Guide to Truck Scale

Last Updated On July • 8 min read

Truck scales are foundational to the safe, efficient, and compliant movement of goods across virtually every sector of the economy. Whether in logistics hubs, mining operations, agricultural terminals, or industrial processing plants, these systems serve a singular but indispensable purpose: accurately determining vehicle weight. This simple function underpins regulatory compliance, transaction integrity, infrastructure protection, and operational efficiency.

- Introduction: What is a Truck Scale?

- Type of Truck Scales

- Anatomy of a Truck Scale

- Weighbridge Design and Construction

- Understanding Technical Specifications of Truck Scales

- Scale Foundations

- Installation

- System Integration

- Maintenance and Servicing

- Legal-for-Trade Applications and Road Going Weight Regulations

Introduction: What is a Truck Scale?

A truck scale, also referred to as a vehicle scale or weighbridge, is a large, heavy-duty platform designed to measure the total weight of a vehicle and its cargo. Constructed from structural steel and sometimes concrete, truck scales operate using precision load cells strategically mounted beneath the deck. These load cells detect mechanical force and convert it into accurate electronic weight measurements, enabling precise and repeatable readings across a range of applications.

Typical full-length truck scales range from 60 to 120 feet (18 to 36 meters) in length and 10 to 12 feet (3 to 4 meters) in width, with gross capacity ratings of up to 280,000 lbs (130 metric tons).

Applications:

Truck scales are widely deployed across industries where vehicle weight plays a critical role in compliance, billing, inventory tracking, or safety enforcement. Weighbridges serve as essential infrastructure in both public and private sectors.

- Highways and Enforcement Weigh Stations

Governments and transportation authorities operate permanent and mobile weigh stations to enforce road weight regulations. These legal-for-trade truck scales help prevent overloading, reduce road damage, and ensure that commercial carriers comply with axle and gross vehicle weight limits. - Concrete, Asphalt, and Bulk Batching Plants

Truck scales are a core part of daily operations at ready-mix concrete, asphalt, and aggregate processing plants. Materials are weighed both in and out to ensure batch accuracy, verify deliveries, and manage raw inventory levels. Precision and reliability are crucial, particularly in high-throughput environments where frequent scale usage occurs under heavy loads and abrasive conditions. - Logistics and Freight Terminals

At distribution centers, cross-docks, and intermodal facilities, truck scales are used to verify load compliance before shipping and to reconcile weights for billing or documentation. Accurate weight data reduces freight disputes and helps ensure that trailers are loaded evenly and safely, especially for over-the-road and international shipping operations. - Waste Management and Recycling

Waste transfer stations and recycling yards use truck scales to measure inbound and outbound material volumes for billing, landfill fee calculation, and regulatory reporting. These environments are often harsh and debris-filled, requiring rugged scale platforms and corrosion-resistant components. - Agriculture and Grain Handling

Truck scales are widely used at grain elevators, feed mills, and farms to weigh bulk commodities such as corn, soybeans, wheat, or livestock feed. Farmers and cooperatives rely on truck scales to measure yield, determine payments, and monitor harvest volumes. Seasonal use, mobile subframe setups, and integrated grain dump systems are common features in agricultural applications.

Types of Truck Scales

A truck scale, also referred to as a vehicle scale or weighbridge, is a large, heavy-duty platform designed to measure the total weight of a vehicle and its cargo. Constructed from structural steel and sometimes concrete, truck scales operate using precision load cells strategically mounted beneath the deck. These load cells detect mechanical force and convert it into accurate electronic weight measurements, enabling precise and repeatable readings across a range of applications.

Typical full-length truck scales range from 60 to 120 feet (18 to 36 meters) in length and 10 to 12 feet (3 to 4 meters) in width, with gross capacity ratings of up to 280,000 lbs (130 metric tons).

Applications:

Truck scales are widely deployed across industries where vehicle weight plays a critical role in compliance, billing, inventory tracking, or safety enforcement. Weighbridges serve as essential infrastructure in both public and private sectors.

- Highways and Enforcement Weigh Stations

Governments and transportation authorities operate permanent and mobile weigh stations to enforce road weight regulations. These legal-for-trade truck scales help prevent overloading, reduce road damage, and ensure that commercial carriers comply with axle and gross vehicle weight limits. - Concrete, Asphalt, and Bulk Batching Plants

Truck scales are a core part of daily operations at ready-mix concrete, asphalt, and aggregate processing plants. Materials are weighed both in and out to ensure batch accuracy, verify deliveries, and manage raw inventory levels. Precision and reliability are crucial, particularly in high-throughput environments where frequent scale usage occurs under heavy loads and abrasive conditions. - Logistics and Freight Terminals

At distribution centers, cross-docks, and intermodal facilities, truck scales are used to verify load compliance before shipping and to reconcile weights for billing or documentation. Accurate weight data reduces freight disputes and helps ensure that trailers are loaded evenly and safely, especially for over-the-road and international shipping operations. - Waste Management and Recycling

Waste transfer stations and recycling yards use truck scales to measure inbound and outbound material volumes for billing, landfill fee calculation, and regulatory reporting. These environments are often harsh and debris-filled, requiring rugged scale platforms and corrosion-resistant components. - Agriculture and Grain Handling

Truck scales are widely used at grain elevators, feed mills, and farms to weigh bulk commodities such as corn, soybeans, wheat, or livestock feed. Farmers and cooperatives rely on truck scales to measure yield, determine payments, and monitor harvest volumes. Seasonal use, mobile subframe setups, and integrated grain dump systems are common features in agricultural applications.

Below are the most used protocols in industrial measurement and automation:

+

+

RS-232: Simple and Time-Tested Serial Communication

RS-232 is one of the earliest serial communication standards used in weighing systems. Features- Distance: Up to 15 meters

- Speed: 9600 – 115200 bps

- Topology: Point-to-point (1:1)

- Wiring: 3 wires (TX, RX, GND)

- Connecting an indicator to a PC

- Serial printing from scales

- Calibration interface

- Easy to implement and debug

- Low cost

- One-to-one only

- Limited noise immunity

+

+

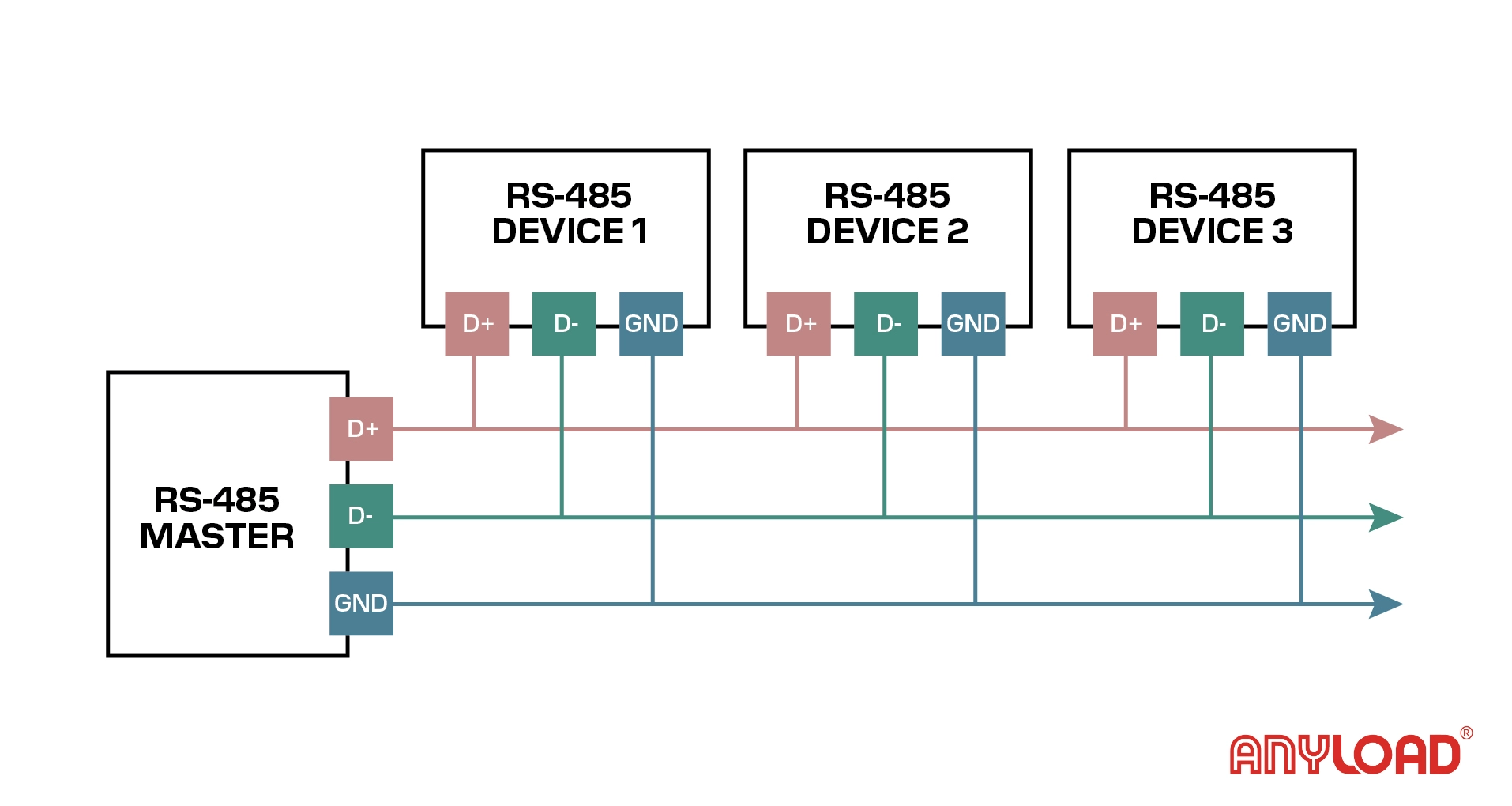

RS-485: The Industrial Workhorse for Multi-Drop Systems

RS-485 allows multiple devices to share the same two-wire communication line.

Features

- Distance: Up to 1200 meters

- Speed: Up to 10 Mbps

- Supports up to 32 devices

Use Cases

- Multi-sensor weighing systems

- Load cell junction boxes

- Long-distance installations

Pros

- High noise immunity

- Robust for harsh environments

Cons

- Requires termination and proper grounding

MODBUS RTU & TCP: A Universal Industrial Protocol

MODBUS is an application-layer protocol widely adopted in PLC and SCADA systems. It can run over RS-485 (RTU) or Ethernet (TCP/IP).

Features

- Master-slave or client-server

- Standard register-based structure

Use Cases

- Process weighing with PLCs

- Tank level monitoring

- SCADA integration

Pros

- Open standard, widely supported

- Scalable from small systems to plant-wide networks

Cons

- RTU requires strict timing

- No native device discovery

+

+

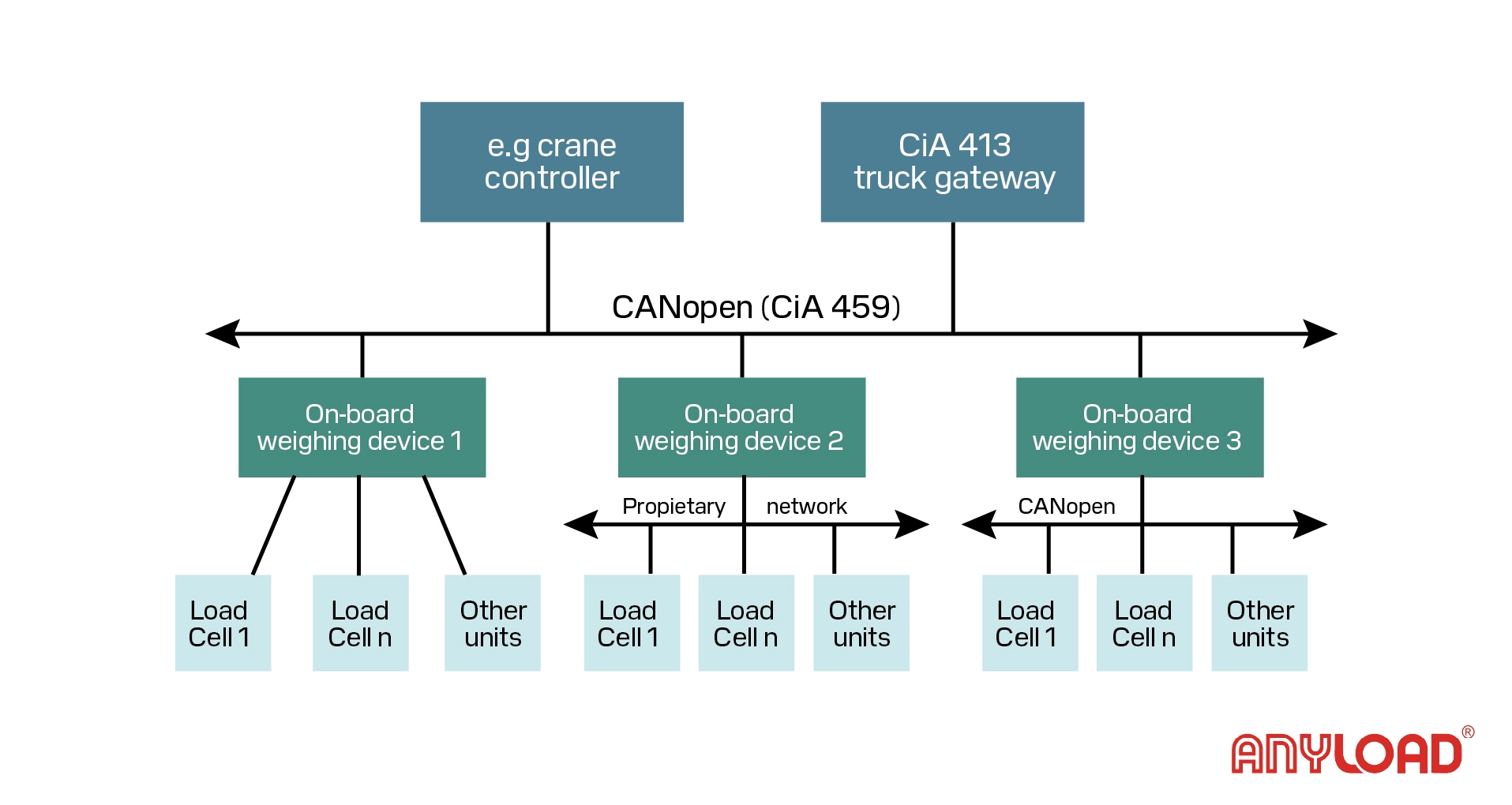

CANopen: Real-Time Precision and Full Device Control

CANopen is a real-time communication protocol designed for high-performance industrial applications.

Why CANopen Stands Out

- PDOs (Process Data Objects) for fast data

- SDOs (Service Data Objects) for configuration and diagnostics

- Based on CiA 404 standard for weighing devices

Key Benefits

- Fast updates and low latency

- Deterministic communication

- Built-in device discovery

- Supports advanced calibration and diagnostics

Use Cases

- High-speed force measurement

- Modular weighing solutions

- OEM weighing systems

Cons

- RTU requires strict timing

- No native device discovery

Ethernet (TCP/IP): High-Speed Industrial Connectivity

Ethernet brings networking to the world of weighing with standard IP protocols.

Features

- Speed: 100 Mbps to 1 Gbps

- Integration with IT/OT networks

- Supports MODBUS TCP, FTP, HTTP

Use Cases

- Remote scale monitoring

- Cloud-connected indicators

- Web-based diagnostics

Pros

- Long-distance and high-speed

- Easily integrates with industrial PCs

Cons

- Requires more power

- More expensive hardware

Wireless (Bluetooth, Wi-Fi & Cellular): Flexible, Cable-Free Integration

Wireless protocols improve mobility and simplify installation, but each has trade-offs in range, reliability, and infrastructure needs.

Bluetooth

Ideal for handheld indicators or mobile apps with short-range connections.

✔ Simple setup for local use

✖ Limited range and potential interference in industrial environments

Wi-Fi

Supports wireless weight transmission, local network integration, or cloud logging.

✔ Good for in-plant monitoring and data access

✖ Requires stable network infrastructure and security management

Cellular (3G/4G/LTE)

Used in remote or mobile weighing setups without fixed connectivity.

✔ Enables long-range communication for isolated or mobile systems

✖ Dependent on coverage area and data plan costs

+

+

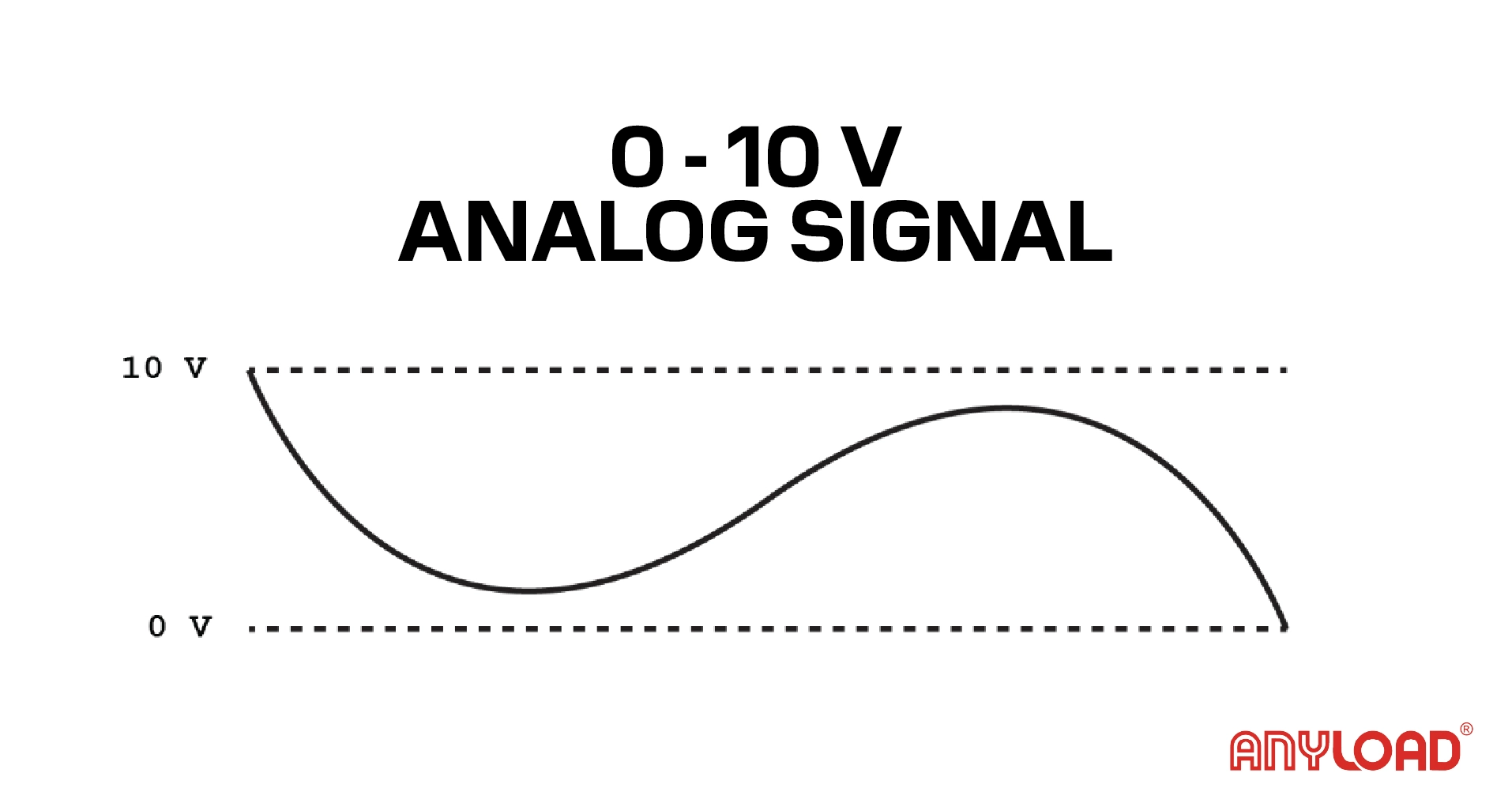

Analog Output (0–10V, 4–20mA): Simple and PLC-Compatible

Analog outputs remain in use for compatibility with legacy PLC systems and signal conditioners.

Use Cases

- Feedback loops

- Redundant analog backup

- Analog-only PLC inputs

Comparison Table of Communication Protocols in Weighing Systems

| Protocol | Distance | Speed | Devices | Best Use Case |

|---|---|---|---|---|

| RS-232 | Short | Low | 1 | Calibration & simple data output |

| RS-485 | Long | Medium | 32+ | Multi-sensor wired systems |

| MODBUS RTU | Long | Medium | Many | PLC/SCADA integration |

| CANopen | Medium | High | Many | Smart modular weighing networks |

| Ethernet | Very Long | Very High | Many | Cloud or remote access |

| Bluetooth | Short | Medium | Few | Mobile diagnostics or field apps |

| Wi-Fi | Long | High | Many | Wireless industrial connectivity |

| Analog | Long | N/A | 1 | Legacy PLC or signal replication |

Final Thoughts: Choosing the Best Communication Protocol for Your Weighing System

Each protocol brings a balance of cost, complexity, distance, and performance. For scalable, real-time, and intelligent weighing solutions, CANopen stands out with its built-in object dictionary, robust diagnostics, and industry-standard CiA 404 profile.

When selecting a protocol:

- Match it to your data rate and latency needs

- Consider integration with PLCs, cloud, or SCADA

- Think about system expansion or modularity

ANYLOAD Products with Communication Protocol Support

ANYLOAD offers a range of devices designed to allow load cells (and all Wheatstone-bridge-based sensors) to interface with modern control systems using industry-standard communication protocols:

- Digital Amplifier Boards (DGB Series): Compact signal conditioners that support RS-485 (Modbus RTU), RS-232, CANopen, and analog (mV/V or 4–20 mA) outputs. Ideal for retrofitting analog load cells into digital systems or integrating with PLCs and DAQs.

- ACT1 Transmitter Series: A versatile field-mount transmitter available with Modbus RTU, Modbus TCP (Ethernet), CANopen, analog, PROFINET, PROFIBUS, and other output options. Designed for industrial and outdoor environments, the ACT1 enables direct connection between load cells and automation or monitoring systems.

- AN310 Panel-Mount Indicator: A multifunctional weighing display with support for RS-232, RS-485, Modbus RTU, Ethernet TCP/IP, and analog output. Suitable for control panel integration in batching, filling, and general industrial applications.

These products help bridge the gap between precision load cell measurements and broader system controls, ensuring seamless data flow in wired or wireless setups.

Need Help Choosing the Right Protocol?

We specialize in load cell integration, digital amplifier communications, and custom protocol configurations for industrial weighing applications.

Contact us today to build a smarter, more connected weighing system.