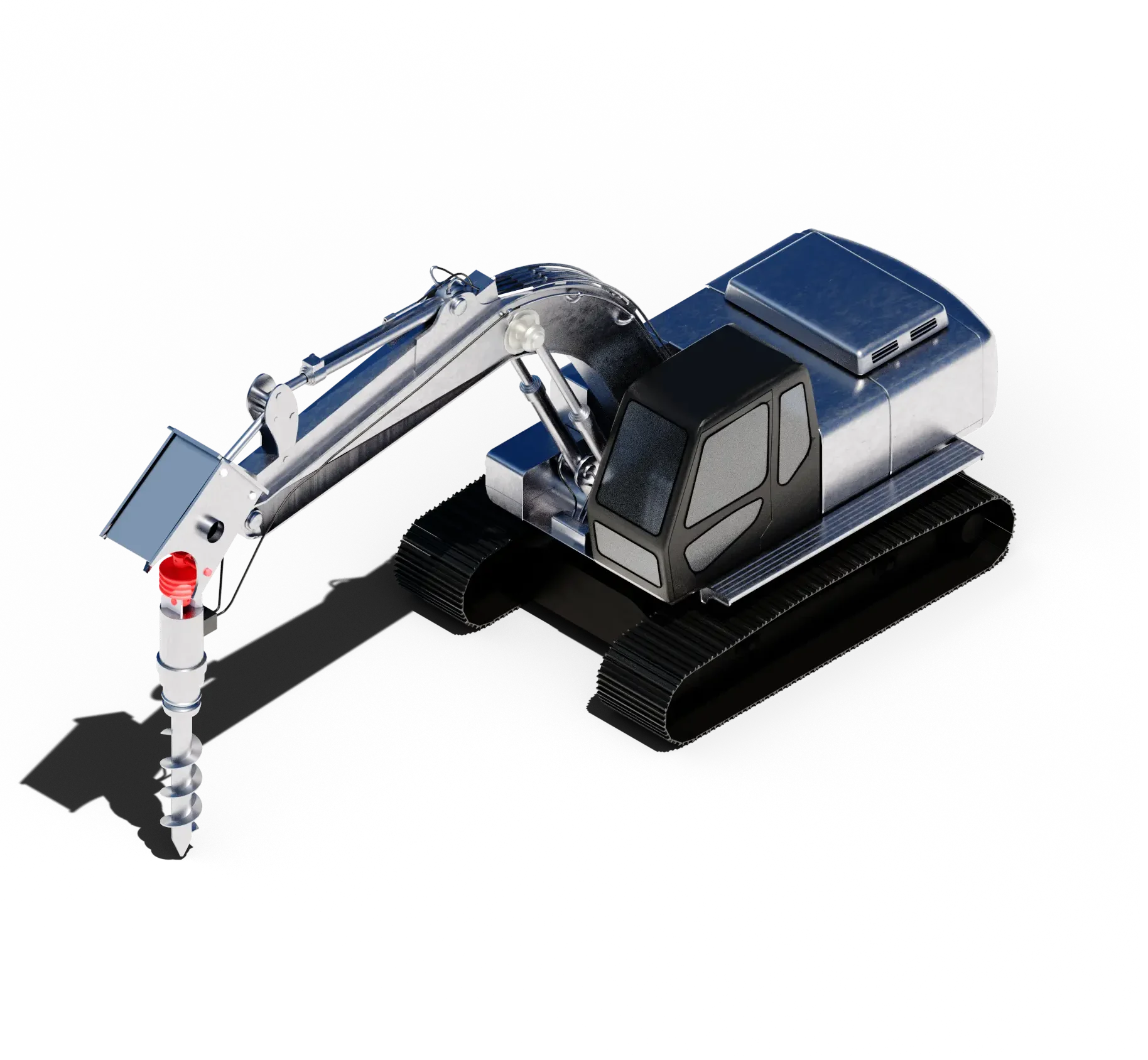

Torque Monitoring System for Auger Drills

Torque Load Cell Integration

As core equipment in pile foundation engineering, geological exploration, and mining, the operational quality and safety of auger drilling machines depends heavily on precise control of the drill-string torque. Torque information from ANYLOAD sensors not only indicates soil hardness, drill bit wear, and drilling efficiency, put also provides a quantitative defense against auger breakage, stuck drill events, and structural failure, increasing operational efficiency and safety.

Challenge

- Vibration & Impact: Drilling tools endure large cyclic impact loads, necessitating sensor fatigue resistance over prolonged operation.

- Site Contaminants: Harsh field environments expose sensors to debris such as dust and mud, requiring robust ingress protection, typically IP67 or higher.

- Wide Temperature Range: From -20°C to +85°C, sensors must avoid drift caused by thermal expansion/contraction of the body and temperature-dependent material property changes.

- Electromagnetic Interference: High power inverters and generators create strong interference, requiring strong protection against signal interference.

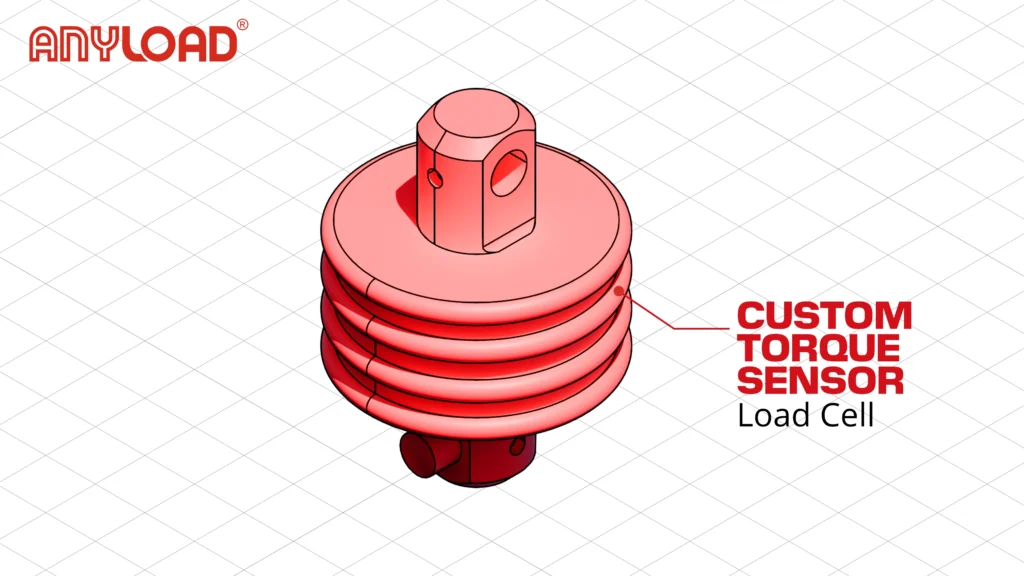

Solution

- Constructed from high-strength alloy steel engineered through mechanical analysis to withstand millions of high-impact cycles while safely handling loads exceeding 150% of full scale (FS) capacity.

- Designed with temperature compensation signal isolation measures that supress temperature-induced drift and EMI from surrounding equipment, ensuring long-term stability and accurate torque readings in harsh operating conditions.

- Built with a compact, high-stiffness structure that achieves a high natural frequency, enabling rapid response to changing torque loads.

- Paired with high-sample rate instrumentation, it enables real-time torque data acquisition and millisecond-level display of current torque values for immediate operator feedback.

Conclusion

The ANYLOAD Custom Torque Sensor for auger drills delivers reliable, high-accuracy torque monitoring by leveraging our company’s years of technical expertise in mechanical design with robust environmental protection. The rigid, high-stiffness structure ensures precise measurements under all loads even under vibration, temperature variation, and off-axis loading. The forged alloy steel construction allows for a built in 150% FS safety margin, significantly reducing failure rates.

Using a quick-release axial mounted design, replacement time can be as short as 30 minutes. The Custom Torque Sensor is a true plug-and-play replacement that requires no professional calibration on site, keeping downtime to a minimum. Additionally, ANYLOAD offers complimentary topology optimization services to tailor to each individual drill shaft, special constraints, and load characteristics as we understand the importance of a reliable structure in heavy machinery environments.

By emphasizing mechanical reliability, structural optimization, and stable long-term performance, the Custom Torque Sensor offers a dependable foundation for torque monitoring to enhance drilling efficiency, safety, and supporting more intelligent construction operations.

Keywords:

Torque Sensor, Auger Drills, IP67, Construction Operation, Quick Release Axial Mount.

Featured Products

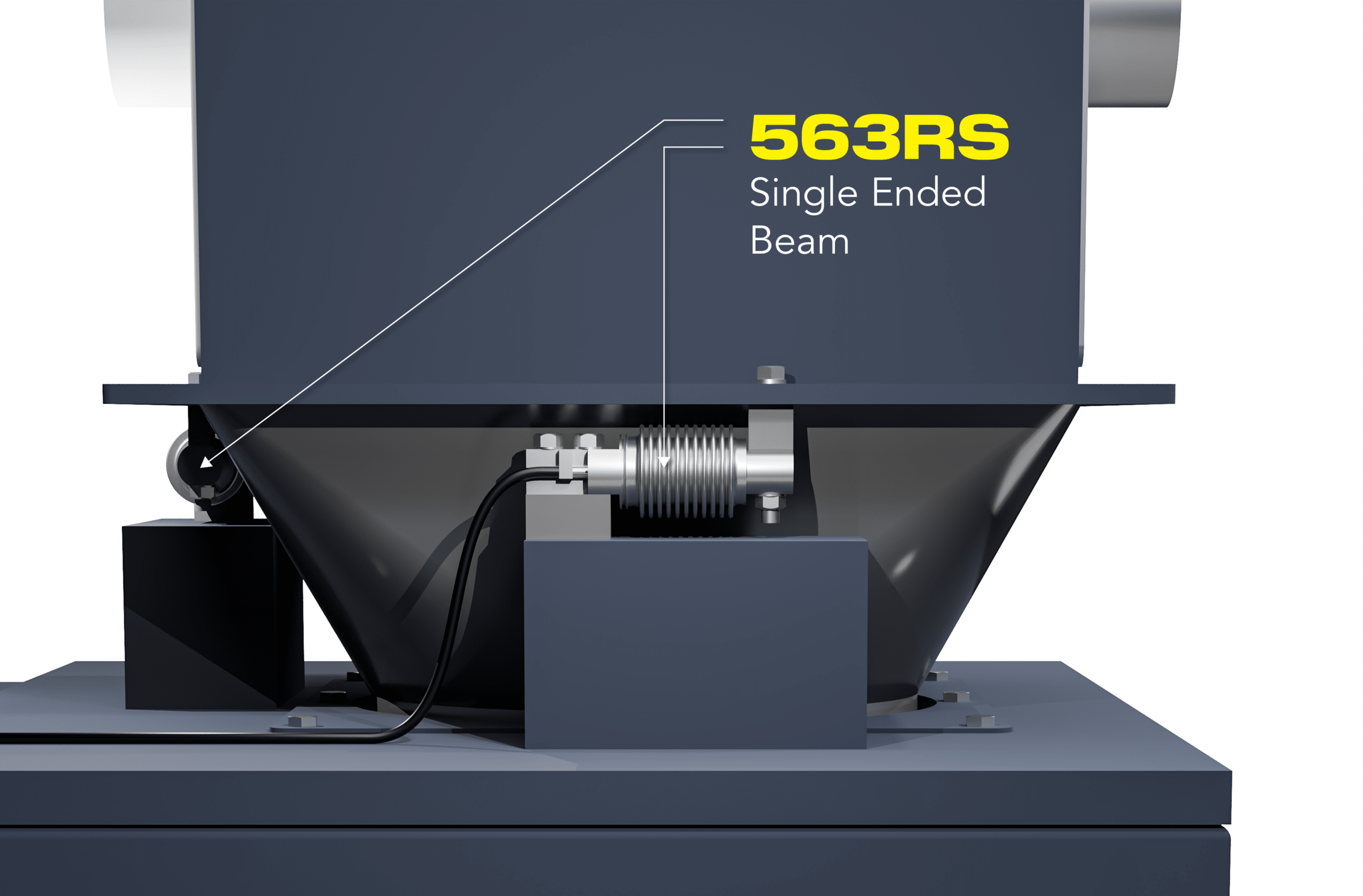

112BA

Torque Sensor

See standard version.

The 112BA Torque Sensor is a precision-manufactured IP65 force measurement solution that is compact and well suited to portable, hand-held applications, including torque gauges.

Features:

- Material: Aluminum, Clear Anodized

- Rated Capacities: 20in-oz, 50in-oz, 12in-lb, 50in-lb, 100in-lb, 0.14Nm, 0.35Nm, 1.5Nm, 5.6Nm, 11.3Nm

- Full Scale Output: 2.0mV/V ± 20%

- Safe Overload: 150% of full scale

- Seal Type/IP Rating: Environmentally Sealed/IP65

Agricultural Weighing Solutions

How agricultural industry uses our load cell for cart and mobile equipment for optimal result

Increase Turbine Life Span

Gravimetric quality assurance solution for wind turbine blades studies

Bag Filling Machine Load Cells

Bag filling and other process weighing and control system for maximal efficiency