Agri-Food Processing

Efficiency, Hygiene, and Automation

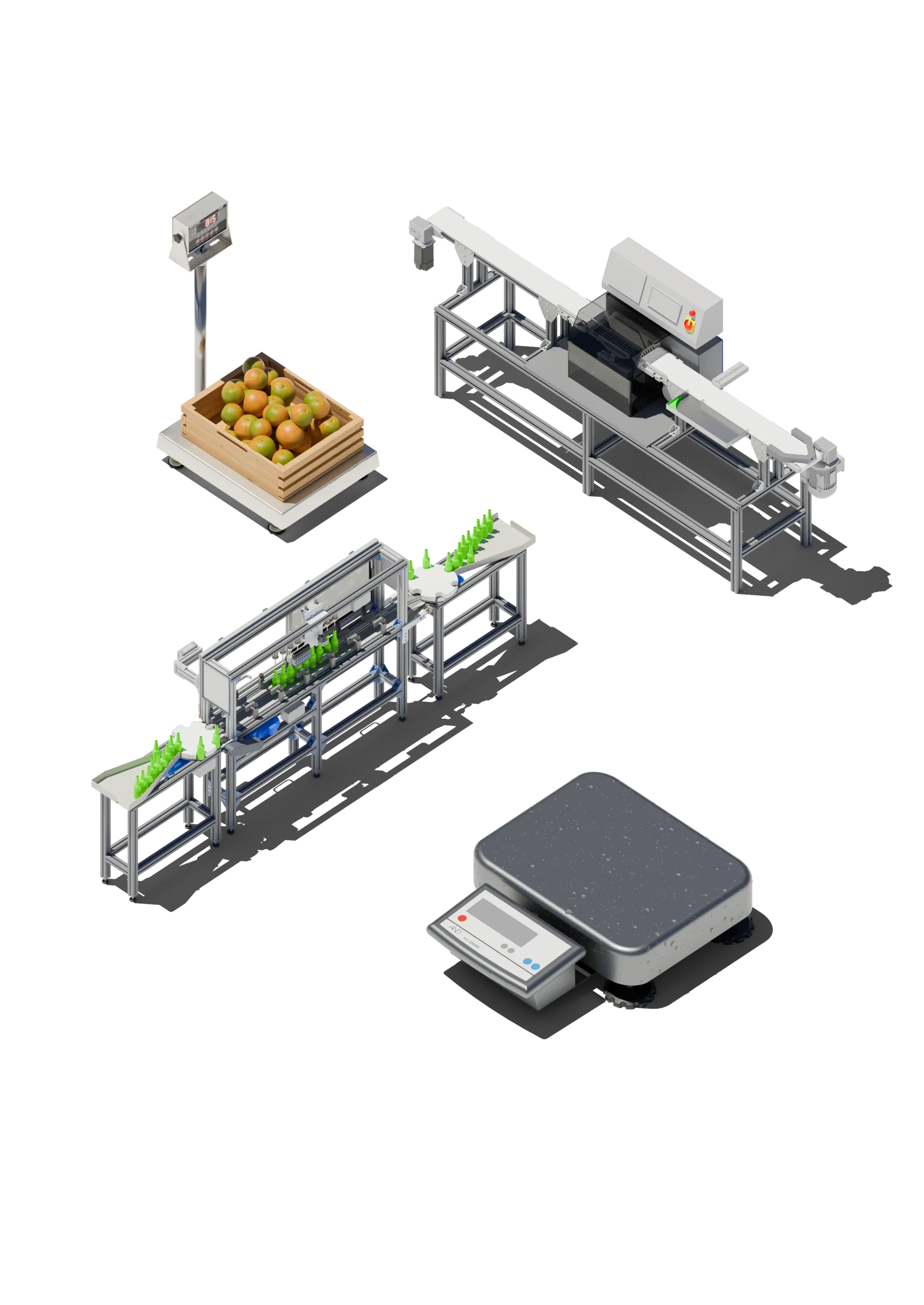

Accurate weight measurement is critical at every stage of agricultural food processing—from raw ingredient intake and portioning to automated checkweighing and final packaging.

ANYLOAD supplies food-safe, washdown-capable load cells and weighing components designed for ingredient batching, process control, and in-line automation. Our solutions are built for high-accuracy performance under wet, corrosive, and fast-paced operating conditions.

Whether weighing small portions, monitoring flow, or verifying package weight, ANYLOAD sensors integrate easily with checkweighers, conveyors, mixers, and filling systems, delivering precision, durability, and regulatory compliance for food environments.

Applications Include:

- Hygienic & Washdown Environments: Stainless steel, IP69K load cells for use in areas requiring regular high-pressure washdown, chemical cleaning, or direct food contact.

- Portioning & Weigh Stations: Compact, high-accuracy load cells for tabletop scales, cutting tables, and tray portioning, ideal for protein, produce, and specialty food operations where precision and hygiene are critical.

- Batching, Mixing & Filling Systems: Weighing solutions for ingredient hoppers, dosing bins, mixing vessels, and filler tanks to enable precise formulation, flow control, and volumetric-to-gravimetric conversion.

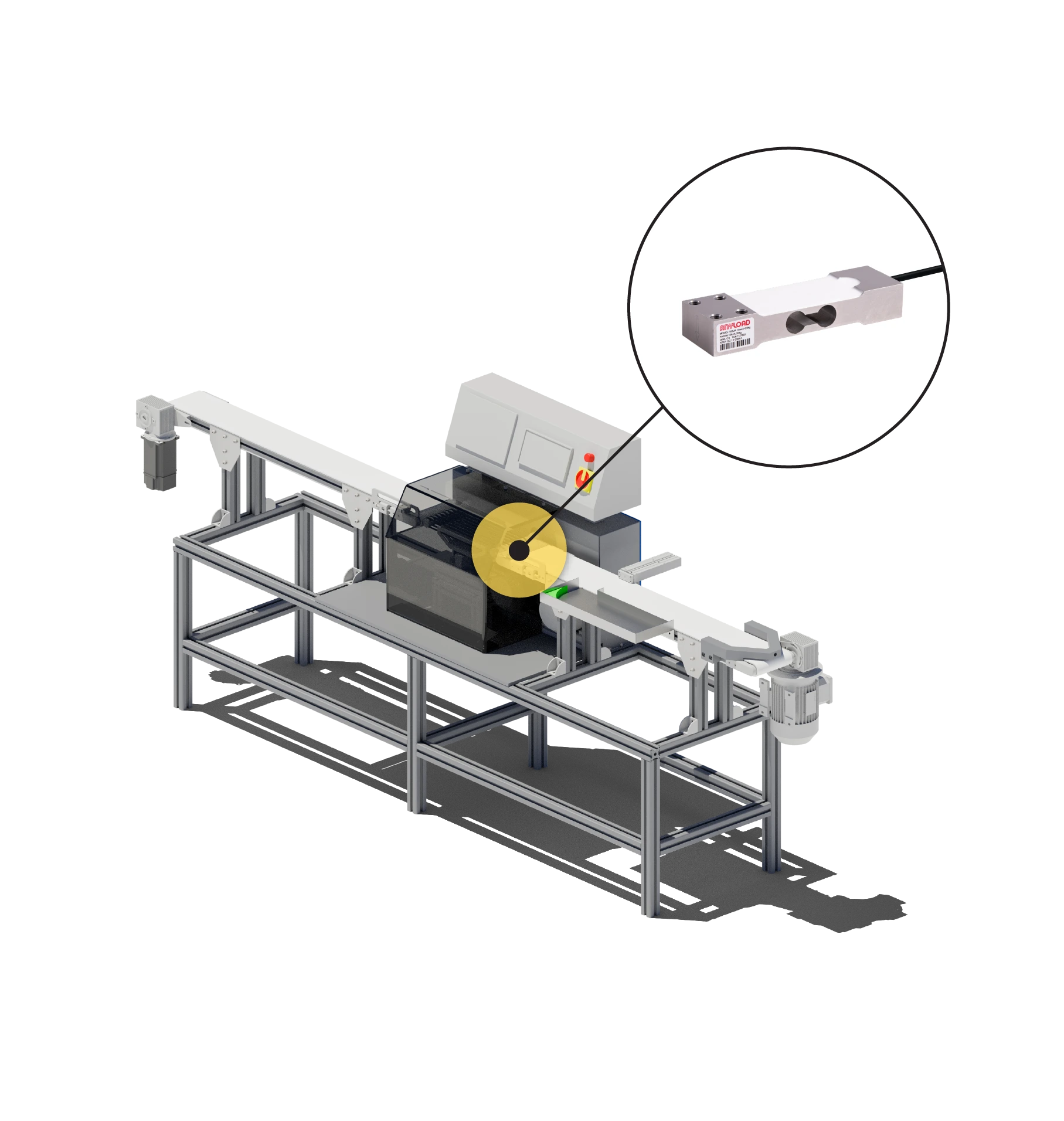

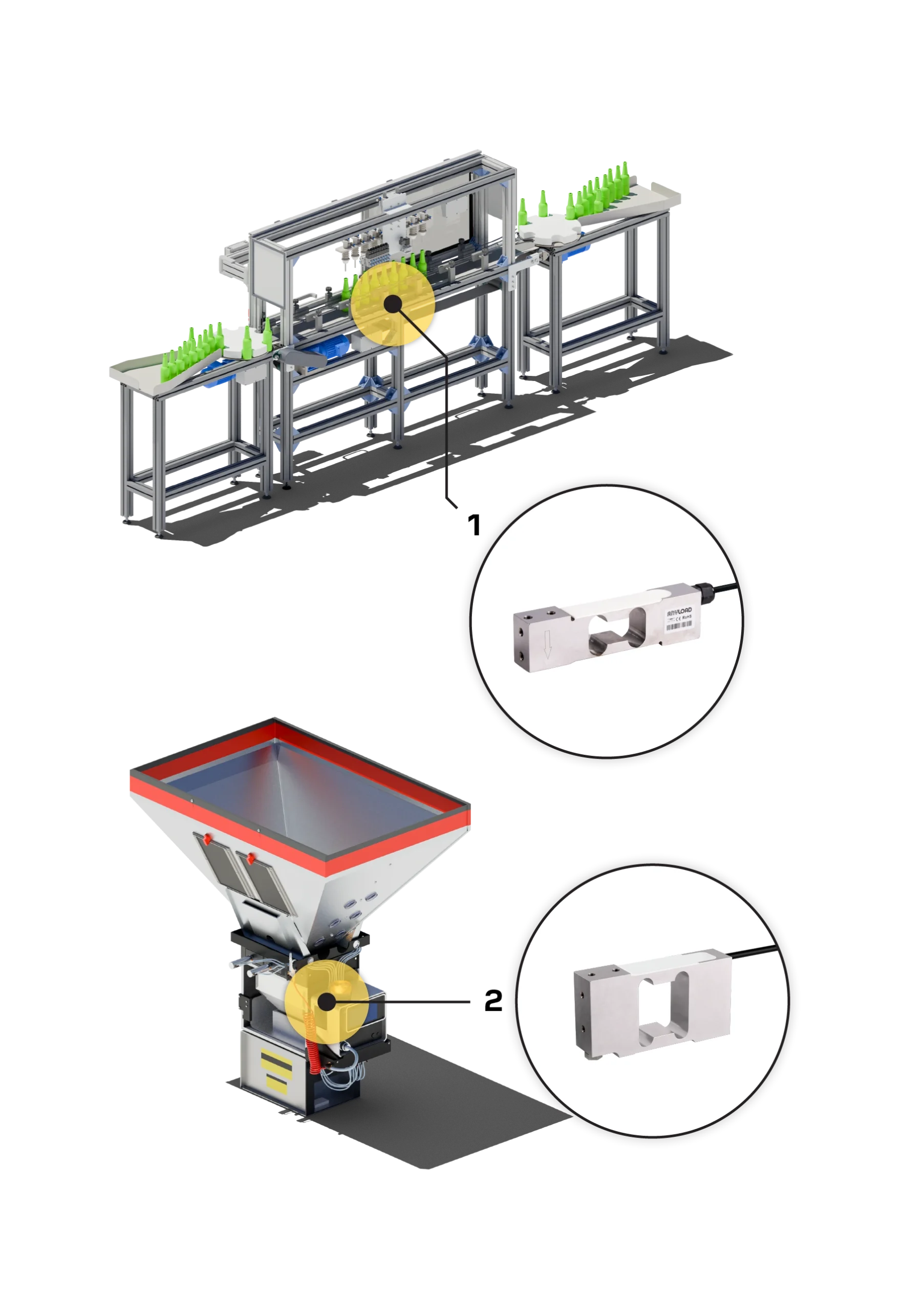

- Checkweighing: Integrate load cells into high-speed in-line checkweighers to meet regulatory weight limits, prevent give-away, and ensure quality control in final packaging zones.

Hygienic & Washdown

Weighing systems in food-contact zones must meet strict hygiene and cleanability standards while enduring aggressive sanitation routines and thermal exposure. ANYLOAD designs and manufactures washdown-capable load cells and mounting components using sanitary design principles (e.g. radiused surfaces, crevice-free housings, minimal contact area), drawing on experience with NSF-compliant and food-safe certified systems.

We are ISO 13485–certified for medical device design and manufacturing, bringing a higher standard of process control and traceability to hygienic applications. With in-house ingress and corrosion testing equipment, we validate IP ratings and resistance to chemical agents common in food plants, and offer custom engineering for high-temperature washdown environments.

Challenges & Solutions

- Ingress Protection & Sealing Integrity: Washdown equipment must resist water, steam, and debris under pressure. ANYLOAD provides load cells rated up to IP69K.

- Corrosion & Chemical Exposure: Acids, alkalis, and cleaning agents degrade unprotected materials. Our solutions use 316 or 17-4 stainless steel, food-grade seals, and chemical-resistant cable glands to withstand long-term exposure in CIP and COP systems.

- Food Safety: ANYLOAD applies sanitary design principles aligned with HACCP, FSMA, and NSF requirements. We support low-porosity surface finishes, open-frame mounting designs, and documentation for audit readiness and OEM compliance.

- High-Temperature: ANYLOAD offers high-temperature load cell and sensor variants engineered for cooking, steaming, or post-wash thermal cycling.

To Learn More:

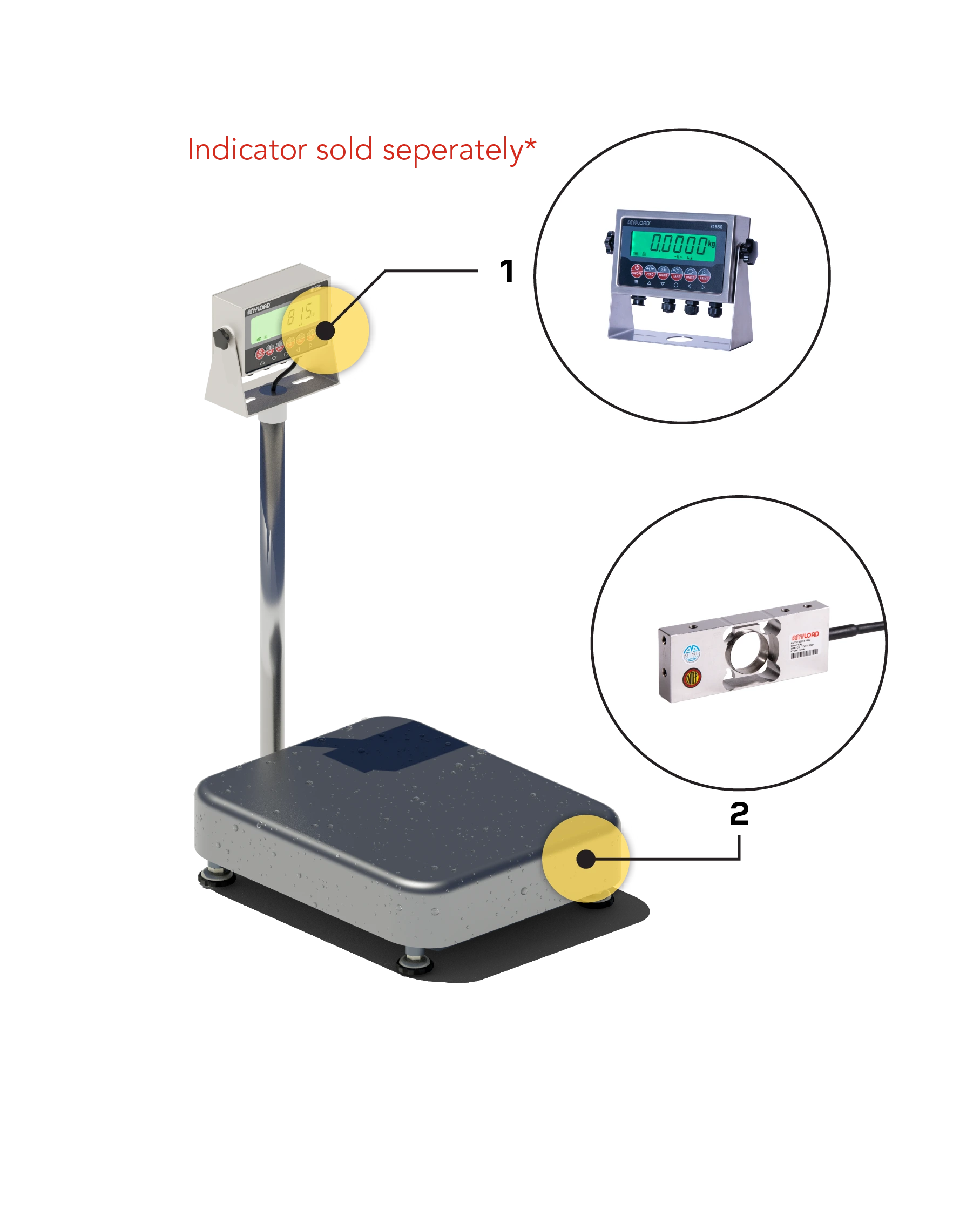

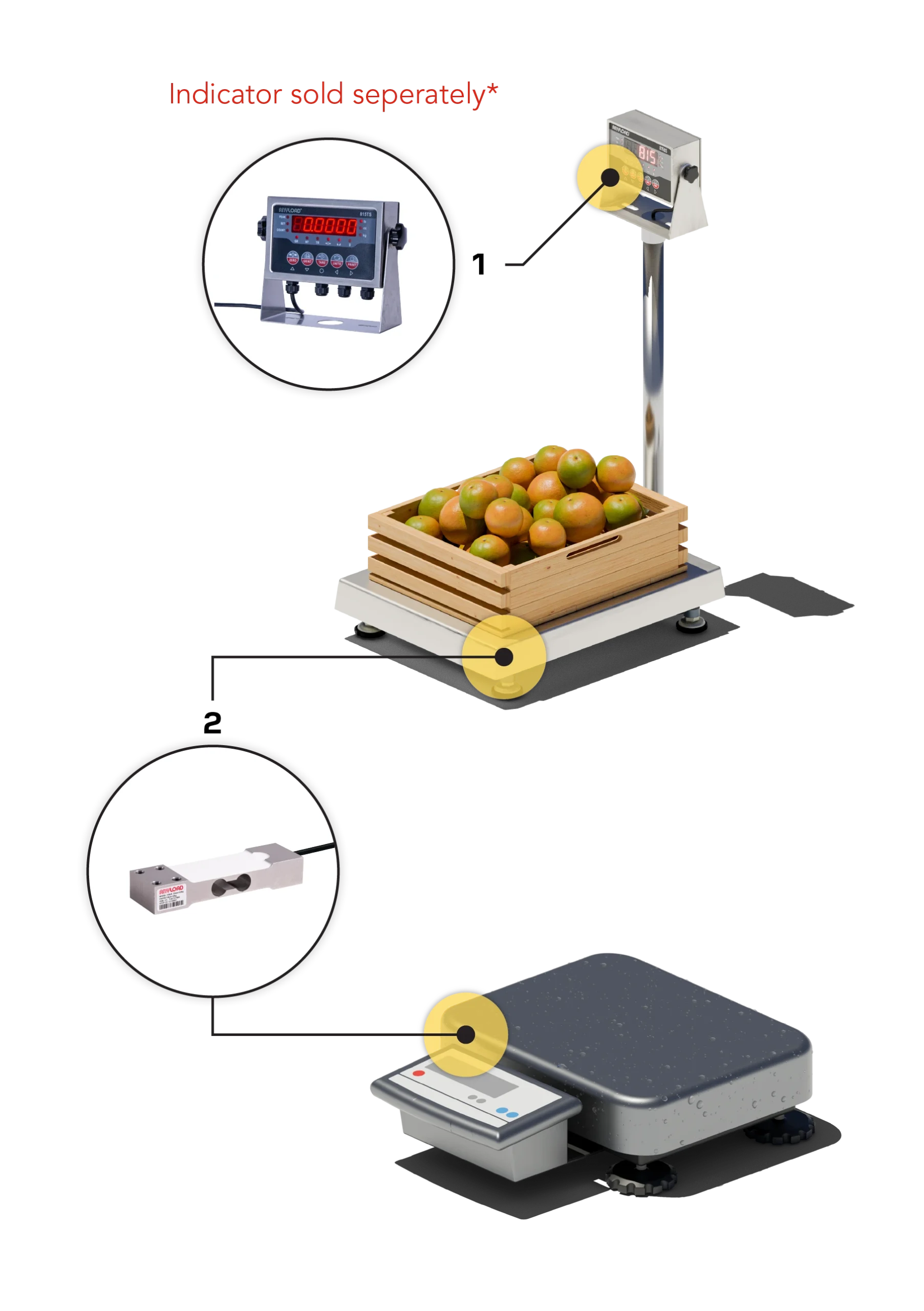

Portioning

ANYLOAD provides load cells and subassemblies designed for bench-scale portioning, ingredient prep, and end-of-line packaging stations in food processing environments. We specialize in high-accuracy load cells and custom solutions integrated into OEM platforms, including systems for pizza assembly, protein portioning, and tray packing.

Challenges & Solutions

- Accuracy & Resolution at Low Capacities: Portioning tasks often require precise readings in the 1–500 kg range. ANYLOAD offers single-point and low-profile load cells with high linearity and repeatability, suitable for bench-scale applications and compact weighing systems.

- Durability in Daily Use: Frequent loading, impact, and washdowns can degrade performance. Our sensors are fatigue-rated, available with IP69K, and constructed with stainless or coated finishes for longevity in food processing environments.

- Custom OEM Integration: Many food processors require weighing integrated directly into prep stations or portioning equipment.

- Hygiene Standards: We provide food-safe options with smooth, crevice-free surfaces, food-grade seals, and sanitary design support.

To Learn More:

Batching, Mixing, Filling

ANYLOAD provides robust load cells and assemblies for use in ingredient batching, automated mixing vessels, and liquid or semi-solid filling systems. Our sensors are trusted in feed mills, bakeries, sauce production, dairy blending, and other food processing environments where weight-driven dosing and formulation are key to quality and throughput.

Designed for stationary and suspended vessels, our solutions ensure consistent product flow, enable volumetric-to-gravimetric transitions, and support automated control of multi-ingredient batching systems.

Challenges & Solutions

- Dynamic Loading During Fill & Discharge: Ingredient flow causes shifting loads and surges that affect accuracy. ANYLOAD load cells are fatigue-rated, with fast response times and paired with specialized weigh modules that maintain stability under fluctuating conditions.

- Mechanical & Mounting Constraints: Mixers, hoppers, and tanks vary in size and configuration. ANYLOAD offers a wide range of shear beam, single-point, and S-type load cells with custom mount kits for both top-mounted and suspended systems.

- Process Automation Integration: Accurate weight data must feed into control logic in real time. Our sensors are available with analog (4–20 mA, 0–10 V) and digital (CAN bus, Modbus, RS485) outputs for seamless connection to PLCs, batching controllers, and SCADA platforms.

To Learn More:

Checkweighing

ANYLOAD supplies precision load cells for use in automated checkweighing systems, where speed, accuracy, and regulatory compliance are critical. Our sensors are designed to perform in high-throughput food packaging environments, supporting both fixed-weight and variable-weight product lines for meats, baked goods, produce, dairy, and packaged items.

Engineered for easy integration into OEM checkweighers or custom conveyor systems, ANYLOAD load cells ensure consistent performance under rapid cycling, washdown exposure, and packaging-induced vibration.

Challenges & Solutions

- Speed & Accuracy Under Motion: Checkweighers must deliver accurate readings within milliseconds as products pass across the belt. ANYLOAD sensors offer high-frequency response, fast stabilization times, and excellent linearity for in-motion weighing.

- Packaging Vibration & Belt Dynamics: Conveyor movement and product variability can introduce mechanical noise. Our load cells feature built-in damping, and we offer mechanical isolation kits to reduce vibration transfer and ensure stable weight output.

- Regulatory Compliance & Giveaway Reduction: Processors must meet legal weight tolerances while minimizing overfill. ANYLOAD sensors deliver repeatable, traceable measurements that help reduce product giveaway and support compliance with local trade regulations.

View Products: