Grain & Bulk Material Handling

Weighing for Silos, Hoppers, Batching & Transfer

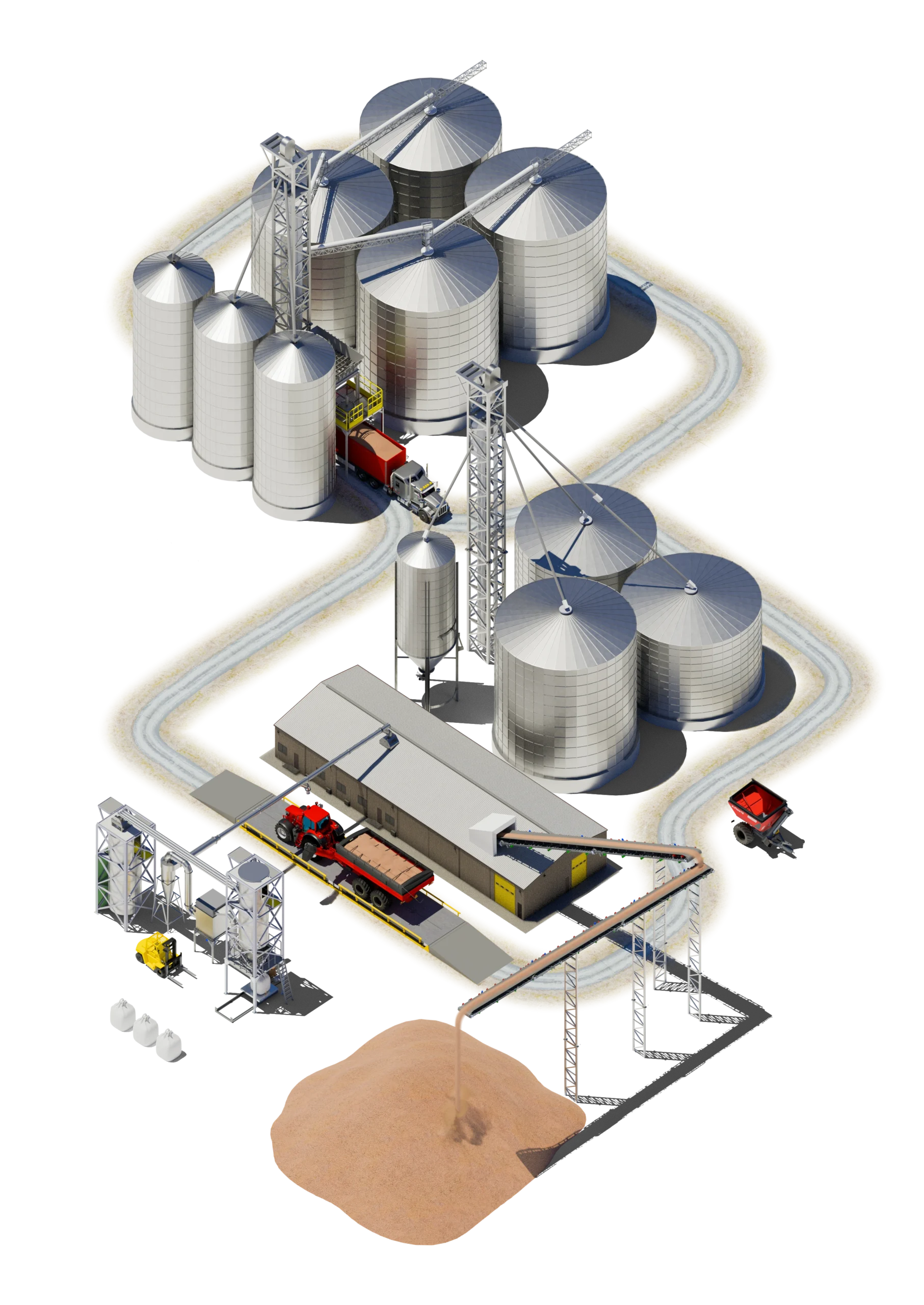

Precise weight measurement is essential across all stages of grain and bulk material handling—from storage and blending to loadout and transport. ANYLOAD supplies high-capacity, industrial-grade load cells for silos, grain bins, hoppers, bulkweighers, and conveyor or chute systems. Our solutions support legal-for-trade compliance (NTEP/OIML, etc.), real-time monitoring, and seamless integration with batching controllers and SCADA systems.

Whether managing inventory, automating transfer sequences, or dosing ingredients for animal feed or crop inputs, ANYLOAD sensors provide the reliable weight data needed for efficient, safe, and scalable grain handling.

Applications Include:

- Silo & Bin Weighing Systems: Install weighing systems beneath silos or grain bins to monitor real-time inventory levels with legal-for-trade accuracy.

- Hopper & Ingredient Batching: Manage granular or powdered ingredient flow in batching control, loss-in-weight systems, and bulk bag filling or unloading.

- Bulk Transfer & Logistics: Bulkweighers, in-motion conveyors, and truck scales enable automated loadout, intake, and transfer operations.

- Hazardous Environments : ANYLOAD offers ATEX, IECEx, and FM-approved intrinsically safe load cells for use in dust-prone or combustible environments, such as grain silos or fertilizer blending lines, ensuring compliance with safety standards.

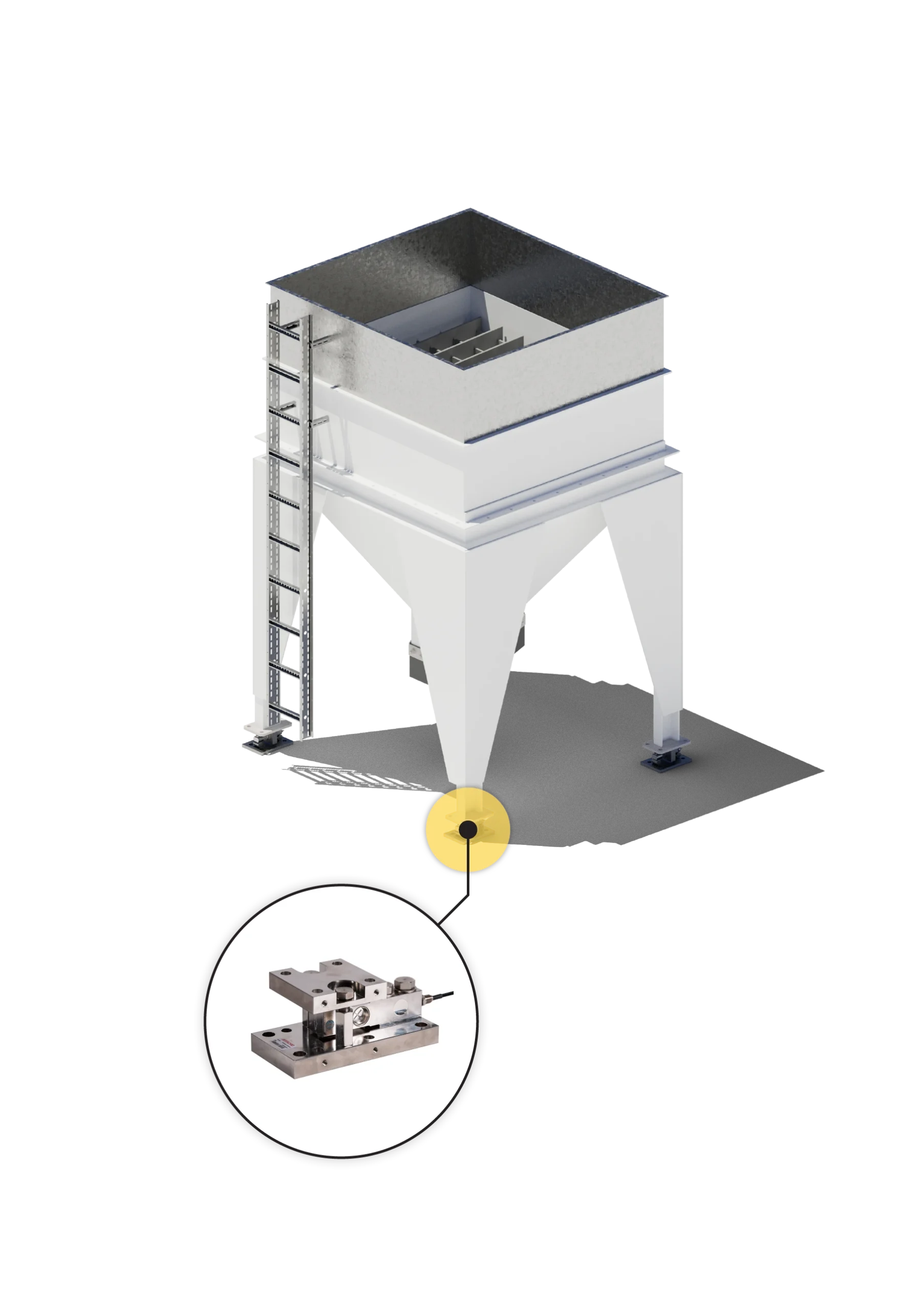

Silo & Bin Weighing

Weighing silos and grain bins is essential for maintaining accurate inventory records, managing throughput, and optimizing supply chain decisions. ANYLOAD supplies high-capacity load cells and mounting assemblies specifically designed for fixed vessels, supporting everything from farm-level storage to commercial grain terminals.

Challenges & Solutions

- Uplift & Sideload Protection: Silos are subject to lateral forces from wind gusts, thermal expansion, or seismic events. ANYLOAD load cells with self-aligning mounts maintain performance under off-axis loading.

- Foundation Shifts & Structural Settling: Uneven ground settling or installation misalignment can skew weight distribution across support legs, requiring mounting assemblies are engineered to compensate for shifts in structural balance.

- Harsh Environmental Exposure: Outdoor and unconditioned environments expose equipment to temperature swings, moisture, and dust. ANYLOAD load cells are IP-rated, hermetically sealed, and available in coated or stainless steel options to perform reliably year-round.

- Legal-for-Trade Compliance: For commercial operations, certified accuracy is a must. ANYLOAD offers NTEP and OIML-certified load cells to meet regulatory requirements for trade.

To Learn More:

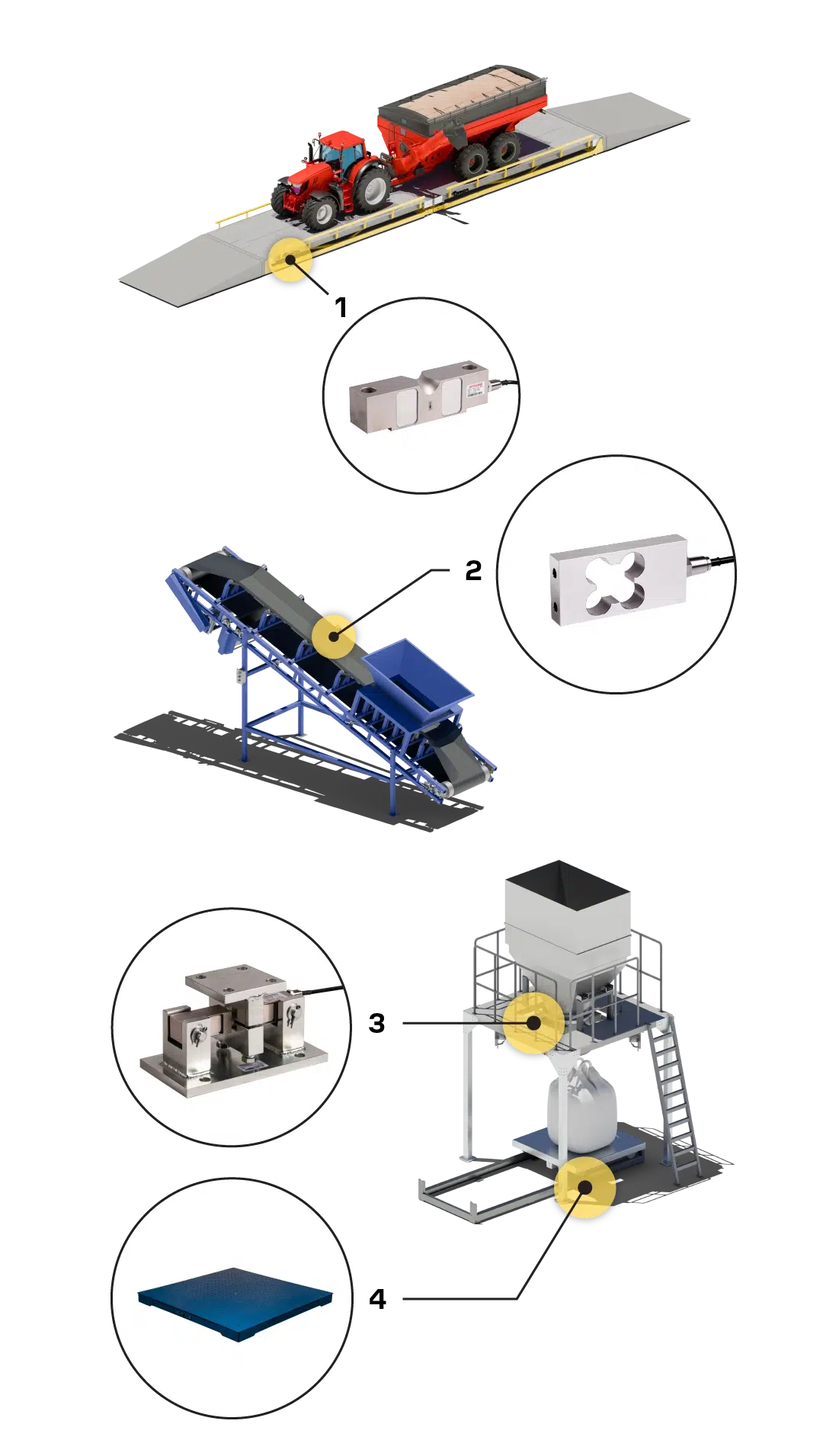

Hoppers & Batching

Hopper and batching systems rely on accurate weight measurement to control material flow, automate ingredient blending, and maintain consistency in feed mills, seed plants, and fertilizer facilities. ANYLOAD supplies shear beam, S-type, and single-point load cells engineered for both suspended and platform-mounted hoppers, delivering precise, repeatable performance even under fluctuating load conditions.

From bulk bag unloading to micro-ingredient dosing, our sensors support both manual and fully automated systems, with seamless integration into PLCs, batching controllers, and supervisory systems.

Challenges & Solutions

- Dynamic Loading: Material flow during fill and discharge causes shifting loads, surges, and vibration. ANYLOAD load cells are fatigue- and overload-rated, with fast response times that ensure accurate readings during rapid filling or pulsed discharge cycles.

- Mechanical Constraints: Batching hoppers may be floor-mounted, frame-supported, or suspended. ANYLOAD offers a wide range of tension and compression weighing options with mounting kits to simplify integration in tight spaces or multi-point systems.

- Process Control Compatibility: Batching accuracy depends on tight integration with control systems. ANYLOAD solutions support analog (4–20 mA, 0–10 V) and digital (RS485, Modbus, CAN bus) outputs for real-time feedback and closed-loop control.

- Cleanability & Corrosion Resistance: Exposure to feed dust, moisture, and aggressive additives can degrade components over time and introduce contamination. ANYLOAD offers load cells with sealed housings, chemical-resistant coatings, and IP-rated protection to ensure long-term reliability.

To Learn More:

Bulk Transfer & Logistics

Bulkweighers, in-motion conveyors, and truck scales are essential components of grain handling and logistics operations. From loadout stations to intake points, ANYLOAD provides high-capacity compression and shear beam load cells engineered for dynamic weighing, gross and net weight verification, and legal-for-trade compliance.

Whether batching by mass, reconciling deliveries, or automating scale house operations, ANYLOAD solutions are built for accuracy, speed, and durability in rugged agricultural environments.

Challenges & Solutions

- Vehicle Load Verification: Truck and rail scales require certified accuracy to meet trade and regulatory standards.

- Data Integration: Grain handling operations often require central data collection and remote monitoring. ANYLOAD products support analog and digital outputs for integration into SCADA systems, batching controllers, or scale terminals.

- Harsh Environments: Weighing systems are subject to continuous mechanical stress, debris, and weather exposure. Our sensors are fatigue-rated, IP-rated, and available in stainless steel or coated options for year-round outdoor use.

To Learn More:

Hazardous Environments

Agricultural processing facilities often present explosive atmospheres due to combustible dust from grain, seed, or fertilizer. ANYLOAD provides ATEX, IECEx, and FM-certified load cells engineered for safe use in Zone 1/ Division 1 areas, ensuring reliable force measurement while complying with international safety regulations.

Challenges & Solutions

- Combustible Dust & Hazardous Zones: Dust from grain or organic materials can ignite under the right conditions. ANYLOAD offers load cells rated for use in hazardous environments, including dust and gas zones, with certifications to meet ATEX (EU), IECEx (global), and FM (North America) standards.

- Toughness & Reliability: Hazardous areas often overlap with harsh operating conditions. ANYLOAD sensors are built to survive in the most challenging environments to ensure minimal servicing.

- Compliance & Documentation: Meeting safety standards requires traceability and documentation. ANYLOAD provides full certification packages, including datasheets, zone classification details, and support for OEM integration and facility safety audits.

View Products: