Soluciones a medida

ANYLOAD designs and manufactures custom weighing and force measurement solutions for OEMs, scientific, and industrial applications worldwide. Our engineering teams support projects ranging from initial feasibility and prototype development through to validated, scalable mass production.

Our custom solutions are deployed globally across demanding industries and operating environments, where performance, reliability, and supply continuity are critical.

Tailored Measurement Solutions

Scalable solutions ranging from minor sensor modifications to fully bespoke OEM weighing systems.

ANYLOAD provides a flexible approach to custom weighing and force measurement solutions, supporting everything from minor load cell modifications to fully engineered-to-order force sensors and OEM weighing systems. With decades of applied design and manufacturing experience, we adapt existing designs or develop new sensor architectures to meet specific mechanical, electrical, environmental, regulatory, and integration requirements. This agility allows us to support rapid adjustments, complex system integration, and mission-critical applications requiring high precision, validation, and long-term reliability across a wide range of industries and operating conditions.

Modification

Small Changes to standard load cell designs.

Typical Modifications:

- Cable Length, Type, Connector

- Thread Size

- Embedded Surge Protection

- Overload or Sensitivity Adjustment

- Material or Coating Change

Customization

Function & Integration changes to exisiting designs.

Customization Options:

- Unique Dimensions

- Salida digital

- Multi-Bridge Redundancy

- High-Temp Resistance

- Optimize for In-Motion or Process Weighing

Engineered-To-Order

Fully custom force sensor for unique applications.

Custom Product Options:

- Miniaturization

- Multi-Axis Sensing

- Testing & Validation

- High Precision

- Extreme Environmental Resistance

Customizations

ANYLOAD is an engineering-led manufacturer with extensive experience delivering custom weighing and force measurement solutions for industrial and OEM applications. Our multidisciplinary teams combine sensor design, testing capabilities, and manufacturing expertise to address complex mechanical, environmental, and integration challenges. Through an established Engineer-to-Order (ETO) capability and broad in-house resources, we support programs ranging from specialized load cell adaptations to fully custom force sensors, delivering reliable and repeatable performance in demanding operating environments worldwide.

System Integration

System-level integration requirements often extend beyond the sensor, affecting signal connectivity, calibration, and regulatory compliance. Customization options such as digital or analog output formats, application-specific connectors, tailored calibration proceduresy certification support are critical to ensuring reliable performance within larger control, automation, or data acquisition systems. By addressing these integration constraints during the design and validation stages, custom load cells and force sensors can be deployed with predictable accuracy, reduced commissioning effort, and long-term stability across diverse operating conditions and regulatory environments.

Output Signal

We support custom signal outputs for PLC and control system integration, including analog outputs (0–10 V, 4–20 mA), digital interfaces (RS232, RS485 Modbus, CANopen, J1939), and fully integrated digital load cell designs.

Custom Connector

Connector configurations can be customized to match existing industrial cabling, environmental requirements, and mechanical constraints. Options include application-specific connector types, pinouts, orientations, and strain relief to simplify installation and improve long-term reliability.

Special Calibration

Calibration can be tailored to specific loading conditions, installation geometries, and accuracy requirements. Application-specific calibration improves measurement accuracy, reduces system-level error, and supports consistent long-term performance.

Certification Support

Many load cells and force sensors are already designed to meet common certification requirements, with additional certifications available by contract where required. Existing certified designs can often be adapted to new applications, reducing approval effort, cost, and deployment time.

Challenging Environments

Challenging operating environments can significantly affect sensor accuracy, stability, and service life. Drawing on extensive experience across aerospace, medical, scientific, semiconductor, and advanced manufacturing applications, ANYLOAD engineers load cells and force sensors for extreme conditions using controlled material selection, sealing methods, and in-house facilities for environmental and temperature-compensation testing under load to ensure reliable performance in demanding real-world deployments.

Extreme Temperature

Sub-zero and elevated temperatures can alter material behavior, strain response, and signal stability. Custom designs incorporate extended temperature compensation ranges and specialized electronics to maintain accuracy in cryogenic and high-temperature applications.

Radiation Tolerance

Ionizing radiation can degrade materials, adhesives, and electronic components over time. Load cells and force sensors can be adapted using radiation-tolerant design practices to support stable operation in controlled radiation environments common to scientific, medical, and aerospace systems.

Protección contra la penetración

Exposure to moisture, washdown, or submersion can lead to corrosion, leakage, and signal drift. Custom sealing approaches, including hermetic construction and high IP/NEMA ratings, support reliable operation in underwater, hygienic, and high-pressure industrial environments.

Vacuum

Vacuum conditions introduce challenges related to outgassing, thermal dissipation, and material compatibility. Vacuum-compatible load cells and force sensors are engineered to enable stable, repeatable measurement in semiconductor, scientific, and controlled-atmosphere applications.

Sensor Integrity

Mechanical, electrical, and dynamic stresses affect sensor integrity, accuracy, and service life, particularly in mobile, high-cycle, and safety-critical applications. ANYLOAD designs load cells and force sensors with durability and reliability as core engineering considerations, drawing on experience with fatigue-rated designs, overload protection, shock and vibration resistancey electrical transient mitigation. By addressing these factors at the sensor level, we support stable measurement performance and long-term reliability under demanding real-world operating conditions.

Fatigue Rated

Repeated loading cycles can lead to material fatigue and gradual performance degradation. Fatigue-rated load cells are designed and tested for high-cycle operation, supporting mobile equipment, dynamic weighing, and vibration-prone applications where long-term durability is critical.

Overload Protection

Overloads cause permanent sensor damage or unsafe system behavior. Custom designs may incorporate high safe overload and breaking overload margins to improve safety factors, supporting reliable operation in safety-critical and mechanically demanding installations.

Shock & Vibration

Shock events and continuous vibration introduce rapidly changing loads that challenge measurement stability. Load cells engineered for shock and vibration resistance support dynamic weighing, checkweighing, and mobile systems where fast response and structural robustness are required.

Surge Protection

Electrical transients from lightning, welding equipment, or unstable power supplies can damage sensor electronics and disrupt signal integrity. Integrated surge protection can be incorporated at the sensor level to improve resilience and reliability in electrically noisy industrial environments.

Specialized Form & Materials

Physical constraints, material compatibility, and system lifecycle considerations can dictate sensor design as much as nominal capacity or accuracy. ANYLOAD engineers load cells and force sensors using specialized form factors and material selections to support space-constrained installations, legacy system replacementy operation in sensitive medical, scientific, and industrial environments. This includes adapting geometry, interfaces, and materials to ensure compatibility, repeatability, and long-term deployability in applications where standard sensor designs are not suitable.

Miniaturization

Limited installation space can restrict sensor geometry, mounting options, and cable routing. We engineer miniaturized load cells and force sensors to deliver reliable measurement performance within compact envelopes for tightly integrated or embedded applications.

Legacy Design

Aging or discontinued sensors can present long-term maintenance and supply challenges. Custom designs can replicate legacy form factors, enabling drop-in replacement of out-of-production or difficult to source load cells while maintaining full system compatibility.

Non-Magnetic

Magnetic materials can interfere with sensitive equipment and measurement environments. Non-magnetic load cells and force sensors are available using carefully selected materials to support medical imaging, scientific instrumentation, and other magnetically sensitive applications.

Multi-Axis Sensing

Complex or off-axis loading require measurement beyond a single force direction. Multi-axis load cells and force sensors capture forces across multiple axes while minimizing cross-talk, supporting advanced robotics, testing, and precision industrial applications.

Our Services

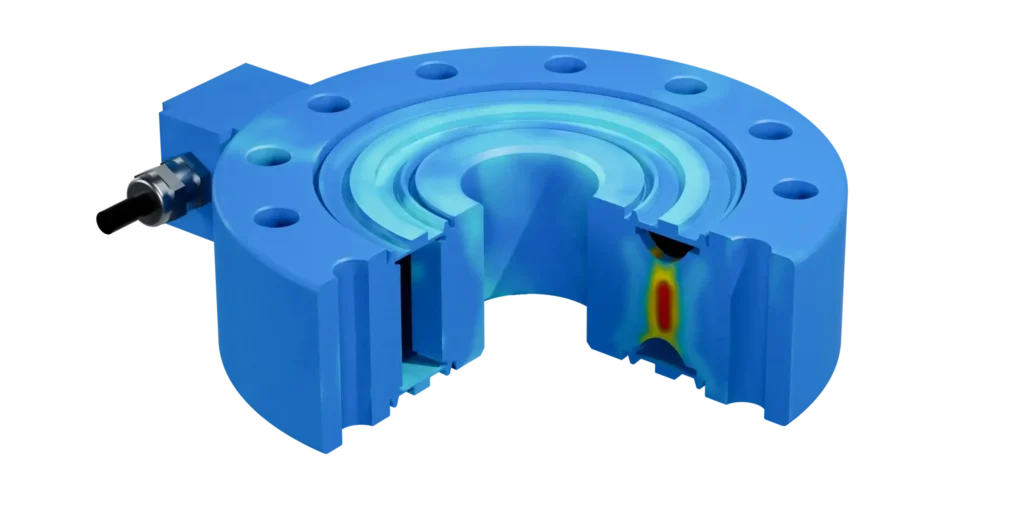

Engineering & Design

Applied engineering support for custom weighing and force measurement systems, including load cell and scale design consultation, mechanical reviewy finite element analysis (FEA). These services help optimize load paths, safety factors, and measurement accuracy early in the design cycle.

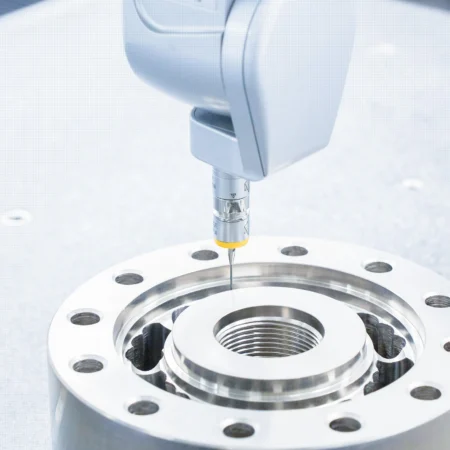

Measurement & Testing

Force measurement and validation services supporting custom applications, including strain gauging, instrumentation, and development of application-specific test rigs. These capabilities enable accurate force characterization and performance verification under real operating conditions.

Manufacturing & Integration

Manufacturing and integration support for complete weighing and force measurement systems, including sourcing, fabrication, assemblyy system-level integration. This ensures custom solutions are delivered as deployable, production-ready assemblies rather than standalone components.

Calibration & Certification

Calibration, certification, and lifecycle services supporting accuracy, compliance, and long-term reliability. This includes factory and in-service calibration, repair y refurbishment, and assistance with certificación and regulatory requirements.

Custom Load Cell Types

Used in joints and rotating assemblies where direct force measurement replaces standard pins in industrial, lifting, and mobile applications.

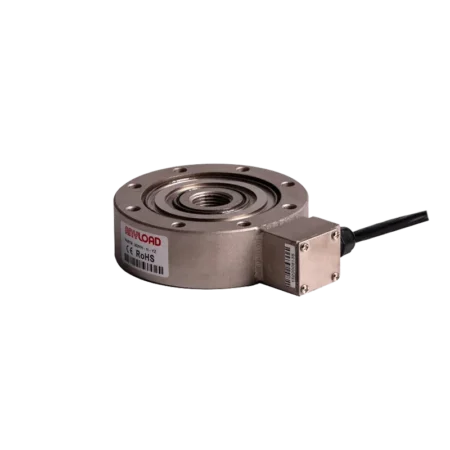

High-capacity and structural applications where load symmetry and long-term stability are critical.

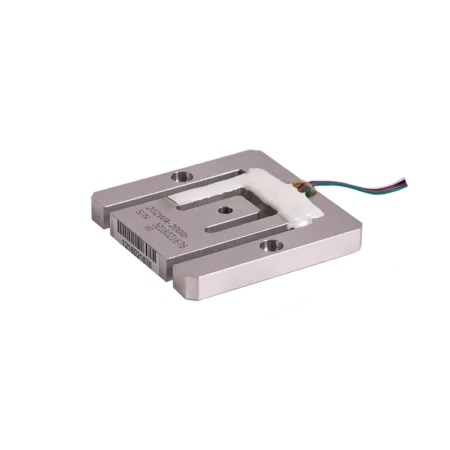

Designed for flat or embedded installations where traditional beam or column sensors cannot be accommodated.

Used in confined mechanical assemblies and test setups where localized force measurement is required within limited space.

Used across industrial and OEM systems for inline tension and compression measurement where mounting and system integration vary by application.

Used in heavy industrial and process weighing systems where high compressive loads and structural alignment are primary considerations.

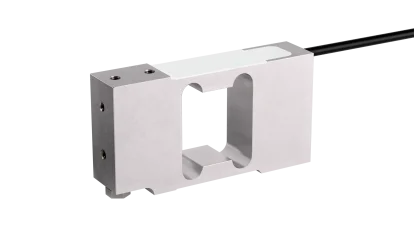

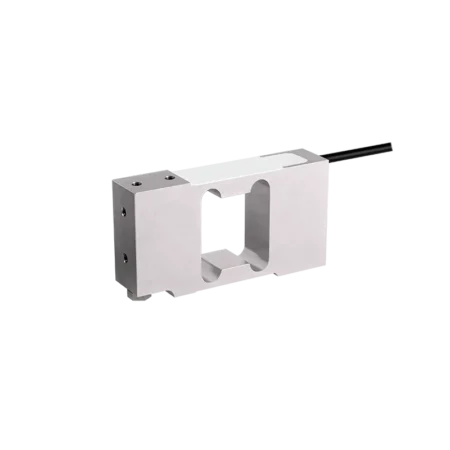

Common in compact and platform-based weighing systems where mechanical layout and load behavior influence performance.

Applied in advanced systems where forces act in multiple directions, such as robotics, testing, and precision industrial applications.