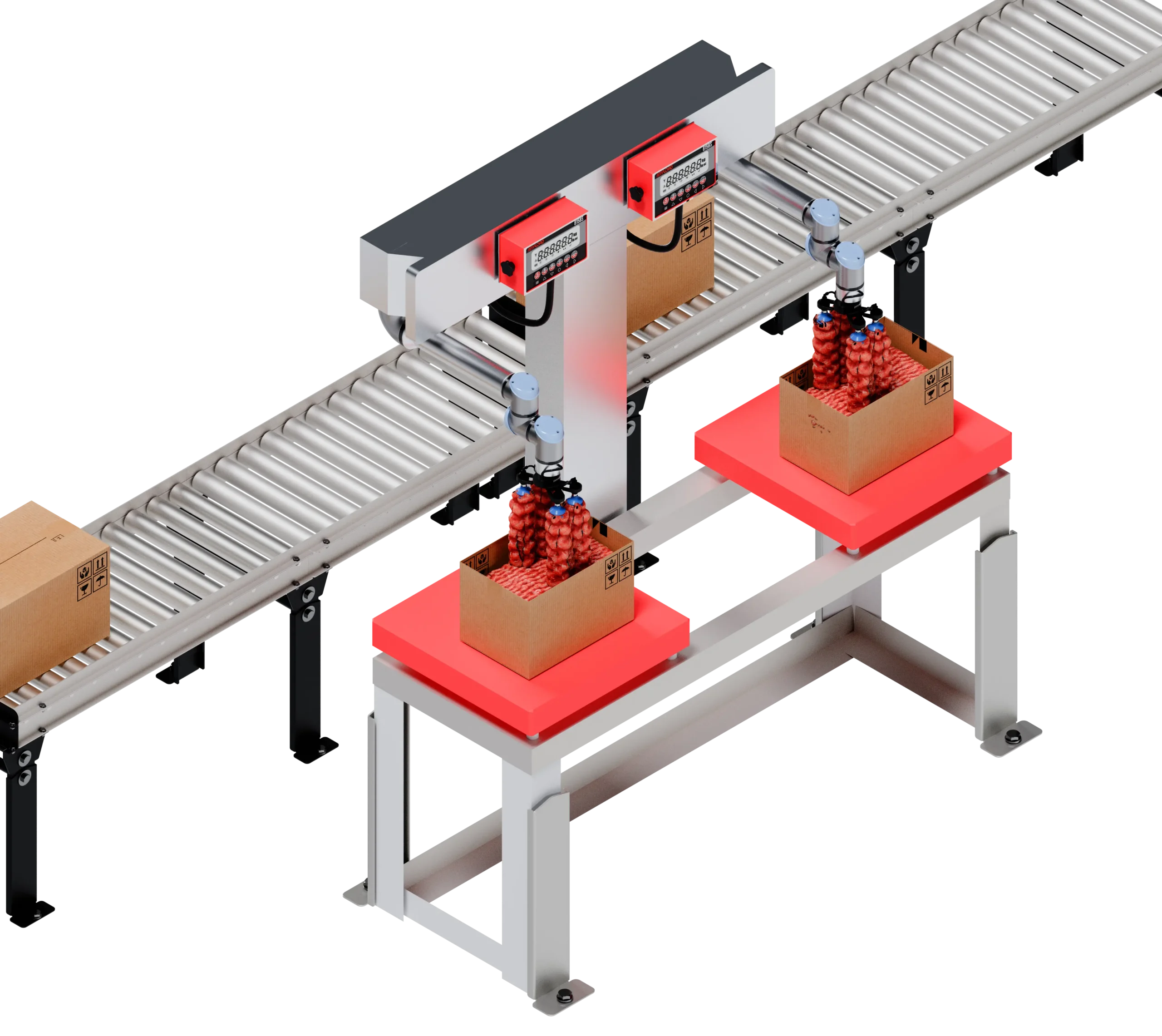

Box Filling Station

Box Fill Station with Integrated Bench Scale for Ground Meat Processing

In automated meat processing environments, automated box filling stations must deliver consistent, accurate weights to ensure efficiency and regulatory compliance. To meet the need for precise portion control, the ANYLOAD TNS stainless steel bench scale was integrated directly into the station, serving as a fully sanitary scale that provides live feedback during filling operations.

Challenge

- Accurate Live Weighing: The system must deliver precise weight readings during dynamic filling of the box with solid content, maximizing control over the final product weight.

- Wash-down Compatibility: Operating in a food processing environment requires IP-rated components and stainless steel surfaces to meet sanitation requirements.

- Weigh Stability During Vibration: The filling process of solids introduces vibrations that the scale must reject to maintain stable readings even under light disturbances.

- Integration with Automation: The scale must provide rapid weight feedback compatible with automation systems, allowing proper integration of box changeovers when the target weights are reached.

Solution

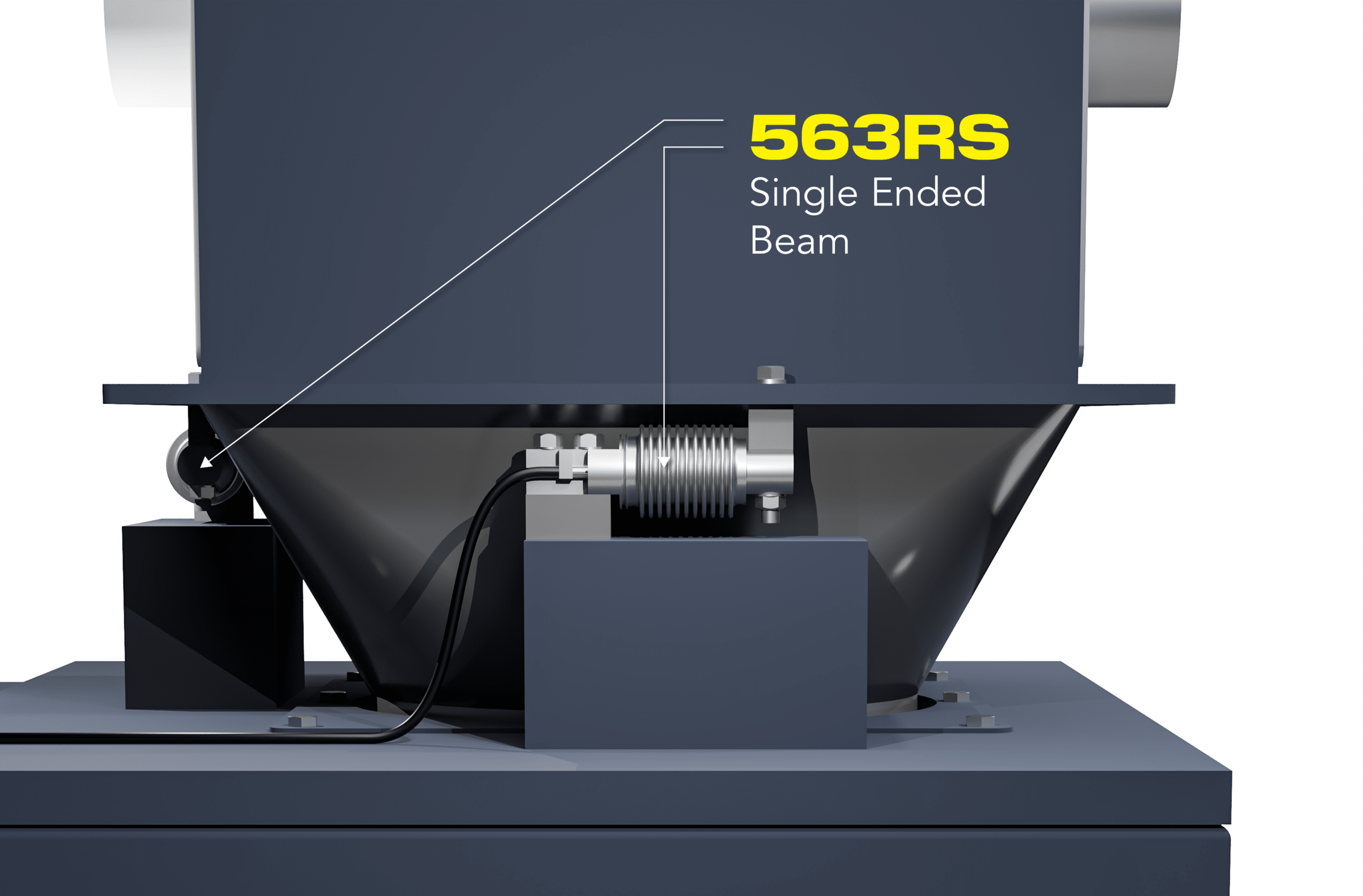

- The ANYLOAD TNS stainless steel bench scale was chosen for its footprint, IP67 washdown protection, and stable weight response on all corners of the scale.

- The scale is mounted directly on the boxing platform, allowing continuous feedback as the box is continuously filled with ground mat from the conveyor chute above.

- Real-time digital readout allows operators to visually track fill weights and stop the conveyor or adjust fill timing as needed without greatly affecting the process line.

- Integration with the box fill system allows use of feedback logic, leading to semi or fully automatic batching if desired, increasing efficiency and throughput.

Conclusion

The integration of ANYLOAD’s TNS bench scale into the box filling station supports fast, hygienic, and accurate filling of ground meat into shipping boxes. The compact and industrial design make it a reliable solution for demanding and regulated food production environments. For more information on sensors and custom applications, please contact ANYLOAD.

Featured Products

815BS

Industrial Weight Indicator

See standard version.

The ANYLOAD 815BS LCD Weight Indicator delivers high accuracy, reliability, and multiple functions for industrial, food, and agricultural applications. It features password-protected calibration, electronic sealing with audit trail, advanced filtering, and supports up to 4×350 Ω or 8×700 Ω load cells. The SS304 stainless steel, NEMA4X/IP66 enclosure ensures durability in harsh environments.

- 1.0” 6-digit LCD with tri-color backlight (green/red/amber)

- Displays kg, lb, oz, g; gross, net, tare; stability & center of zero

- Easy screw-terminal wiring

- Password-protected setup & calibration

- Two RS232 ports, UL-approved adapter

- Built-in lithium battery with charger

- Weatherproof with breather vent to prevent condensation

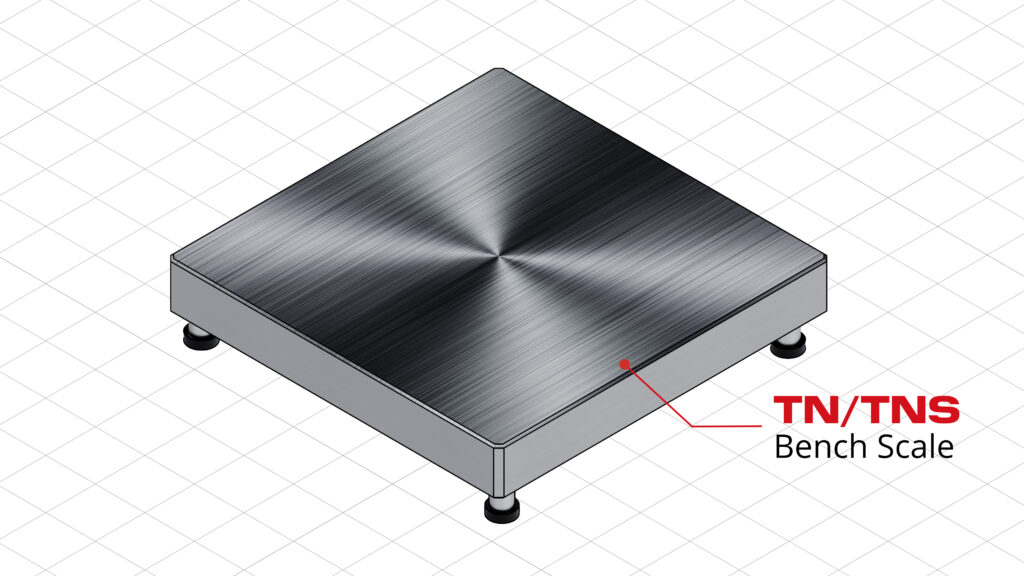

TNS Series

Stainless Steel Bench Scale

See standard version.

- Measurement Canada and NTEP certified, capacities from 15kg to 300kg, platform sizes from 12 inch x 12 inch to 24 inch x 24 inch

- Heavy gauge stainless steel (SS304) construction

- Heavy gauge stainless steel platform

- Supplied with bracket, column, column holder, level bubble and load cells

- Breaking Overload: 150% of full scale

- NTEP certified load cells from 200kg-400kg

- CE, RoHs, Measurement Ukraine and Measurement Spain certified load cells

- Indicator is sold separately

Agricultural Weighing Solutions

How agricultural industry uses our load cell for cart and mobile equipment for optimal result

Increase Turbine Life Span

Gravimetric quality assurance solution for wind turbine blades studies

Bag Filling Machine Load Cells

Bag filling and other process weighing and control system for maximal efficiency