CAN J1939 Load Cells for Air Seeder Testing

Digital Data Capture for Real-Time Material Distribution Analysis

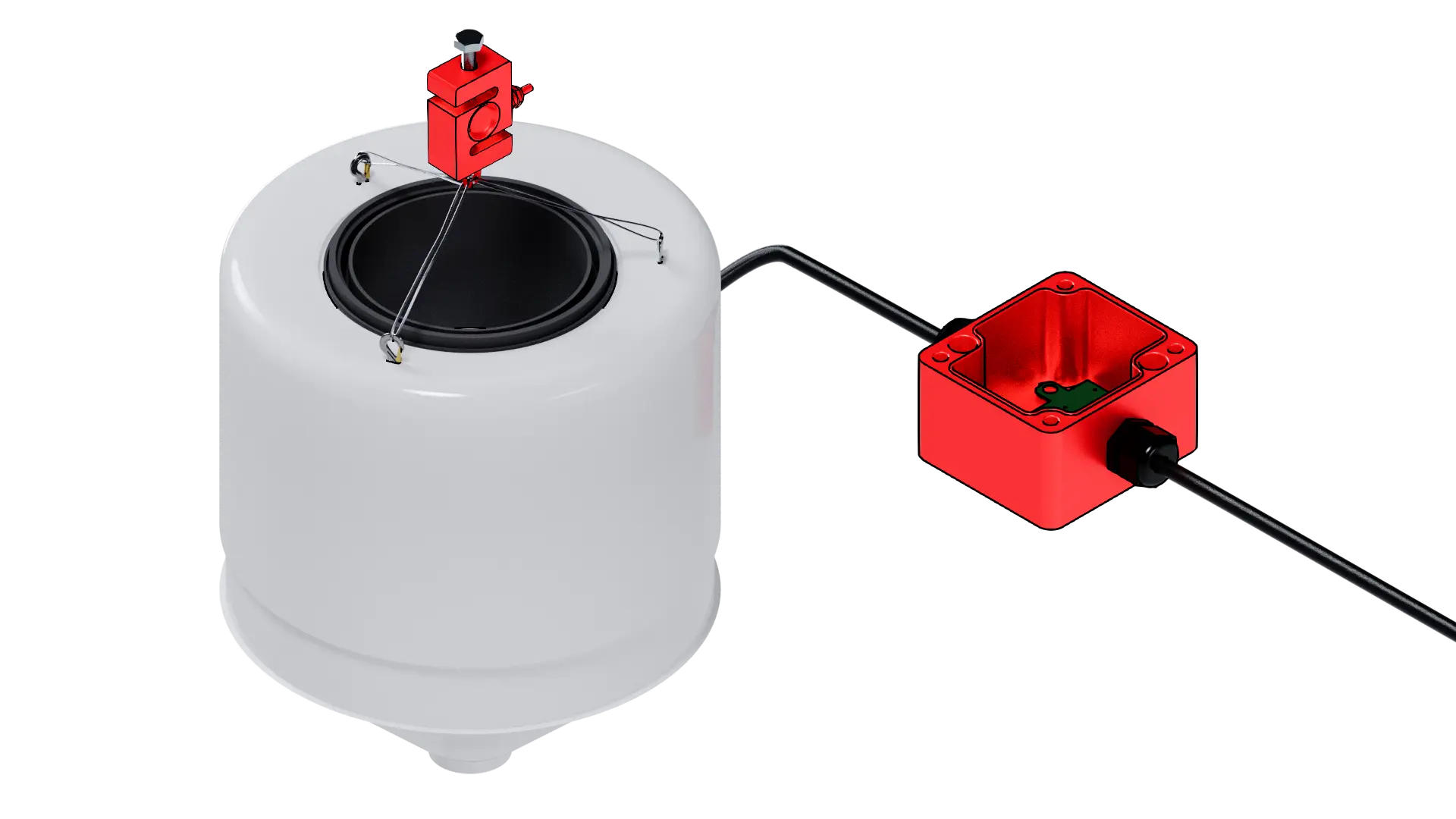

A research team set out to understand how material moves through an air-based distribution system to improve the performance of agricultural air seeders. To achieve this, a test stand was built that collects product in multiple containers and measures how much ends up in each one. Traditionally, these measurements are difficult and labour-intensive to obtain, so utilizing load cells is key to making this research more efficient. ANYLOAD’s force measurement load cells combined with CAN J1939 digital amplifiers are well suited to this agricultural application.

Challenge

- System Integration: Most load cells output analog signals that require individual analog-to-digital conversion, making multi-sensor setups complicated and time consuming.

- Scalability: As the test stand expands, adding more analog load cells can quickly become complicated, time-consuming, and costly.

- Agricultural Robustness: Agricultural testing creates challenging electrical conditions: long cable runs, vibration, dust, and multiple devices sharing the same network can all introduce interference and data instability in traditional measurement systems.

Solution

Digital Output: ANYLOAD’s load cells with CAN J1939 digital amplifiers deliver clean, digital signals that can be read directly by the test system.

Easy Expansion: Multiple load cells can be connected in one straightforward network, making the entire system easy to scale.

CAN J1939 Stability: The J1939 protocol is widely used in the agricultural industry as it was originally built for heavy-duty vehicles and machinery. Its error-checking, message prioritization, and fault-tolerant design ensure reliable weight data, even on busy agricultural networks.

Conclusion

By combining ANYLOAD’s high-performance load cells with CAN J1939 digital amplifiers, the research team gained a measurement system that is easier to integrate, simpler to scale, and far more reliable in demanding agricultural environments. Whether installed internally within the load cell for a compact and ready-to-deploy solution or used as an external module during early testing and system development, the amplifier provides exceptional flexibility for both prototype and production setups. Overall, this approach ensures clean, reliable, and real-time data, giving researchers a clearer view of material distribution and helping growers fine-tune air seeder performance.

Keywords:

A1A-DC2508-J1939C, CAN J1939, Agriculture, Air Seeder, Digital Load Cell, Real-Time Data

Featured Products

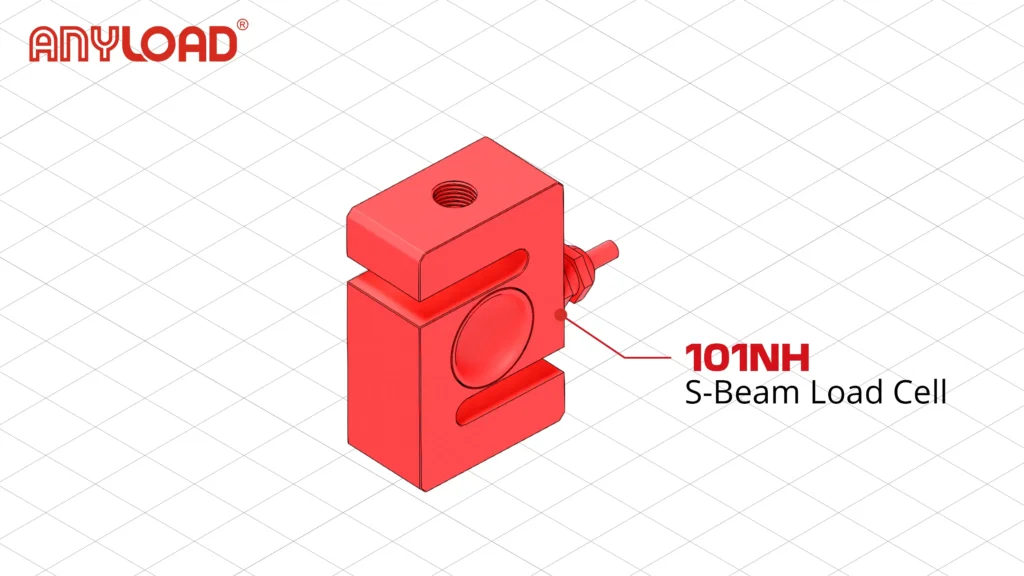

101NH

S-Beam Load Cell

See standard version.

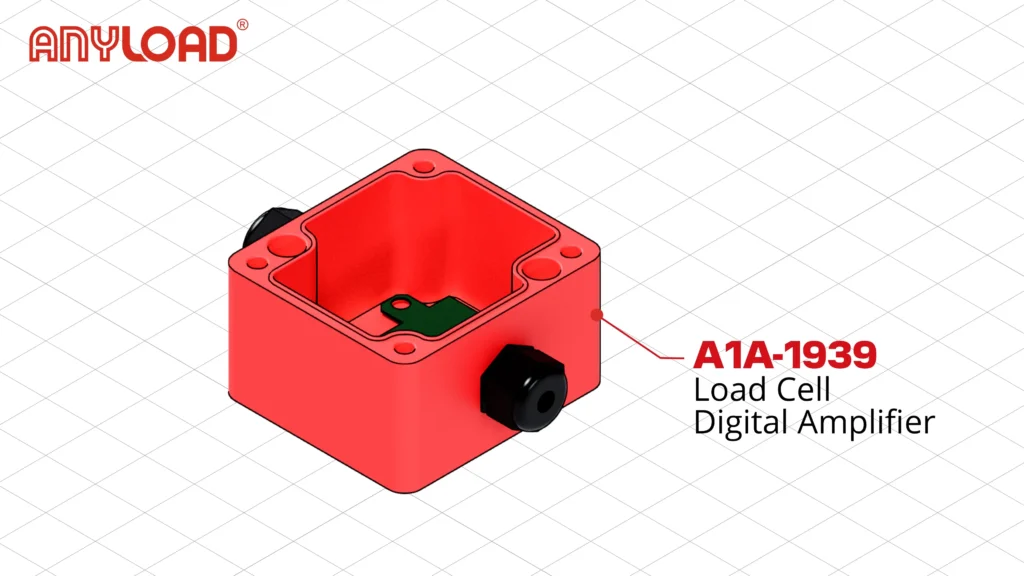

A1A-D25C

Load Cell Digital Amplifier

See standard version.

ANYLOAD A1A-D25C strain gage amplifiers provide load cell and transducer signal conditioning. The A1A-D25C series strain gage amplifiers are DC-powered amplifiers that can drive 1 load cell connected directly. They can also drive several load cells up to 4 x 350Ω load cells or 8 X 700Ω load cells through a junction box. Housed in an aluminum casting enclosure. The A1A-D25 digitizer module includes both RS232 and RS485 communication interfaces with ModBus protocol.

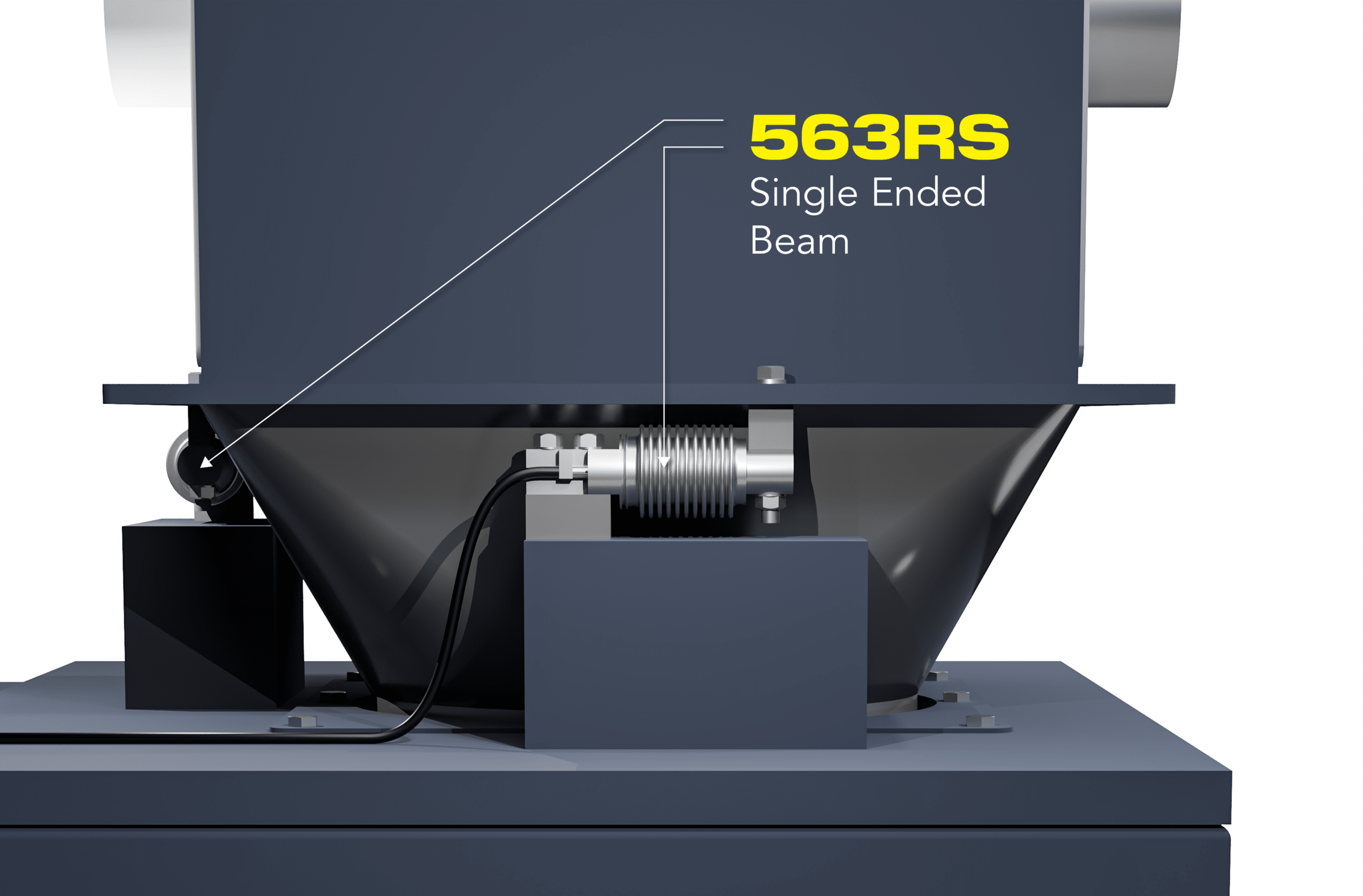

Agricultural Weighing Solutions

How agricultural industry uses our load cell for cart and mobile equipment for optimal result

Increase Turbine Life Span

Gravimetric quality assurance solution for wind turbine blades studies

Bag Filling Machine Load Cells

Bag filling and other process weighing and control system for maximal efficiency