Road Line Painting Vehicle

Mobile Paint Drum Weighing for Road Line Striping Equipment

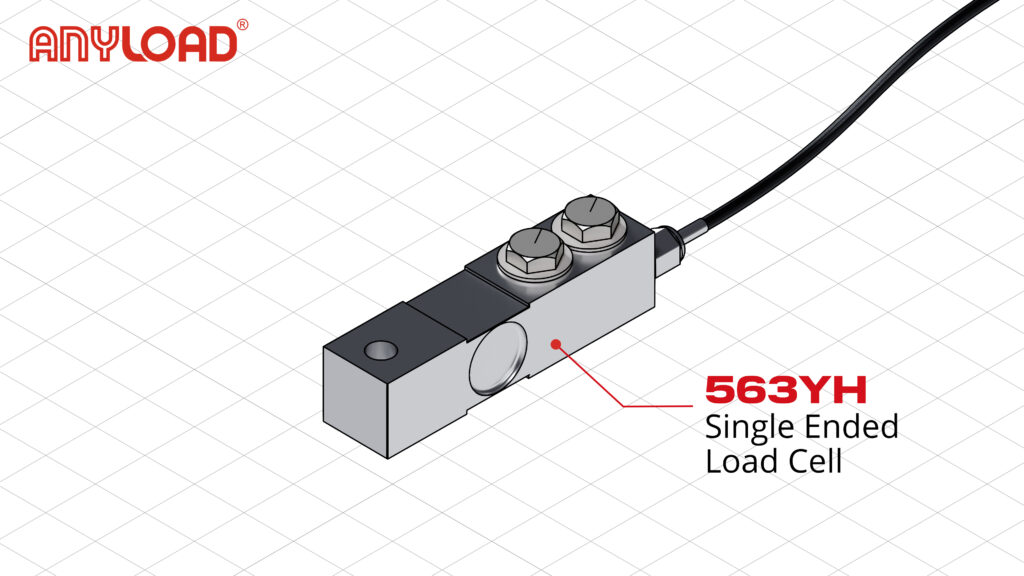

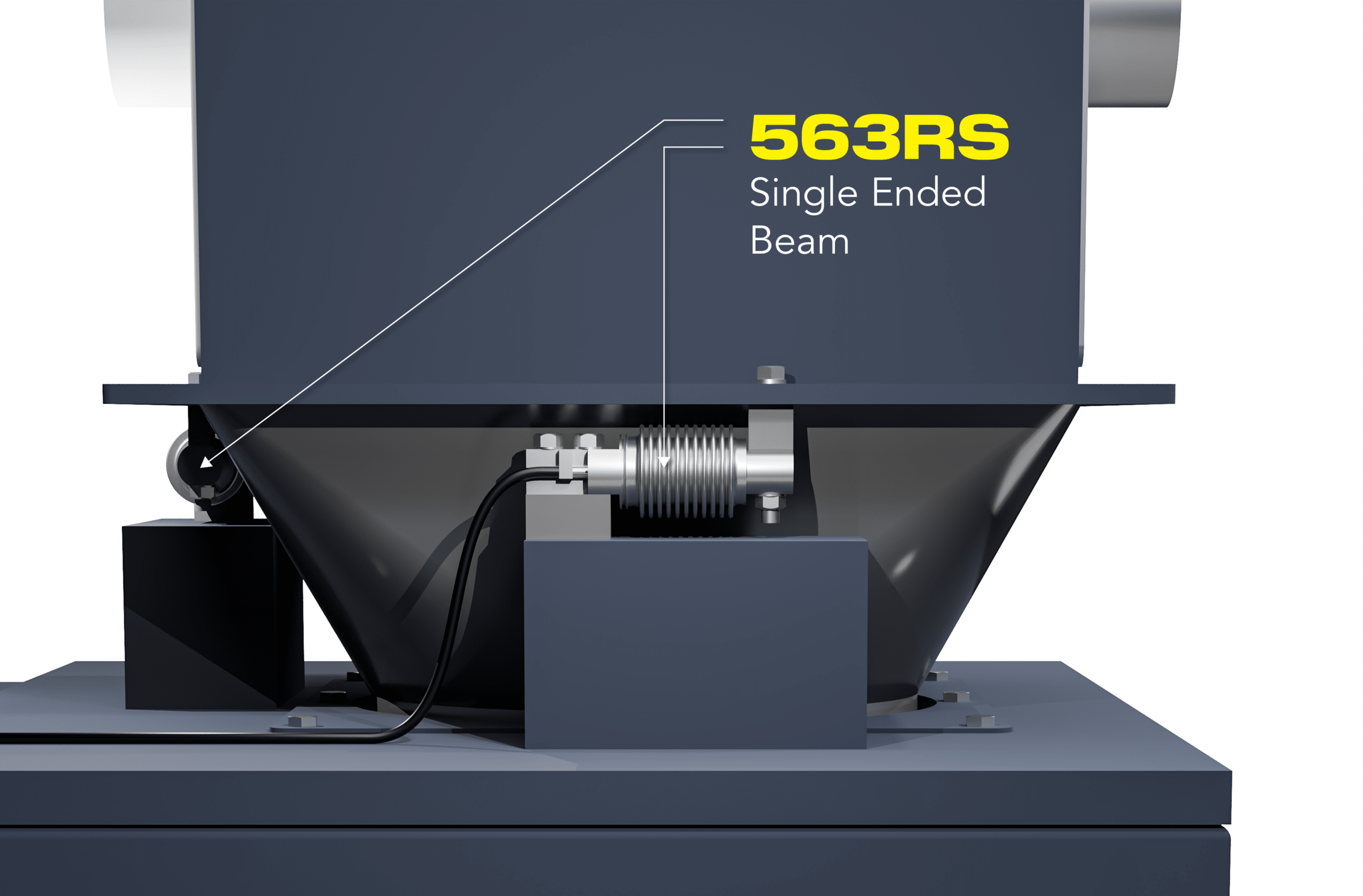

Line painting vehicles play a vital role in maintaining traffic safety with consistent markings across roads and highways. Monitoring paint usage is critical to ensure consistent line density during operations, especially in a dynamic environment. To address this, ANYLOAD 563YH single ended shear beam load cells are integrated into the mobile paint striper to track the live weight of the mounted paint drum during operation.

Challenge

- Weight Monitoring in Motion: The system needs to continuously monitor paint volume while the vehicle is in motion, requiring a stiff and high accuracy setup to record stable weight data without vibrations and shifting loads.

- Low-Profile, Outdoor Mounting: The load cell must fit within a small area underneath the paint drum without affecting the operation of the system (i.e. notably increasing the vehicle’s center of gravity). The sensor must also be able to perform reliably in outdoor environments with exposure to water, temperature swings, chemical overspray, and road debris.

- High Linearity: The tank’s weight must remain accurate at all fill volumes as the paint container will frequently be drained and filled, requiring the load cell to maintain precision throughout the whole measurement range.

Solution

1. The 563YH single ended shear beam load cell was chosen for its compact form factor, high resistance to off-axis and side loading, and stiffness, ideal for mobile use and installations in demanding and dynamic conditions.

2. The load cell provides continuous real-time weight data with minimal structural changes to the vehicle by mounting directly beneath the paint drum platform.

3. The IP67 or higher environmental rating ensures the sensor will operate reliably while withstanding road spray and debris during painting.

4. The load cell is calibrated for the full weight range of the drum, ensuring accurate monitoring as the paint level decreases throughout the jobs performed.

5. Integrated signal output allows the driver to see the paint levels in real time and plan refills without major workflow interruptions.

Conclusion

The integration of the 563YH single-ended shear beam load cell enables real-time monitoring of the paint usage in Core Equipment’s road line painting vehicle, reducing downtime from unexpected refills and ensuring consistently laid road lines, crucial for driver safety. The compact and durable design make it ideal for dynamic, mobile applications such as on top of a vehicle. For more information on sensors and custom applications, please contact ANYLOAD.

Featured Products

563YH-23

Single Ended Load Cell

See standard version.

- Material: Alloy Steel

- Rated Capacities: 250lb, 500lb, 750lb, 1Klb, 1.5Klb, 2Klb, 2.5Klb, 4Klb, SE5Klb, 5Klb, 10Klb, 15Klb, 20Klb

- CE, RoHS, and Ex certified

Cost-effective and heavy-duty, the 563YH-23 is a single-ended beam load cell. Its low-profile design with IP67 water resistance and high resistance to overload and shock and side loading. This model is popular in higher accuracy applications, including platform scales, pallet scales, process weighing, and more.

Agricultural Weighing Solutions

How agricultural industry uses our load cell for cart and mobile equipment for optimal result

Increase Turbine Life Span

Gravimetric quality assurance solution for wind turbine blades studies

Bag Filling Machine Load Cells

Bag filling and other process weighing and control system for maximal efficiency