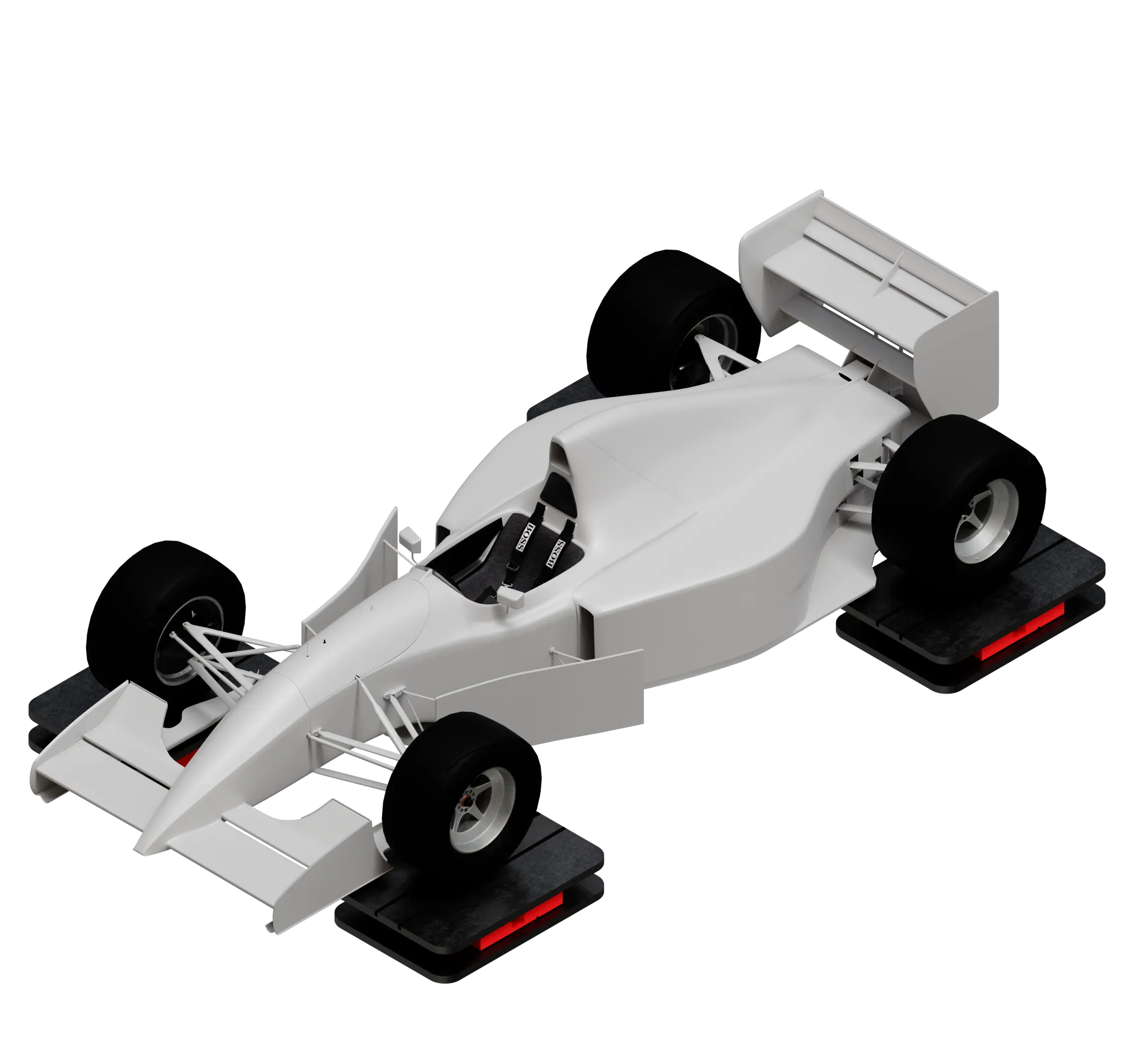

Precision Force for Performance Racing Industry

Challenge

- High Vibration Exposure: Racing vehicles operate in an environment with continuous vibration from engines, drivetrains, suspension movement, and road surface impacts.These vibrations can introduce noise, drift, and instability into force measurements, reducing confidence in setup data and making fine adjustments difficult.

- Four-Corner Weight Consistency & Corner Adjustment: Accurate four-corner weight measurement is critical during vehicle setup and corner balancing. Each corner must provide consistent and repeatable readings to ensure proper suspension balance, predictable handling, and even tire loading. Any deviation between corner measurements can lead to setup errors and compromised vehicle performance.

- Sensitivity Matching for Multi-Channel Measurement Systems: In multi-load-cell systems such as four-corner weighing platforms, mismatched sensor sensitivity can introduce measurement offsets between channels. Even small sensitivity variations can distort comparative weight readings, negatively impacting setup accuracy and repeatability. For motorsport applications, tightly matched sensitivity across all load cells is essential for meaningful corner-to-corner comparison.

Solution

High Natural Frequency & Vibration Resistance: An optimized structural design with a high natural frequency minimizes resonance effects,

reducing vibration-induced signal noise and improving measurement stability in high-vibration racing environments.Precise Corner Adjustment Through Consistent Output: ANYLOAD load cells provide stable, repeatable output across all four corners, enabling accurate corner balancing and suspension setup. Consistent measurement performance ensures that weight changes during adjustment are correctly reflected at each corner, allowing engineers to achieve balanced load distribution and predictable handling characteristics.

Matched & Tuned Sensitivity Across All Load Cells: All load cells are individually calibrated and sensitivity-matched to 2.0 mV/V, with a tight tolerance of ±0.25%. This ensures uniform response across all measurement channels, minimizing corner-to-corner deviation and improving the accuracy of comparative weight analysis in four-corner and multi-sensor racing applications.

This level of matching ensures that weight changes observed during setup reflect true mechanical adjustments rather than sensor variation.

Conclusion

Keywords:

Racing Industry, Racing, 108HAUN, Single Point Load Cell, Racing Car, Corner Balancing, Braking Analysis.

Featured Products

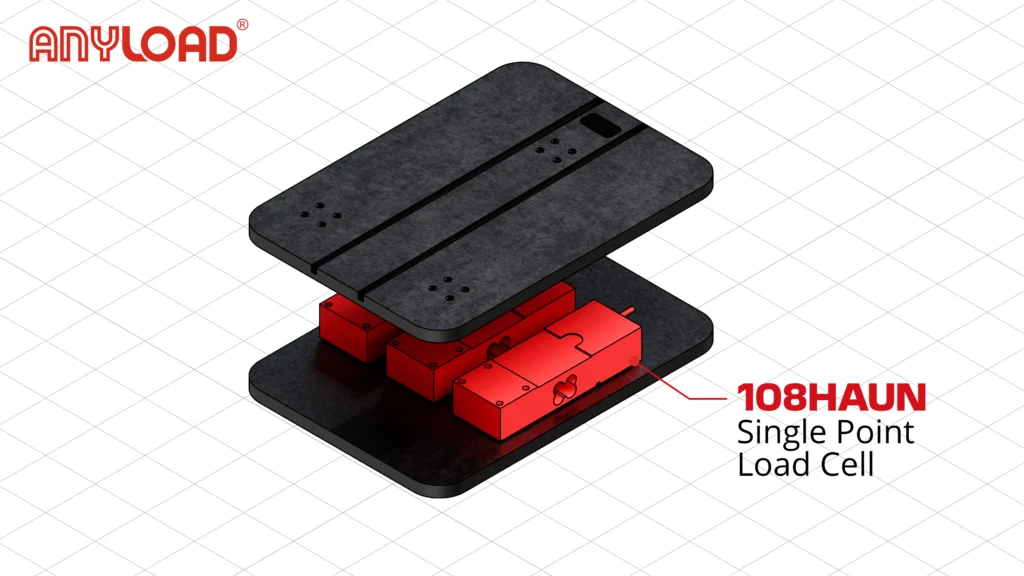

108HAUN

Single Point Load Cell

See standard version.

- Material: Aluminum, Clear Anodized

- Rated Capacities: 50kg, 100kg, 250kg, 635kg, 1t

- Full Scale Output: 2mV/V ± 0.25%

- Safe Overload: 150%

- Breaking Overload: 300%

- IP Rating: IP66

- 50 kg up to 500 kg: Certified up to OIML MAA C5, Y=12300

- 500 kg up to & including 1t: Certified up to OIML MAA C4, Y=4000

- CE and RoHS certified

Agricultural Weighing Solutions

How agricultural industry uses our load cell for cart and mobile equipment for optimal result

Increase Turbine Life Span

Gravimetric quality assurance solution for wind turbine blades studies

Bag Filling Machine Load Cells

Bag filling and other process weighing and control system for maximal efficiency