Livestock

Reliable Weighing from Hatch to Market

Weighing systems are essential to effective livestock management, from feed optimization and health monitoring to market compliance and traceability. Whether weighing chicks, pigs, or full-grown cattle, accurate force measurement supports data-driven decisions that improve productivity, animal welfare, and operational efficiency.

ANYLOAD supplies load cells and weighing components built for the diverse demands of livestock environments—barns, pens, mobile weigh trailers, and on-farm processing lines.

Applications Include:

- Poultry & Swine Weighing → Monitor Growth from Hatch to Harvest Monitor bird and hog weight in cages, pens, or conveyors to support ration control, growth rate analysis, and processing readiness.

- Cattle & Heavy Livestock → Market Compliance & Herd Management Weighing using floor, alleyway, platform or chute-mounted systems for large animals in commercial or on-farm operations.

- Veterinary & Breeding → Monitor Heath & Performance Animal monitoring, dosing, and weight-based health metrics.

- Automated Barn Systems → Precision Feeding & Automation Integrate load cells into feed bins, autonomous feeders, barn robotics, mixers, and auger systems to enable automated workflows

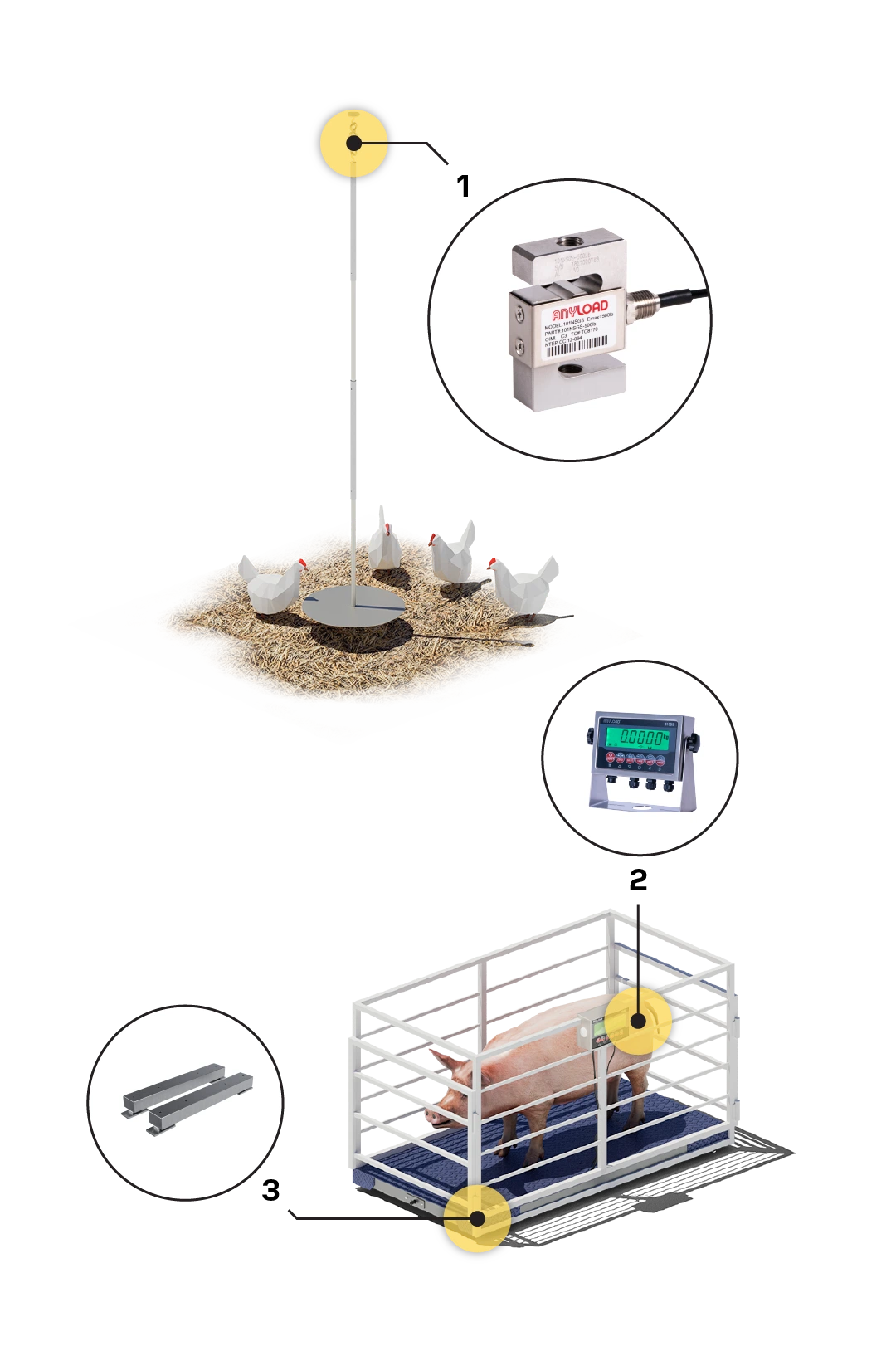

Poultry & Swine Weighing

Accurate weight monitoring is vital in poultry and swine operations to manage feed conversion, track growth, and meet processing targets. ANYLOAD load cells deliver fast, reliable performance in high-throughput environments such as pens, cages, and conveyors. Designed for continuous use, they help optimize feeding strategies and production efficiency.

Challenges & Solutions

- High-Cycle Weighing: Poultry and swine systems demand rapid, repeatable measurements. ANYLOAD sensors offer fast response, high resolution, and stable signals for both static and in-motion weighing.

- Contaminants & Washdown: Barns expose equipment to dust, ammonia, and moisture, requiring corrosion-resistant and washdown designs.

- Animal Movement: Weighing accuracy must be maintained despite motion and shifting loads. Our solutions include filtering, overload protection to ensure consistent results.

To Learn More:

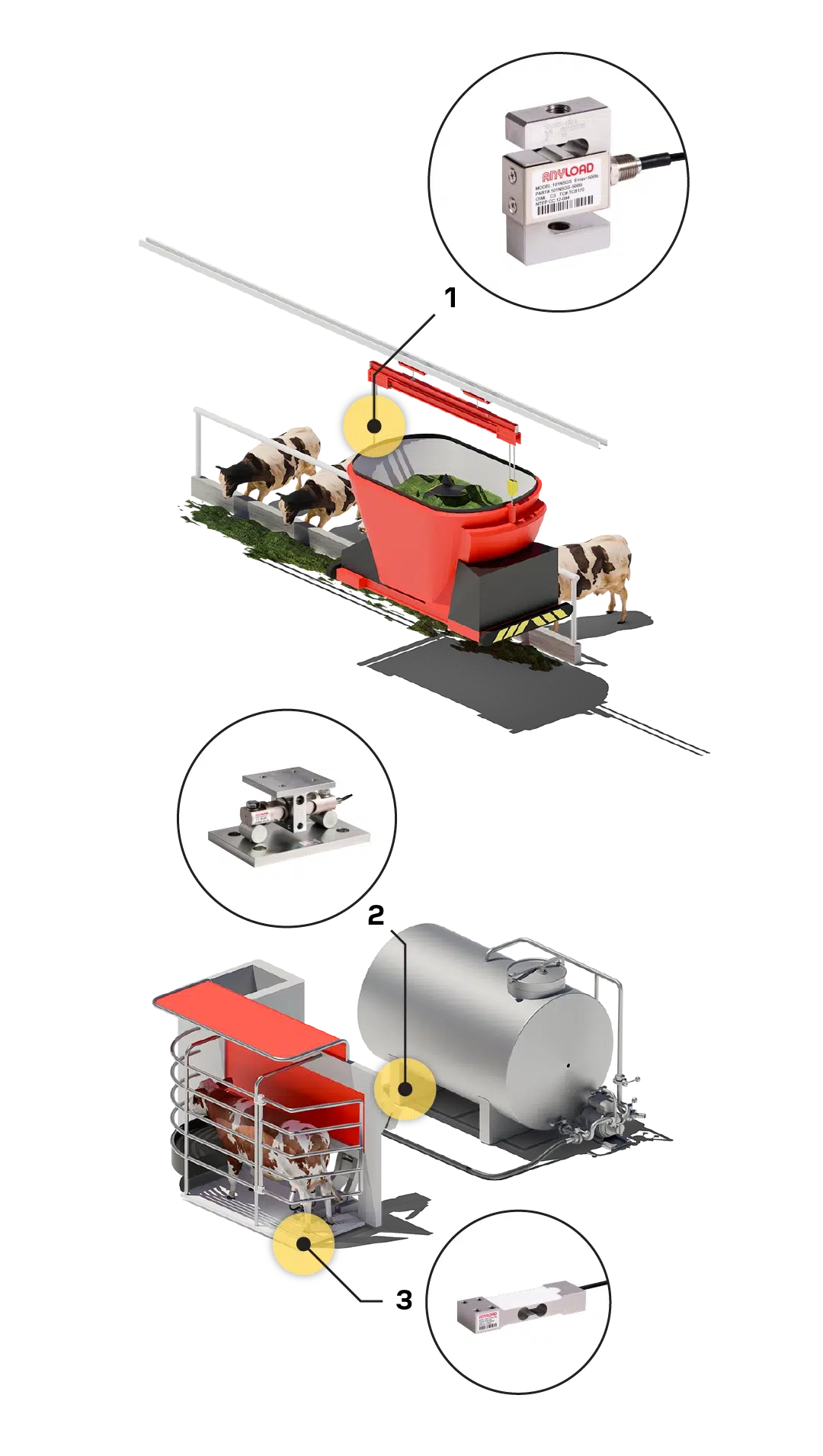

Automated Barn Systems

Automation is transforming livestock operations with systems designed to reduce labor, increase precision, and improve animal welfare. ANYLOAD supplies robust, accurate load cells and force sensors that support a wide range of automated barn equipment—from robotic feed pushers and TMR mixers to rotary milking platforms, bedding dispensers, and smart overhead feed rails.

Our sensors enable real-time feedback, motion control, and system diagnostics, ensuring automation runs smoothly, safely, and with full data transparency. Whether fixed, mobile, or suspended, these systems depend on reliable force measurement to maintain throughput and reduce downtime.

Challenges & Solutions

- Multi-Point Load Sensing: Automated systems often require multiple synchronized force inputs across moving platforms, rails, or conveyors. ANYLOAD offers scalable solutions with consistent performance across high-cycle operations, supporting smart control algorithms and safety shutoffs.

- Continuous Operation in Harsh Environments: Dust, moisture, manure, feed particles, and cleaning agents are constant in barn settings. ANYLOAD sensors are IP-rated, hermetically sealed, and corrosion-resistant to perform reliably under daily washdowns and airborne contaminants.

- Integration: Smart barns rely on unified control. ANYLOAD sensors support analog outputs (e.g. 4–20 mA, 0–5 V) and digital protocols including CAN bus, Modbus RTU, and other fieldbus standards for seamless integration into automation controllers and OEM platforms.

- Dynamic Conditions: Mobile and suspended systems must react to changing terrain, animal interaction, and mechanical resistance. ANYLOAD force sensors detect overloads and wear conditions to help protect components and animals while maintaining accurate dosing and material flow.

To Learn More:

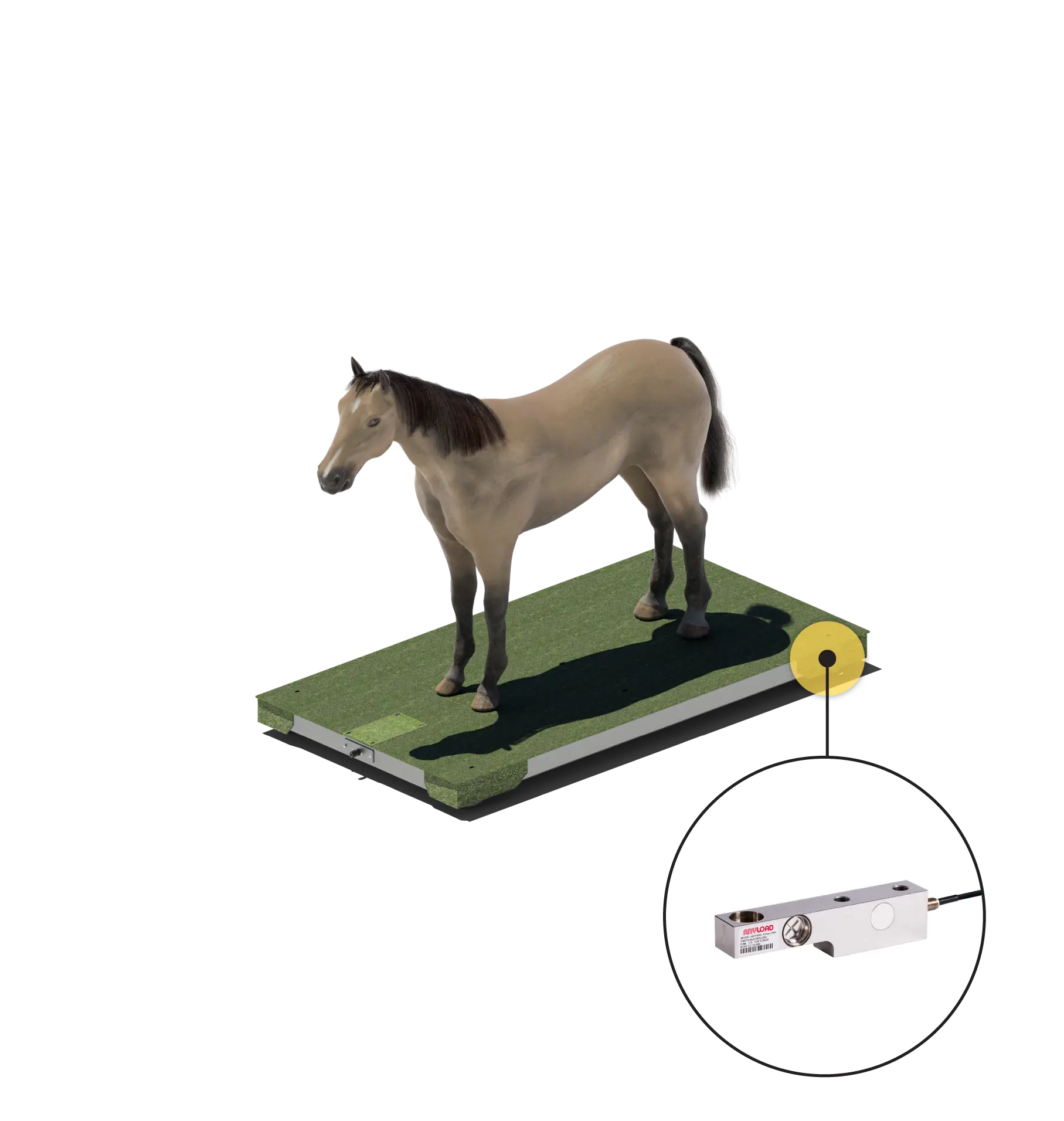

Veterinary

ANYLOAD supplies precision load cells for advanced veterinary and breeding systems where performance is critical. From racehorse scales and equine surgical beds to force measurement platforms used in breeding programs or research, our sensors support high-value animal care, diagnostics, and data collection.

Challenges & Solutions

- High-Precision Requirements: Racehorses, breeding stock, and research animals demand tight tolerances and stable readings.

- System Integration: Veterinary beds, rehabilitation platforms, and lab equipment often require custom mounting or output signal compatibility.

- Data Integration: Veterinary environments call for hygienic, impact-resistant components requiring sealed, coated, and fatigue-rated solutions to handle repeated loading, moisture, and disinfectants common in clinical and breeding settings.

To Learn More:

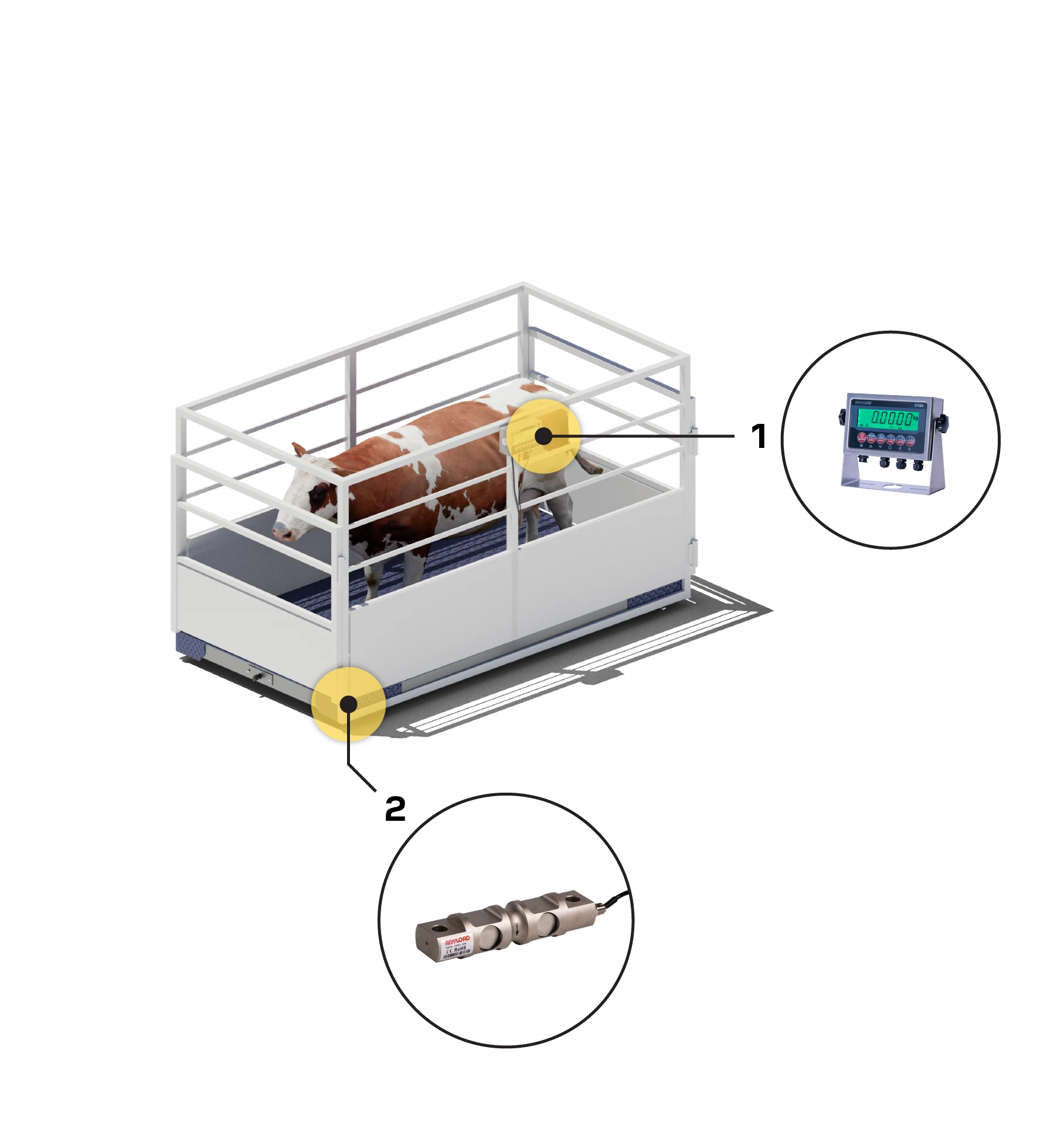

Cattle & Heavy Livestock

Weighing large animals is essential for tracking health, managing inventory, and ensuring compliance with market and regulatory standards. ANYLOAD load cells provide high-capacity, precision performance in chute-mounted, alleyway, and platform-scale systems. Built to withstand animal impact, uneven loads, and tough environmental conditions, our sensors ensure consistent results in both commercial and on-farm operations.

Challenges & Solutions

- Large Capacity Loads: Large livestock from calves to full-grown cattle require rugged sensors with excellent repeatability and reliability.

- Impact & Load Shifting: Livestock scales face dynamic, side-loaded impacts. Our weighing systems are designed with shock protection and lateral load tolerance to maintain accuracy and structural integrity.

- Outdoor & Corrosive Environments: Scales are exposed to manure, moisture, cleaning agents, and extreme temperatures. ANYLOAD sensors feature hermetic sealing, stainless or coated construction, and IP-rated housings for long-term field durability.

View Products: