Guide to Vessel Weighing – Basics

Last Updated On May 22nd • 15 min read

The weighing of tanks, hoppers, silos, and process vessels is a critical aspect of inventory management, process control, and material handling across industries such as food processing, chemical manufacturing, agriculture, and pharmaceuticals.

Vessel weighing systems generally integrate load cells directly into the vessel’s support structure, allowing for continuous weight monitoring without disrupting operations. However, achieving accurate and reliable measurements requires careful consideration of structural design, product selection, environmental influences, and installation techniques.

This guide provides an in-depth overview of vessel weighing, from understanding different vessel types and their challenges to best practices for load cell selection, installation, and calibration.

1. Purpose of Vessel Weighing

Vessel weighing systems serve a variety of purposes, depending on the industry and application. Unlike belt scales or flow meters that measure material movement, vessel weighing provides a direct, highly accurate measurement of stored or processed material, making it an essential tool for the following applications:

- Inventory Management & Material Tracking

- Used in bulk storage facilities, grain silos, and chemical plants to monitor material levels in real time.

- Eliminates the need for manual level checking or unreliable ultrasonic/radar sensors.

- Helps prevent shortages or overfills, ensuring optimal stock levels for production.

- Process Control & Batching

- Common in industries like food & beverage, pharmaceuticals, and cement production, where ingredients must be measured and dispensed precisely for consistent quality.

- Enables automated dosing and batching of exact portions.

- Reduces material waste by minimizing overuse or underuse of ingredients.

- Legal-for-Trade Weighing

- Required in applications where materials are bought or sold by weight, such as in commercial grain elevators, bulk chemical distribution, and toll processing.

- Ensures compliance with Weights & Measures regulations, preventing financial disputes over product quantities.

- Typically demands high-precision load cells and certified weighing instruments to meet regulatory standards.

- Safety & Overload Protection

- Helps prevent structural failures or overfills by detecting excessive loads.

- Useful for applications with high-value or hazardous materials, such as pressurized chemical tanks or industrial gas storage.

- Continuous Monitoring for Process Optimization

- Provides real-time weight feedback for systems with dynamic material flow (e.g., mixing vessels, fermenters, or batch reactors).

- Allow for predictive maintenance, detecting changes in weight trends that may indicate leaks, blockages, or abnormal material usage.

- Supports automated refilling and discharge control, optimizing process efficiency and reducing manual intervention.

2. Type of Vessels

Vessel weighing applies to a wide range of industrial storage and processing containers, each with different requirements based on size, material, and function. Whether weighing a chemical reactor, grain silo, or ingredient hopper, understanding the vessel type is critical for accurate load cell selection and system design. Below are the most common vessel types used in weighing applications:

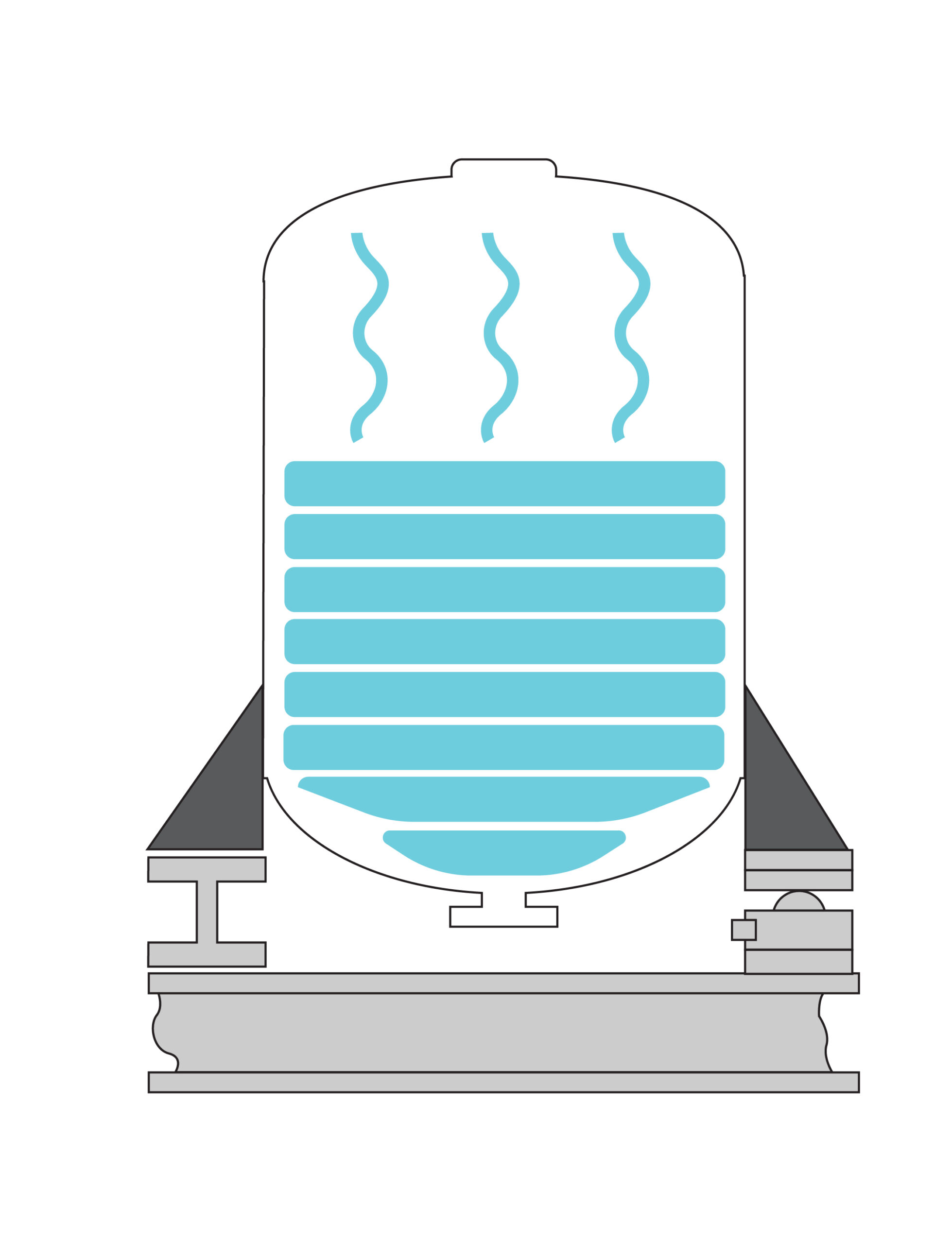

- Tank: Typically closed containers designed for storing or processing liquids, gases, or free-flowing solids. Tanks vary in size from small residential propane tanks to large industrial storage tanks holding thousands of gallons or tons of material. In industrial settings, they are used in applications such as chemical storage, fuel holding, and food processing.

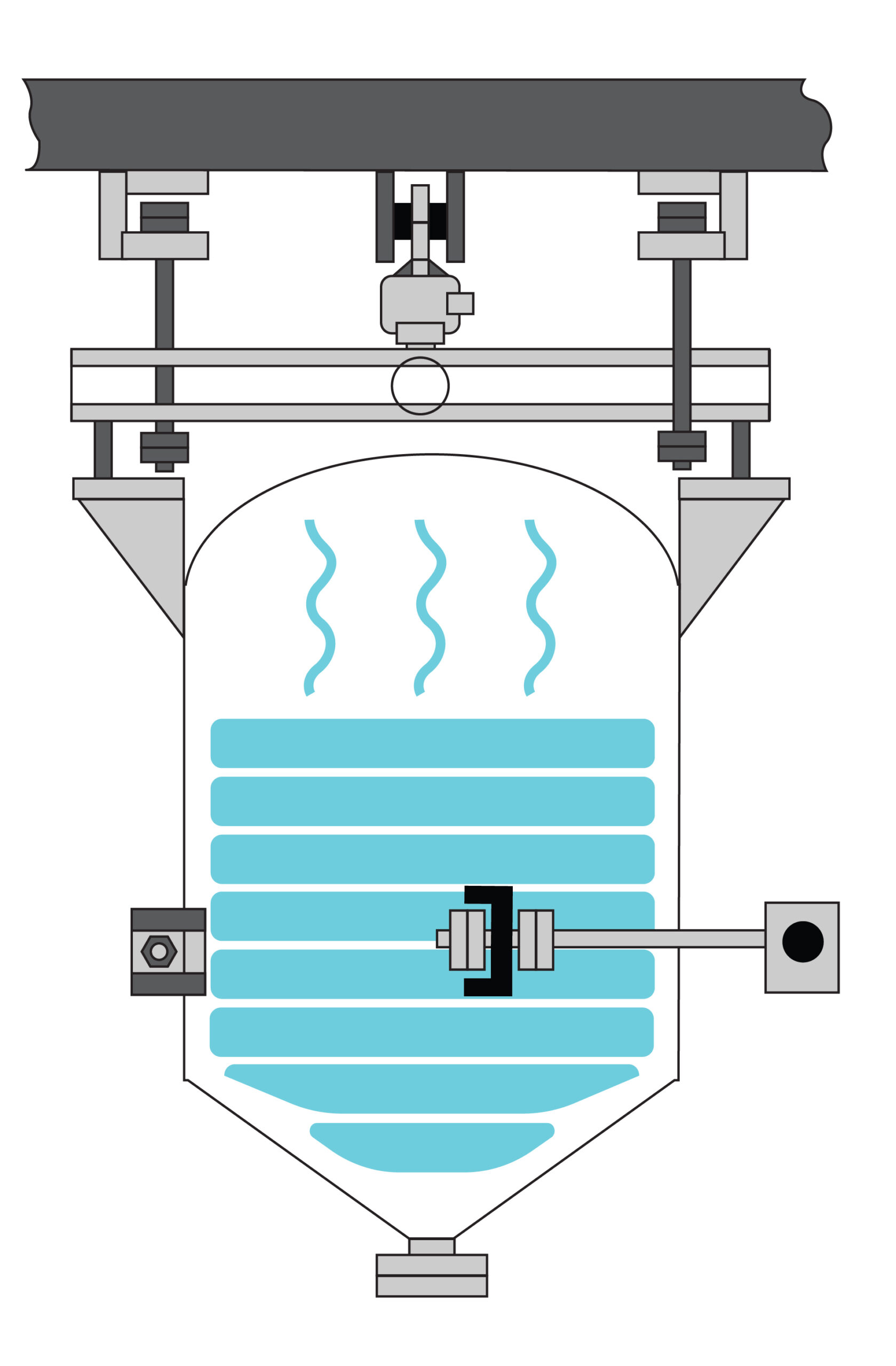

- Hoppers: Usually open-top containers, hoppers are commonly used for handling powered or granulated materials such as cement, flour, or plastic pellets. Often part of a continuous process, ingredient hoppers may dispense materials in controlled batches or collect raw materials from upstream processes in manufacturing.

- Silos: Large vertical storage vessels, silos are primarily used for bulk material storage in industries such as agriculture, mining, and cement production. A grain silo, for example, can store hundreds of tons of wheat, corn, or soybeans, while an industrial silo may hold cement powder or bulk chemicals for transport or processing. Silos are often outdoor structures, requiring weather-resistant load cell installations.

- Process Vessels & Reactors: More complex tanks equipped with integrated processing functions such as mixing, heating, cooling, or chemical reactions. Reactor vessels in chemical and pharmaceutical manufacturing require high-precision weight measurement to monitor reaction conditions, batch consistency, and material usage. Vessel weighing systems must account for factors like thermal expansion, agitation forces, and process piping constraints to ensure accurate readings.

Vessel weighing systems are used in various industrial applications, but despite differences in design and function, most follow similar weighing principles. Load cells are typically installed either:

At the support points of the vessel – mounted under the legs, frame, or base of the structure so that the vessel is supported by the load cells. This is common for tanks, silos, and process vessels.

In a suspended configuration – where the vessel hangs from load cells, such as ingredient hoppers or smaller batch hoppers, allowing gravity to act directly on the load cells.

3. Why Load Cells Are the Preferred Solution for Vessel Weighing

When it comes to measuring material quantities in tanks, hoppers, silos, and process vessels, various technologies exist, including flow meters, pressure sensors, and level indicators. However, load cells remain the most accurate, reliable, and versatile solution, particularly for applications requiring high precision, minimal maintenance, and legal-for-trade compliance.

Many alternative methods rely on indirect measurement techniques, such as estimating material weight based on fluid pressure, material level, or flow rate. These methods often require contact with the material, exposing sensors to corrosion, buildup, or mechanical wear. In contrast, load cells measure weight externally, with no need for direct contact with the contents of the vessel, making them highly durable and adaptable to a wide range of materials and environments.

Limitations of Alternative Measurement Methods

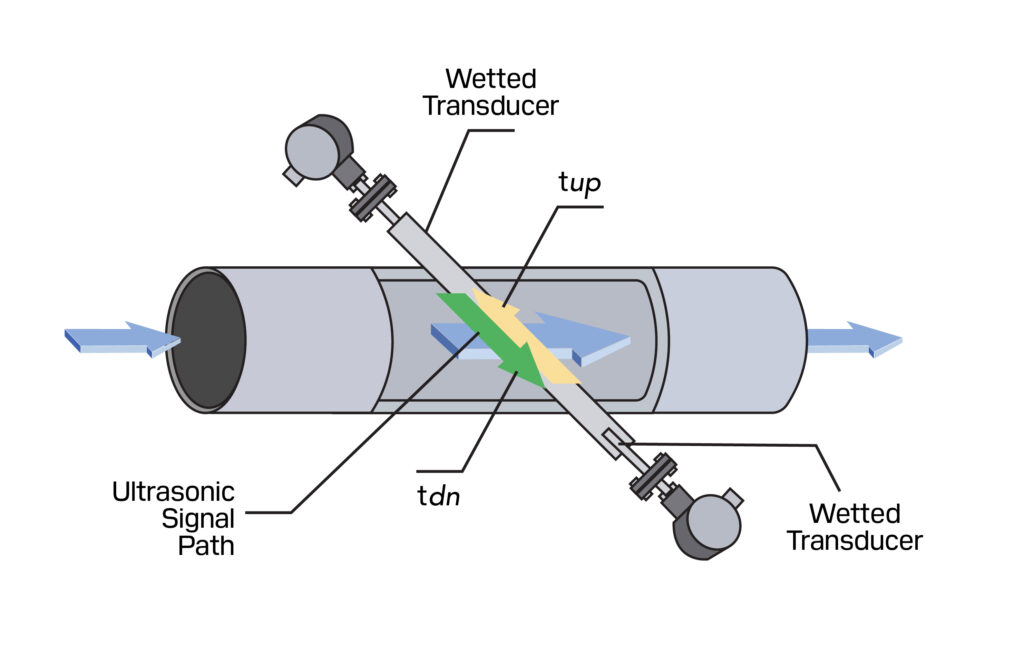

- Flow Meters – Not Suitable for Weighing Applications

Flow meters are commonly used in liquid and gas processing to measure material movement in and out of a vessel, but they cannot provide a real-time, continuous weight measurement of vessel contents.

- Only works with flowing materials – A full tank or static liquid level cannot be measured.

- Accuracy depends on flow consistency – Variations in viscosity, air pockets, and pressure changes can create errors.

- Not practical for batch processing – Cannot track multiple ingredients mixed in a single vessel.

While flow meters help monitor liquid transfer rates, they are not a substitute for direct mass measurement using load cells.

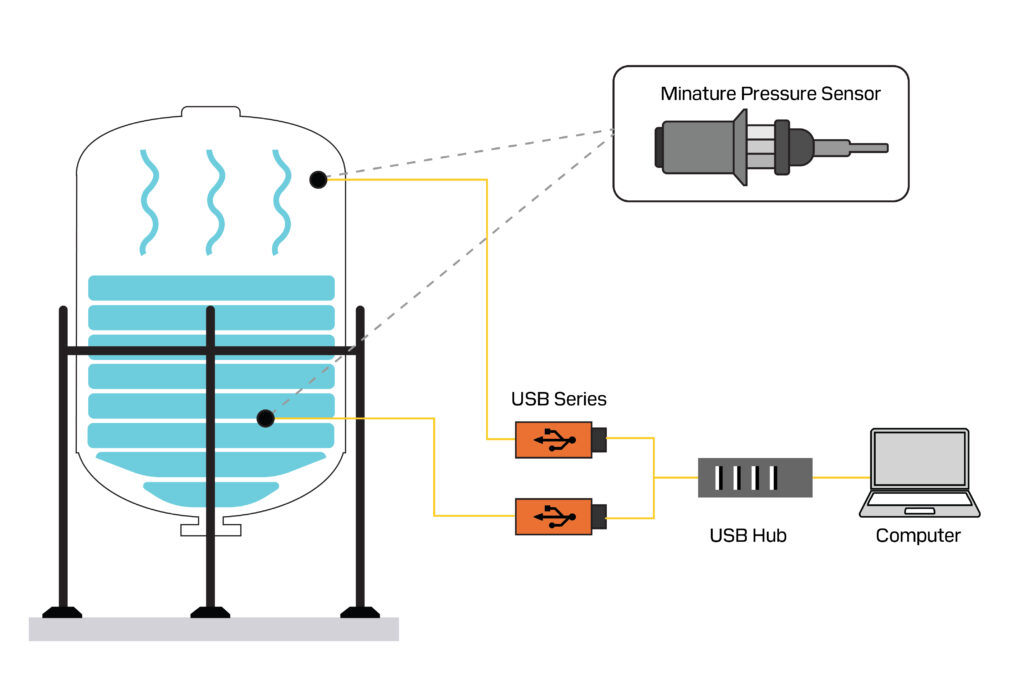

- Differential Pressure Sensors – Sensitive to Density Changes

- Density fluctuations affect readings – Material weight can change due to temperature shifts, aeration (in powders), or variations in chemical composition.

- Not ideal for solids or mixed-phase materials – Can be unreliable when measuring powders, slurries, or non-homogeneous mixtures.

- Requires contact with the material – Pressure sensors are installed inside the vessel, meaning they are exposed to corrosive, abrasive, or high-temperature materials, leading to higher maintenance needs.

For applications requiring consistent accuracy across different materials, load cells provide a more stable and versatile solution.

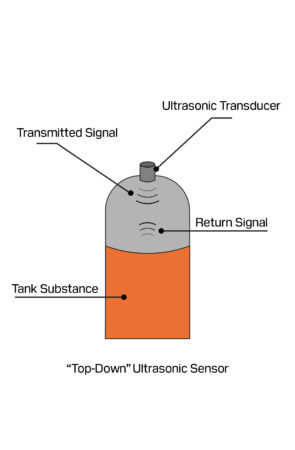

- Ultrasonic & Radar Level Sensors – Difficulties with Certain Materials

Ultrasonic and radar sensors detect material levels by bouncing sound waves or radar pulses off the surface inside the vessel. These are common for liquid and bulk material storage but have major weaknesses:

- Surface variations affect accuracy – Powders, foam, and turbulent liquid surfaces create inconsistent reflections, leading to unreliable readings.

- Environmental interference – Dust, condensation, and extreme temperatures can disrupt sensor signals, requiring frequent maintenance and re-calibration.

- Does not measure actual weight – These sensors estimate volume, not mass, meaning weight calculations depend on material density, which can fluctuate.

Compared to load cells, which measure the actual mass of the contents, ultrasonic and radar systems often require additional calibration to remain reliable.

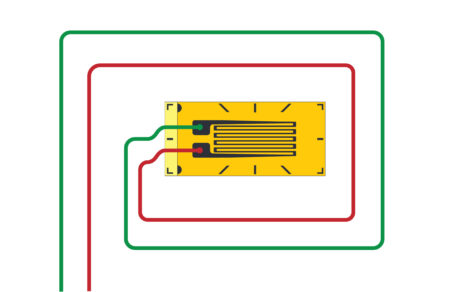

- Strain Gauges & Extensometers – Low Accuracy & High Sensitivity to Structural Changes

- Less accurate than load cells – Results can drift due to temperature changes, humidity, or material fatigue in the vessel structure.

- Highly sensitive to structural movement – External forces such as wind, seismic activity, or uneven settling of the foundation can introduce significant errors.

- Requires complex calibration – Strain gauge-based systems need careful calibration for each vessel and must be regularly adjusted over time.

Key Advantages of Load Cell Weighing Systems

Unlike alternative methods that infer weight from level, pressure, or flow, load cells measure true mass, eliminating external factors like density variations, material inconsistencies, and structural interference.

✓ No direct contact with vessel contents – Load cells are installed at the support structure rather than inside the vessel, reducing exposure to corrosive chemicals, abrasive materials, extreme temperatures, or process contamination. Load cells measure total vessel weight without direct interaction with the contents, ensuring greater reliability, lower maintenance, and superior long-term accuracy across a wide range of applications.

✓ Works with all vessel types – Load cells are used for tanks, hoppers, silos, and process vessels, regardless of contents or material type.

✓ Highly accurate and repeatable – Load cells are designed for long-term stability with minimal drift or recalibration needs.

✓ Legal-for-trade applications – Unlike many alternative methods, many load cells are NTEP/OIML certified for commercial weighing applications and many scales are trade approved in local jurisdictions.

✓ Handles dynamic forces – Load cell weighing systems can provide accurate measurements even in mixing, filling, or discharge applications, unlike flow-based or level-based systems that struggle with movement.

Conclusion: The Foundation of Effective Vessel Weighing

Vessel weighing is a fundamental component of industrial material handling and process control, ensuring precise measurements for inventory management, batching, and regulatory compliance. Whether weighing a small ingredient hopper or a multi-ton silo, the success of a weighing system depends on proper design, installation, and integration into the larger process environment.

Several key factors influence the accuracy and reliability of vessel weighing systems. The physical structure of the vessel, including leg support, mounting configurations, and surrounding infrastructure, must be designed to accommodate load cells without introducing unintended forces. External factors such as vibration, temperature fluctuations, material movement, and wind loading can also affect measurement stability and should be considered in system design. Additionally, calibration and periodic maintenance play a crucial role in ensuring long-term performance, especially in dynamic weighing environments where materials are constantly being added, mixed, or discharged.

Understanding these foundational concepts helps engineers and operators select the right technology, optimize system performance, and prevent costly measurement errors. In the next section, we will explore vessel weighing system design, focusing on load cell selection, structural integration, and best practices for maximizing accuracy and system longevity.