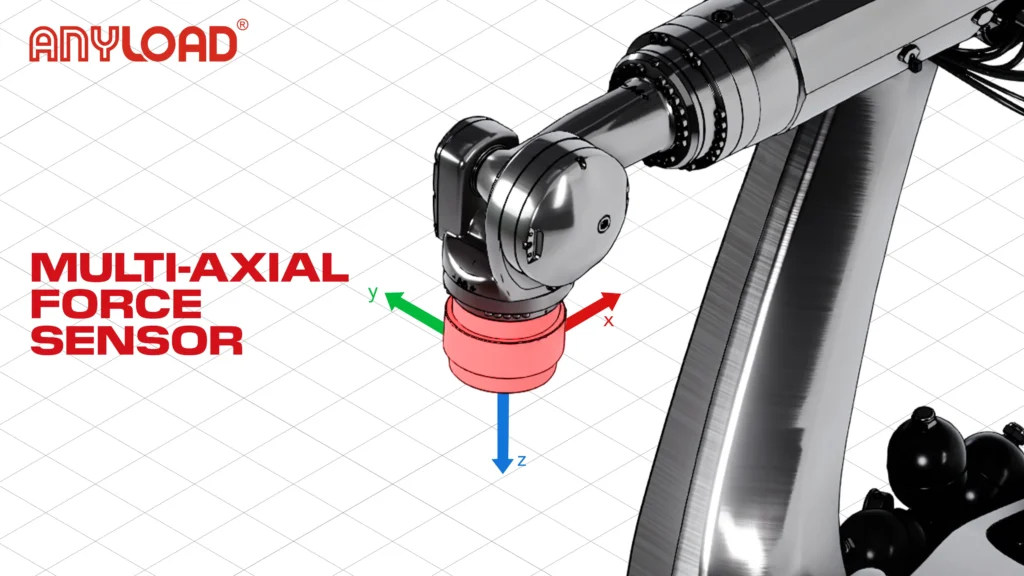

Multi-Axial Force Sensor for

Automatización robótica

Optimizing Robotic Sensors for Precision and Durability

Robotic arms are programmable automated devices widely used in industrial production, medical surgeries, agriculture, and other fields. In industrial production, robotic arms perform repetitive tasks such as welding, painting, assembly, and material handling with precision, improving efficiency and reducing labor costs. In agriculture, robotic arms are used in precision farming for tasks like seeding, fertilizing, and harvesting, executing operations efficiently as per pre-set programs.

With ongoing technological advancements, robotic arms are becoming increasingly intelligent. By equipping them with multi-axis sensors, robotic arms gain mechanical sensing capabilities, enabling precise force control and enhancing efficiency and safety.

Desafío

Despite the promising applications of robotic arms across various industries, their sensors face multiple challenges in design, production, and application:

- Accuracy and Stability: The effective operation of robotic arms relies on high-precision sensors. However, in complex working environments, especially with multiple motors in robotic arms, sensors are prone to interference, leading to inaccurate readings.

- Environmental Adaptability: In diverse working environments such as high temperatures, humidity, or dusty conditions, sensor performance can be compromised, affecting the normal functioning of robotic arms.

- Integration Complexity: Since robotic arms need to measure forces across at least two to six dimensions, multiple Wheatstone bridges are required in sensor design. Additionally, the influence of cross-axis coupling must be considered.

Solución

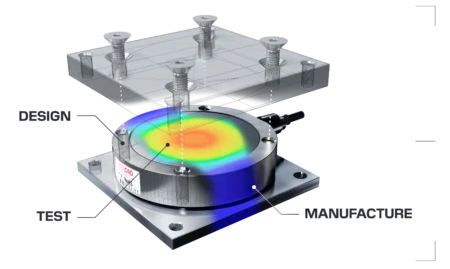

To address these challenges, ANYLOAD engineers have conducted simulations and testing to propose several solutions:

- Enhancing Sensor Accuracy and Anti-Interference Capability: By improving sensor designs, adding shielding features, and optimizing signal transmission cables, interference resistance and accuracy can be significantly improved.

- Developing Environmentally Resilient Sensors: The sensor design incorporates multiple layers of sealing, each with distinct sealing functions, making sensors highly resilient to environmental factors.

- Modular Design: Modular designs for different multi-dimensional force sensors allow for easier production and testing. Integrated modular designs improve production efficiency and quality.

Conclusión

Robotic arms hold immense potential across various industries, with sensors being the key to their efficiency and precision. ANYLOAD’s innovative sensor designs enhance sensor performance and adaptability. The internal modular design approach significantly improves structural design, production, and quality.

We also offer customized design, production, and mass manufacturing services tailored to different robotic arm application scenarios.

Palabras clave:

Multi-Axis Sensor, Robotics Sensor.

Productos destacados

ANYLOAD’s custom weighing and force measurement solutions have been deployed across a vast number of industries and applications globally. Our experienced customer service and engineering teams provide responsive turnaround times from initial consultations, prototypes, through to production. Reach out to our specialists to experience the ANYLOAD difference.

Soluciones de pesaje agrícola

Cómo utiliza la industria agrícola nuestra célula de carga para carros y equipos móviles para obtener un resultado óptimo

Aumentar la vida útil de la turbina

Solución gravimétrica de garantía de calidad para estudios de palas de aerogeneradores

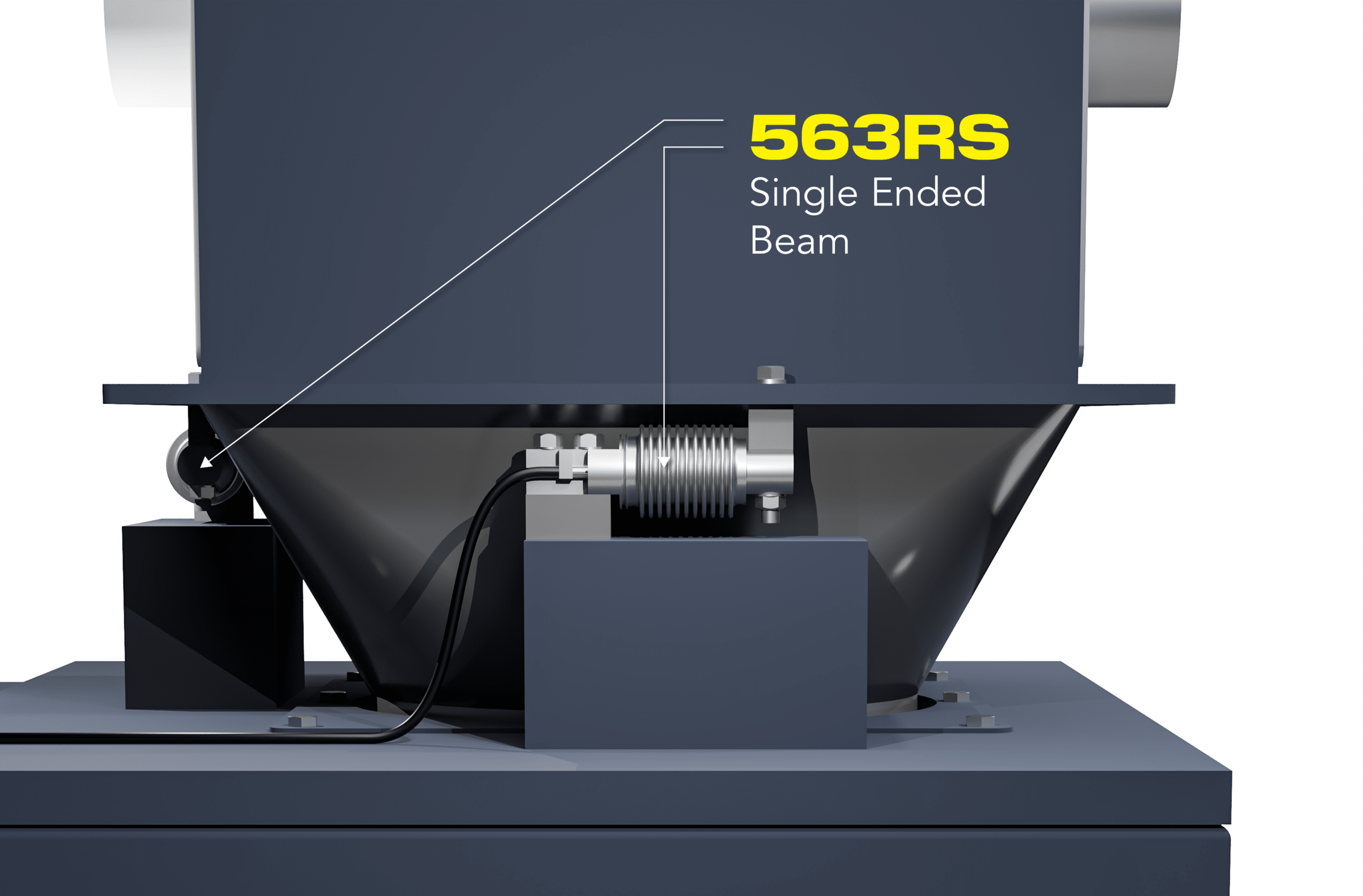

Células de carga para máquinas llenadoras de bolsas

Sistema de pesaje y control del llenado de bolsas y otros procesos para lograr la máxima eficacia