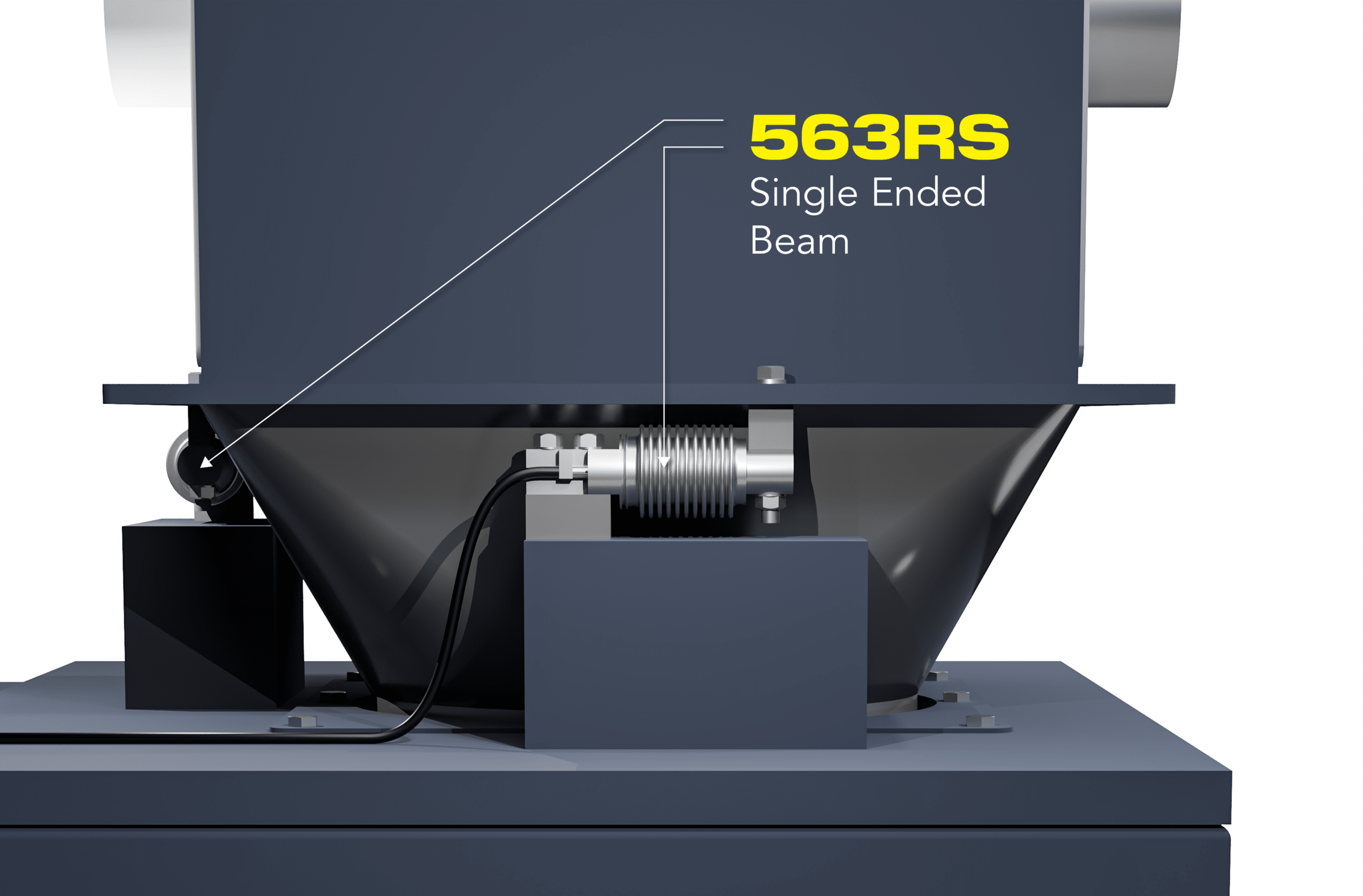

110BH

Tension Link

See standard version.

- Capable of >20,000 division accuracy (±0.005% of full scale)

- High safety factor (breaking overload: 400% of full scale)

- Wireless connectivity to indicator and large LED remote display

The patented 110BH standard tension link is already the world’s most accurate (OIML C6) legal for trade tension link and can be calibrated for even higher resolution while maintaining excellent natural linearity and vibration resistance.

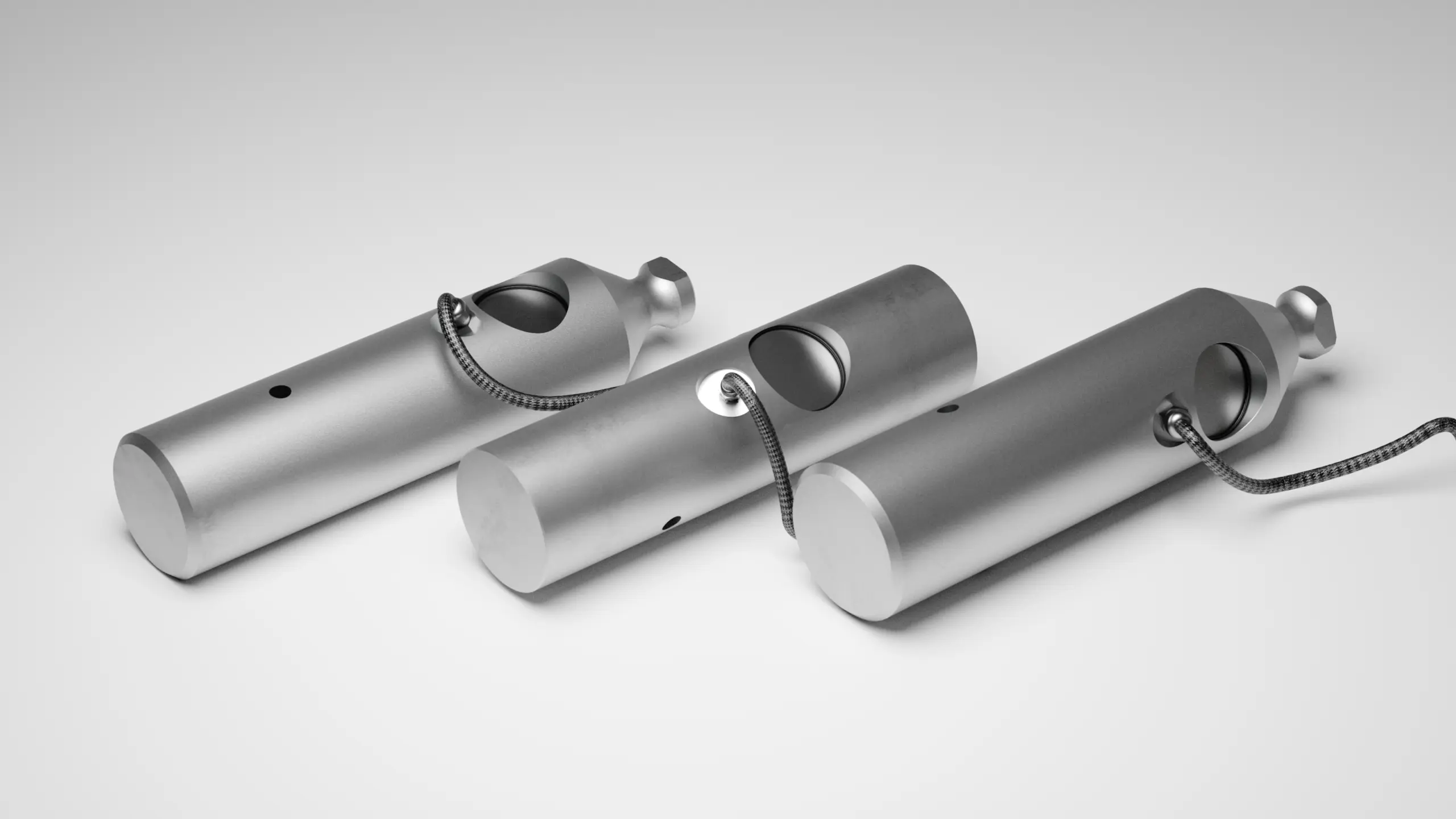

CUSTOM

Shackle

- Proprietary design for significantly improved repeatability

- Mechanical safety CE certification by DEKRA

Sets of custom mounting assemblies were required as standard shackle designs did not allow for high repeatability measurements. These assemblies were tested and ISO17025 calibrated in tandem with the tension link load cells and instrumentation.

Agricultural Weighing Solutions

How agricultural industry uses our load cell for cart and mobile equipment for optimal result

Increase Turbine Life Span

Gravimetric quality assurance solution for wind turbine blades studies

Bag Filling Machine Load Cell

Bag filling and other process weighing and control system for maximal efficiency