Vacuum-Resistant Sensors for Semiconductor Industry

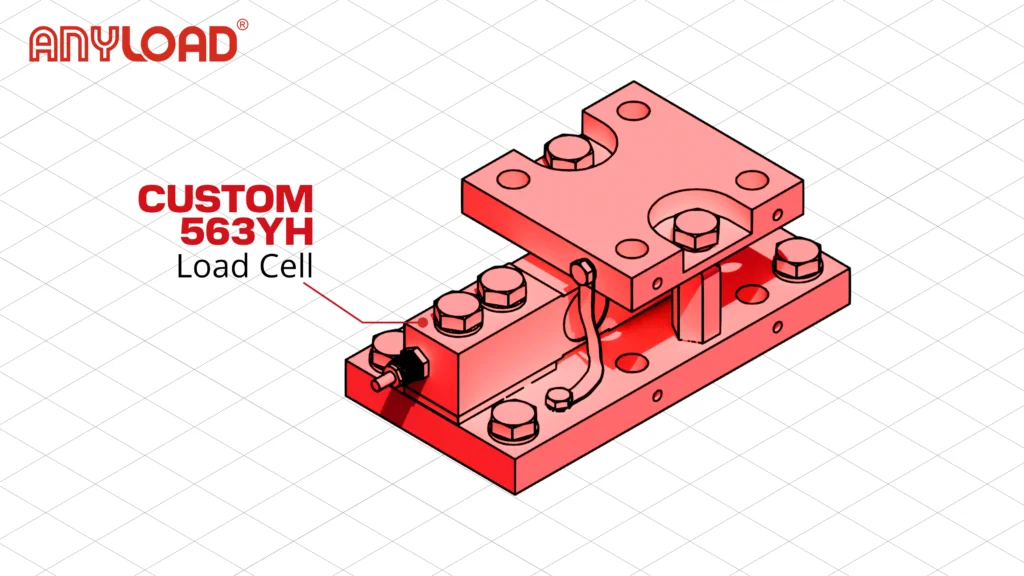

Custom Single Ended Shear Beam

Wafer growing is one of the core processes in the foundation of a high-quality semiconductor production. These high precision procedures demand strict environmental condition control for temperature, humidity, and ambient pressure. The entire procedure is conducted in a vacuum to ensure wafer purity while precisely controlling material addition by weight to guarantee continuous and stable growth. Any fluctuation in the vacuum environment or inaccuracies in weighing directly results in lower wafer purity and instability, reducing the performance yield of the final chips. Using custom ANYLOAD load cells designed for operation in a strong vacuum environment, material dosing remains accurate, reliably producing higher performing wafers.

Challenge

- Air Bubbles During Assembly: Traditional strain gauge bonding techniques often leave microscopic bubbles. In strong vacuum environments, these pressure differentials will cause the bubbles to expand, changing the strain gauge reading or damaging the sensor.

- Wire Impedance Drift: Conventional wires release volatile substances in a vacuum (known as “outgassing”) which affects wire impedance, signal transmission, and the overall precision of the load cell.

- Seal Expansion: Regular sealing methods can expand in vacuum environments, exposing the strain gauges to moisture and other elements. Seal expansion can also release contaminants, polluting the wafer growth environment.

- Unstable Compensation Performance: The impedance of an ordinary sensor varies significantly between atmospheric and vacuum environments, creating deviations in sensor output and unreliable weighing results.

Solution

- A custom vacuum-resistant load cell is developed specifically for the customer’s wafer growth process, carefully addressing each challenge the environment presents.

- A proprietary bonding technique is paired with high-precision fixtures to ensure strain gauges and other elements achieve perfect adhesion without the addition of micro-bubbles, safeguarding data accuracy even under extreme vacuum

- High-performance vacuum-resistant wires replace standard load cell conductors, with both ends hermetically sealed to prevent noticeable pressure changes inside the load cell.

- All sealing materials undergo pre-treatment within vacuum chambers to fully eliminate outgassing and ensure the specially formulated adhesive does not change behaviour under vacuum conditions, maintaining the strain gauge’s moisture resistance and integrity.

- Special vacuum-resistant compensation resistors are used in the load cell’s construction so that there is minimal impedance variation between atmospheric and vacuum conditions, ensuring industry-leading accuracy and performance.

Conclusion

ANYLOAD has developed and selected its own materials and technologies for vacuum environment applications. Production processes have been specially optimized for these strict environments, with certain steps being completed under vacuum conditions, ensuring the sensor maintains superior performance in critical settings.

Field testing confirms the sensors can operate reliably in pressure as low as 1 Pa, allowing broad use in aerospace manufacturing, pharmaceutical material weight control, solar photovoltaic panels, and others. For industries with stringent requirements for vacuum operation and accuracy, ANYLOAD vacuum-resistant sensors enhance production efficiency, product quality, reduce costs, and provide reliable weighing for advanced manufacturing.

Featured Products

563YX-AS-VAC

Single Ended Beam Load Cell

See standard version.

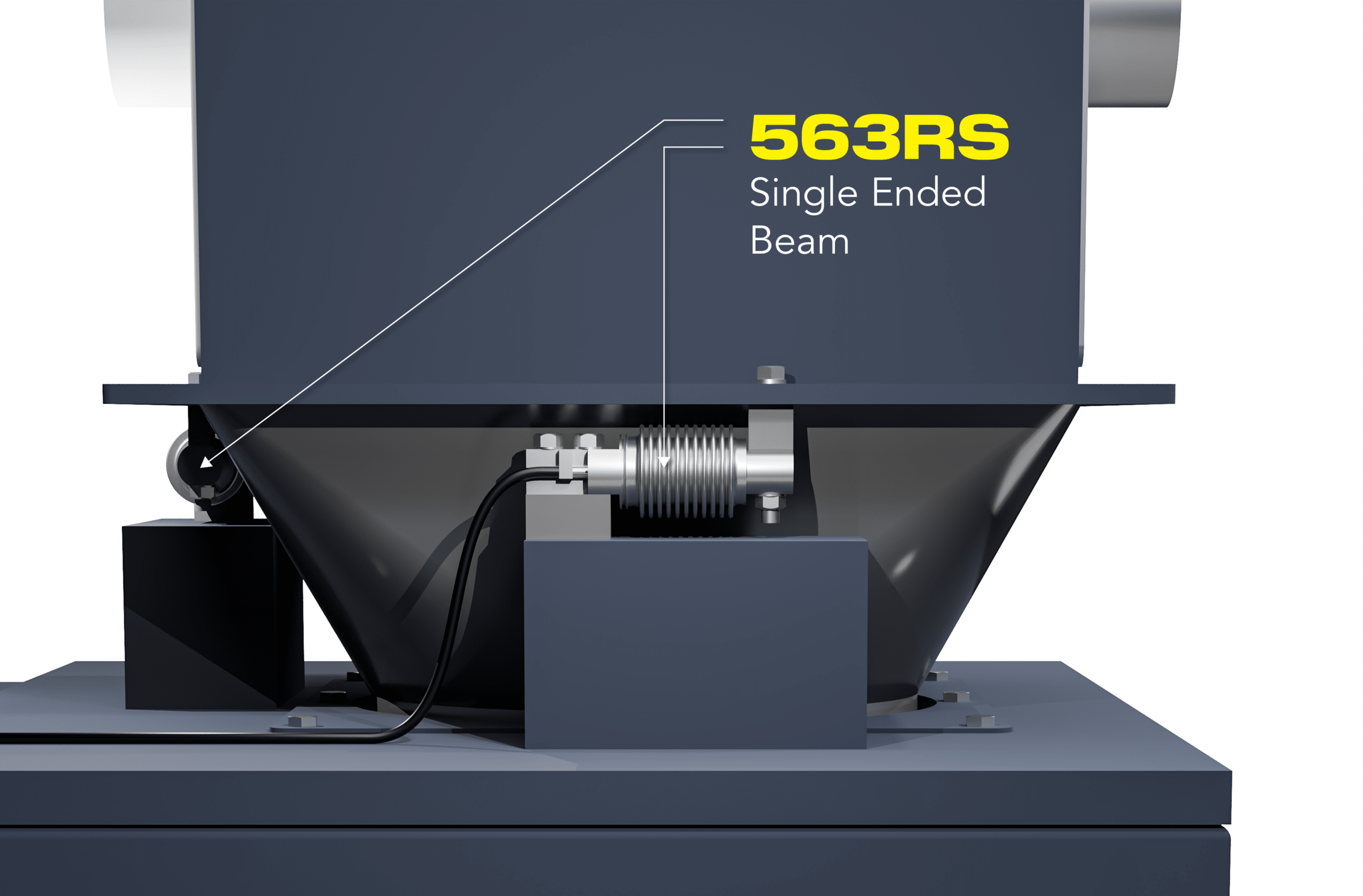

High-Temperature and Vacuum Shear Beam Load Cells from ANYLOAD are designed for environments where standard sensors fall short. Built for aerospace, semiconductor manufacturing, metallurgy, and advanced research, they provide the accuracy and stability needed under extreme thermal and pressure conditions, while offering the flexibility to be configured for unique project requirements.

- Applications: aerospace, semiconductor manufacturing, metallurgy, advanced research, etc.

- Special configuration based on the proven 563YH load cell platform, engineered for demanding vacuum and high-temperature applications

- Vacuum-compatible (option): Sealed internal cavities and low-outgassing construction for dynamic vacuum environments down to 1 Pa (~1 x 10-² Torr)*, rated for repeated vacuum cycling.

- High Temperature Resistance (option): Compensated range* -10°C to 150°C, operational up to 200°C

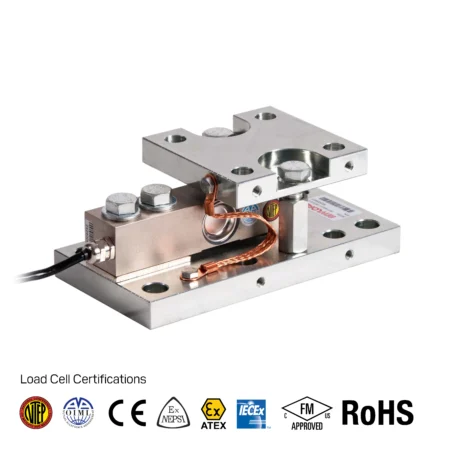

563YHM4-02

Compression Weigh Module

See standard version.

- Assembles: 563YH Alloy Steel Shear Beam Load Cell

- Capacities: 100lb-20Klb/100kg-10t

- Integral “Jacking” for easy load cell removal/installation

- Rocker pin design-allows for 360° thermal expansion

- Both uplift and overload protection with lateral stops

- Versatile mounting options for conventional tank/vessel leg

- Able to use existing 4-square tank leg mount holes in floor

- Free to rotate for fixed position 360° w/same 4-mount holes

- Able to flip entire mount 180° for further mount options

- Side holes each side for shipping & installation brackets

- Flexible copper braided grounding strap

- Load cell not included

815BS

Weight Indicator

See standard version.

- 1.0″ 6-digit, 7-segment LCD display with tri-color backlight

- Supports kg, lb, oz, g

- Gross / net / tare indicators; stability and center-zero

- Easy screw-terminal wiring

- Weight, peak, setpoint, and piece-count modes

- Password-protected setup and calibration with audit trail

- Advanced analog, averaging, and digital filtering

- Dual RS232 ports

- UL-approved wall adapter

- Built-in lithium battery and charger

Agricultural Weighing Solutions

How agricultural industry uses our load cell for cart and mobile equipment for optimal result

Increase Turbine Life Span

Gravimetric quality assurance solution for wind turbine blades studies

Bag Filling Machine Load Cells

Bag filling and other process weighing and control system for maximal efficiency