Truck Scales – Design & Fabrication

Last Updated On January 21, 2026 • 10 min read

This section explores the design and fabrication of truck scales, covering deck types, load cell configurations, foundation options, and construction methods. Understanding these elements is essential for anyone specifying, purchasing, or maintaining a truck scale, as design directly impacts accuracy, reliability, and long-term operating cost.

Importance of Good Scale Design and Fabrication

Design governs reliability and serviceability

The structure of a scale determines how forces are distributed, how easily it can be installed, and how quickly it can be serviced when maintenance is needed. A well-designed scale:

- Distributes load evenly to prevent fatigue and deflection

- Allows easy access to load cells and cabling for faster servicing

- Minimizes downtime by simplifying alignment and calibration

- Performs consistently across varying environmental and foundation conditions

Fabrication governs quality and structural integrity

Even the best design fails without precision manufacturing. The fabrication process (cutting, welding, cambering, and surface finishing) dictates how strong, stable, and long-lasting a scale will be. High-quality fabrication:

- Ensures proper weld penetration and alignment across all bridge sections

- Maintains tight tolerances for accurate load transfer

- Uses automated bead blasting and oven paint curing for corrosion resistance

- Produces uniform deck flatness and stability under repeated loads

When both elements are optimized, the result is a truck scale that not only weighs accurately but also withstands the realities of field use: heavy axle impacts, seasonal temperature swings, debris buildup, corrosive environments, and years of constant traffic.

Scales built with this philosophy, like ANYLOAD’s ORCA™ and OTTER™ series, combine advanced orthotropic design with precision CNC fabrication to deliver the highest standard of reliability, serviceability, and long-term value.

Truck Scale Designs

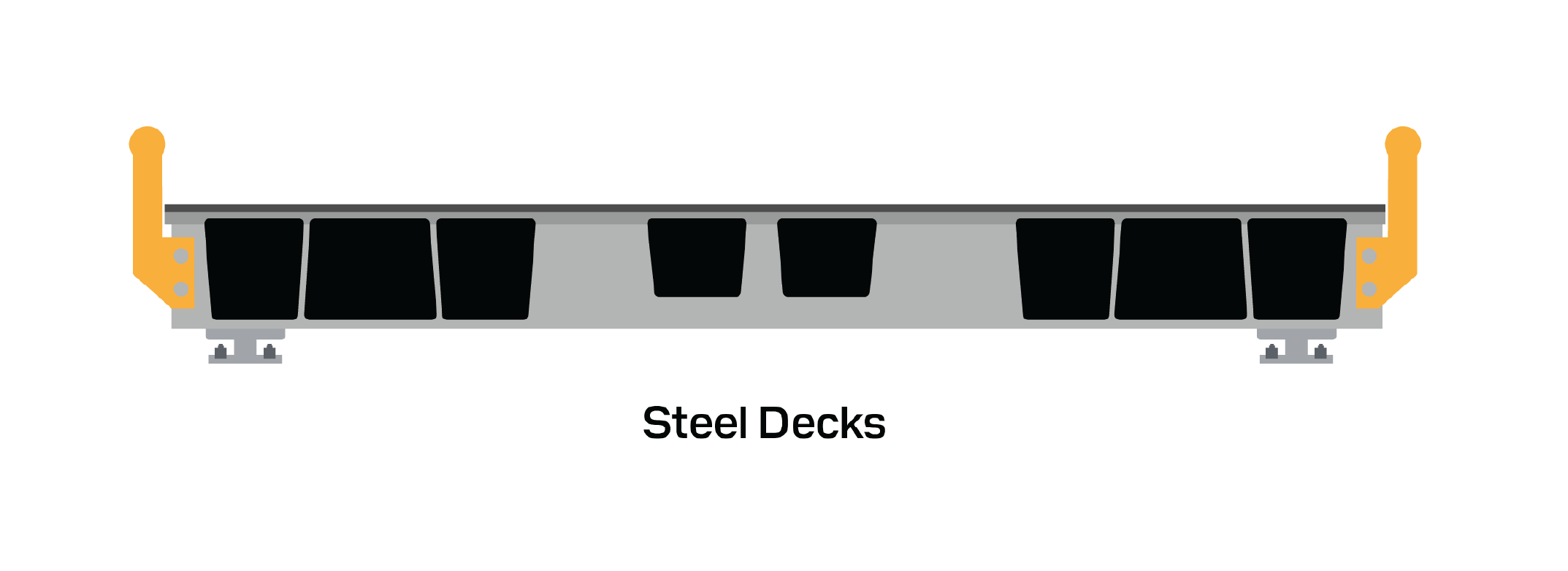

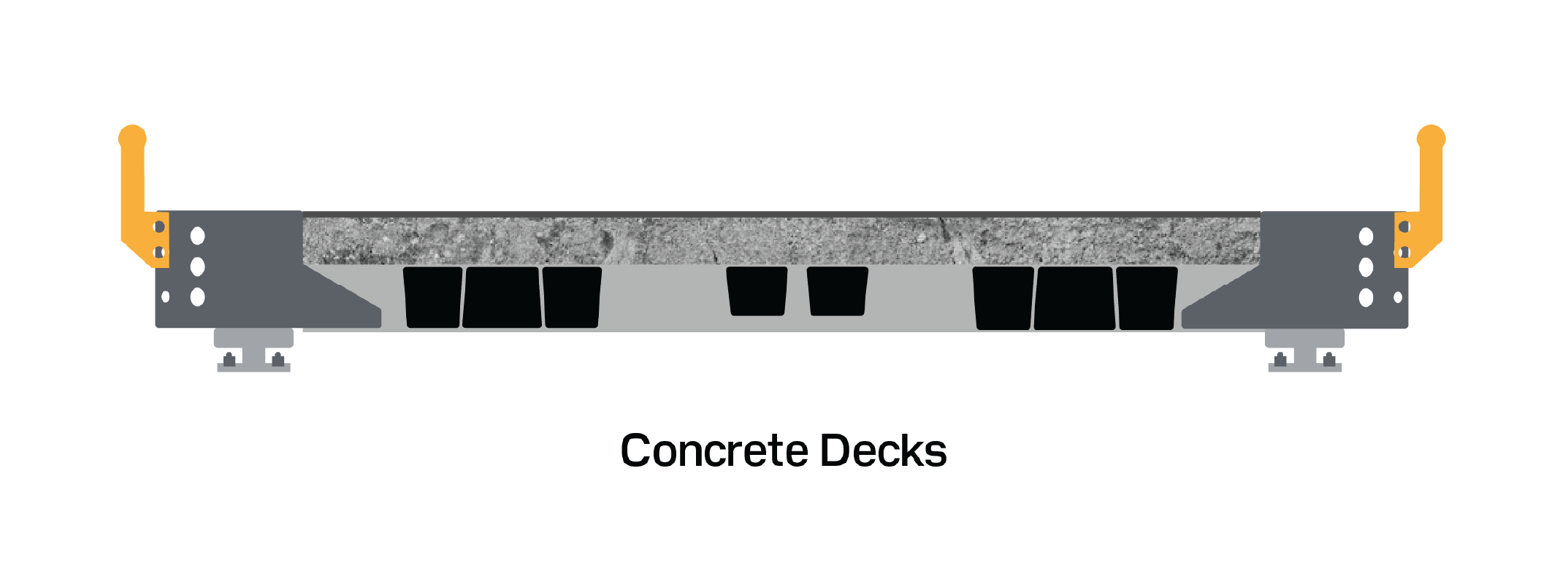

Steel vs. Concrete Top Deck

Most truck scales are built with either steel or concrete decks, each suited for different priorities:

- Steel Decks: Prefabricated entirely from steel and ready to use on delivery. Steel decks are ideal for operations that require fast installation, relocation, or portable use. They are lighter, allowing for simpler foundations and installation processes, and their tread-plate surface provides excellent grip, even in wet conditions. Their weight makes them more portable and serviceable as well. A well-designed and fabricated steel deck weigh-bridge can last just as long a concrete equivalent.

- Concrete Decks: Cast-in-place or pre-cast on-site, these decks offer higher mass (~4x heavier) and natural dampening, which can marginally benefit accuracy in high-traffic or outdoor installations. However, they require significant curing time for poured concrete (up to 30 days, which can significantly disrupt site operations) and are more permanent due to their weight. Maintenance is low, but the installation process is significantly more involved.

NOTE: Modern steel deck weighbridges, especially from a reputable manufacturer, will perform just as well as a concrete deck truck scale. This is due to advancements in design and fabrication techniques.

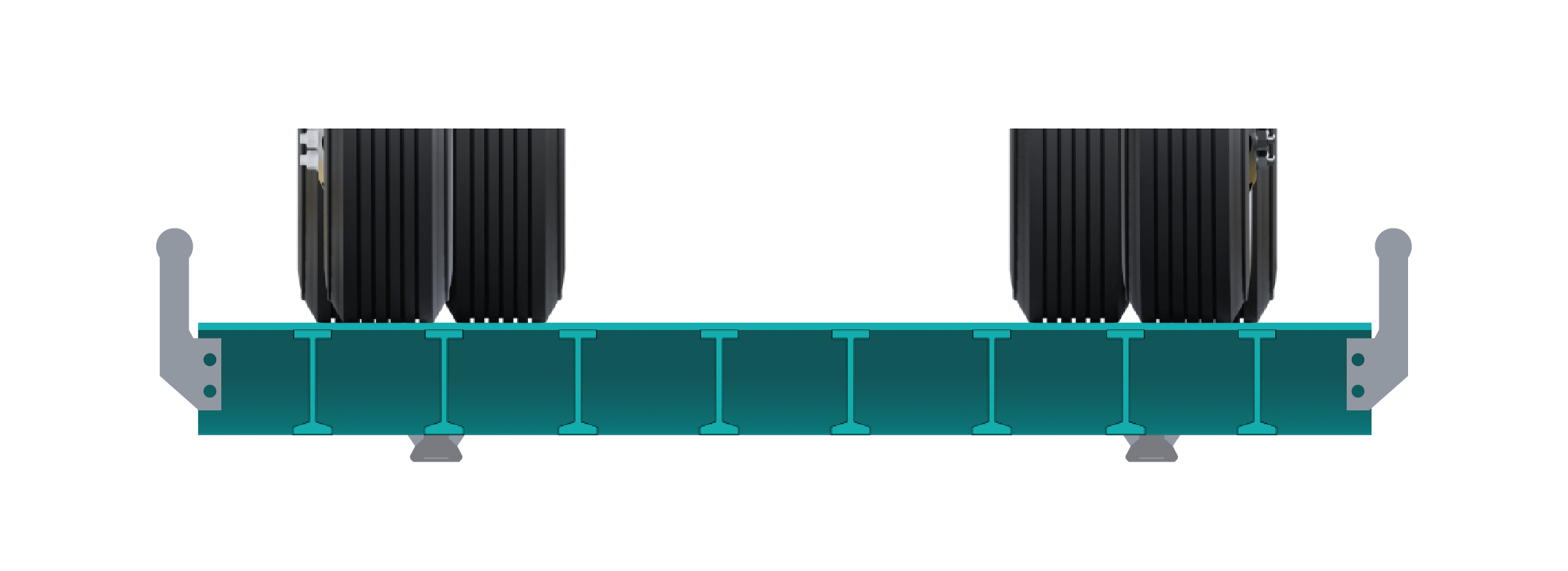

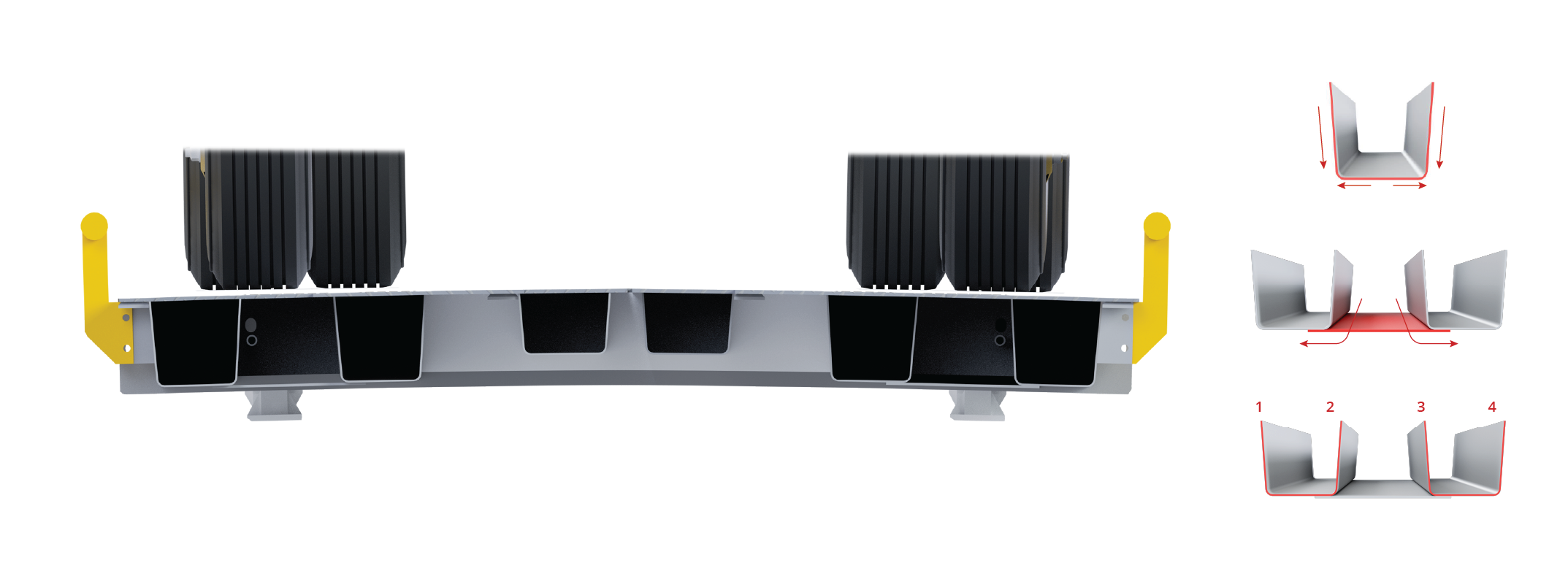

I-Beam vs. U-Channel Construction

Truck scale weighbridges rely on structural beams beneath the deck to carry the vehicle load. These beams are typically arranged in either an I-beam or U-channel (orthotropic) configuration. This design choice affects the scale’s long-term durability, maintenance needs, and weighing accuracy.

- I-Beam construction is common because standard I-beams are widely available from steel mills and are simple to weld onto a top plate and fabricate into deck modules. However, I-beams tend to concentrate stress along a few primary members, leading to localized deflection and fatigue in high-traffic areas over time. Open underside can also allow moisture, oxygen, and salt intrusion to accelerate corrosion.

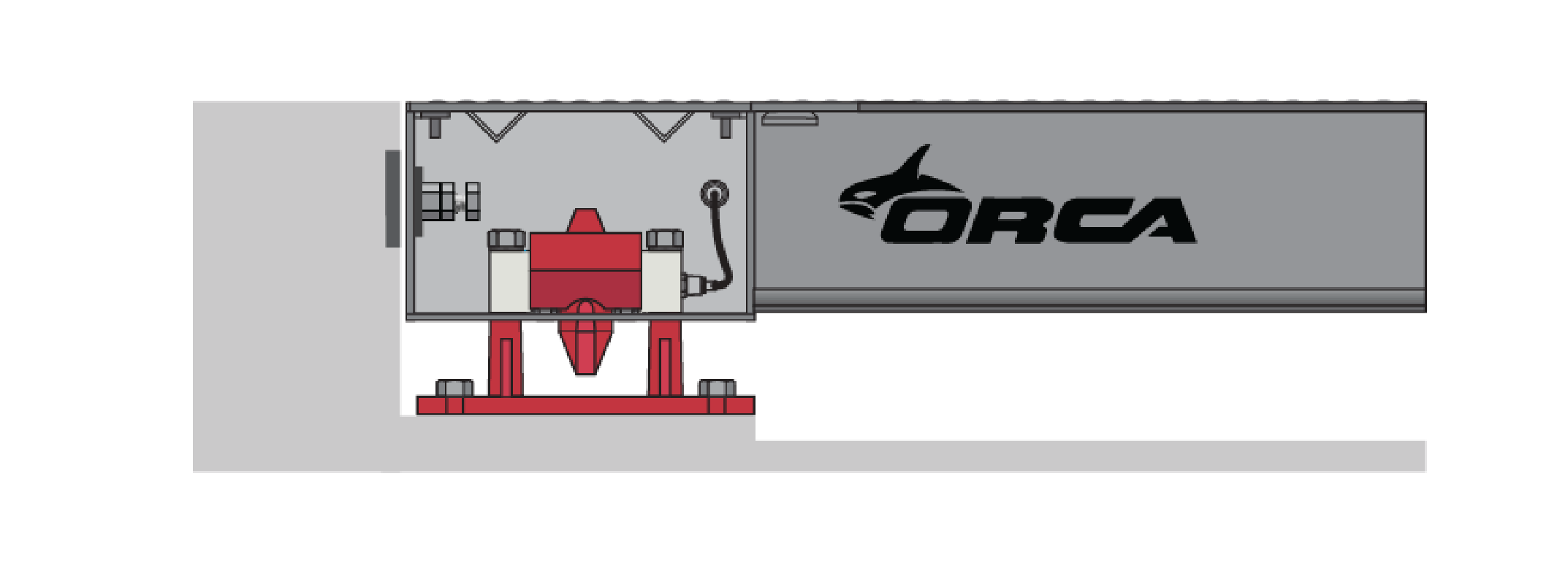

- U-Channel construction, used in ANYLOAD truck scales, distributes axle loads across multiple closely spaced vertical webs. This structure forms a continuous, sealed deck that offers greater torsional rigidity, improved fatigue performance, and better long-term geometric stability. Pre-cambering further resists sagging and water pooling, maintaining deck flatness and calibration accuracy over extended service life.

While more complex to manufacture (requires a very large CNC hydraulic folding machine), U-channel construction achieves superior structural efficiency. The result is a scale that delivers high strength, stiffness, and reliability without unnecessary mass, ensuring sustained performance under heavy, repetitive loading conditions.

NOTE: As an added measure of reassurance for product longevity, ANYLOAD paints the insides of the U-channels as well.

Double-Ended Beam vs. Canister Load Cells

While load cells are often treated as interchangeable components, their mechanical design principle and how they integrate with the weighbridge directly affects scale performance and reliability.

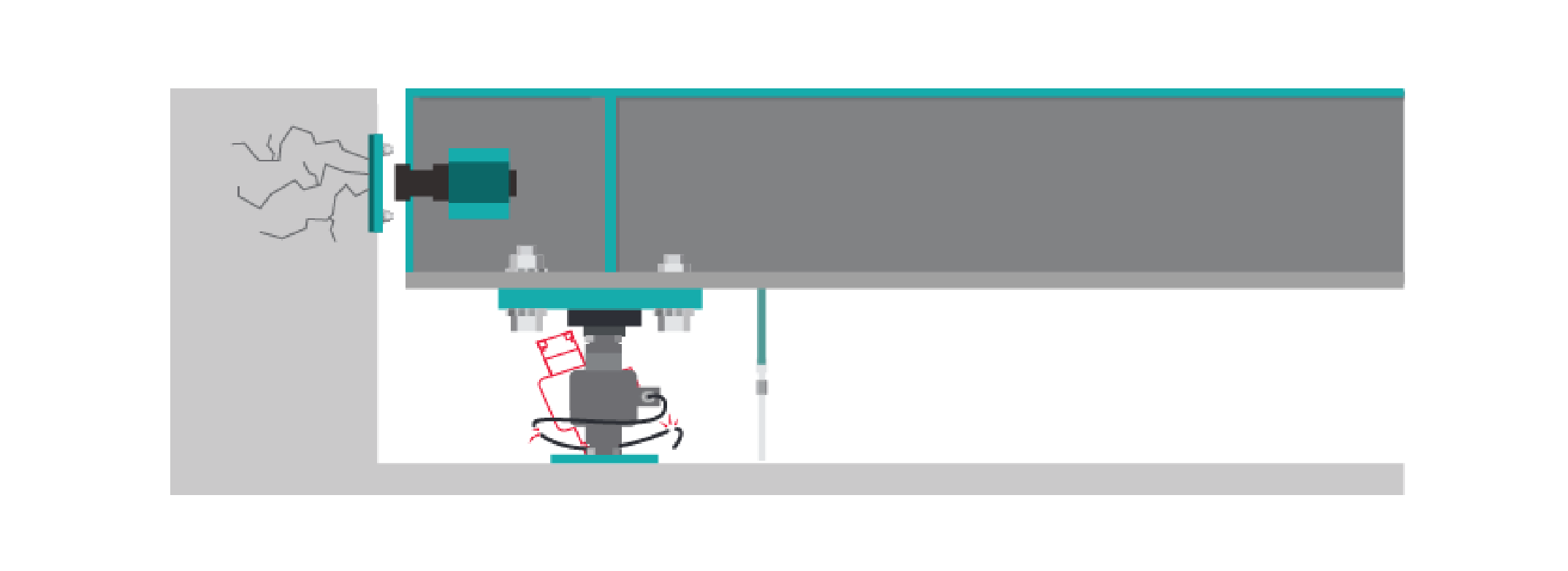

- Canister (rocker column) load cells use a single-point column resting on a curved bearing surface that allows the deck to rock into position under load. This self-centering action works well in controlled conditions but relies on additional hardware (check rods, bumper bolts, and mounting cups) to restrain lateral movement. Over time, the canister may rotate or tilt, placing stress on cabling and requiring periodic realignment or replacement. While this design offers a cost-effective solution and long field history, it typically involves more components and maintenance effort. However, this load cell design is more economical as it uses less steel and is easier to manufacture

- Double-ended shear beam load cells are supported at both ends with the load applied at the center through a self-aligning link or mount. This configuration directs the load vertically, improving force transfer and reducing side loading. Fewer moving parts mean greater long-term stability, easier installation, and less frequent adjustment. When integrated with modern single-link mounting systems, double-ended beams deliver higher reliability, reduced maintenance requirements, and better weighing consistency, particularly in high-throughput or heavy-duty applications.

Bolted vs. Bracket Connections

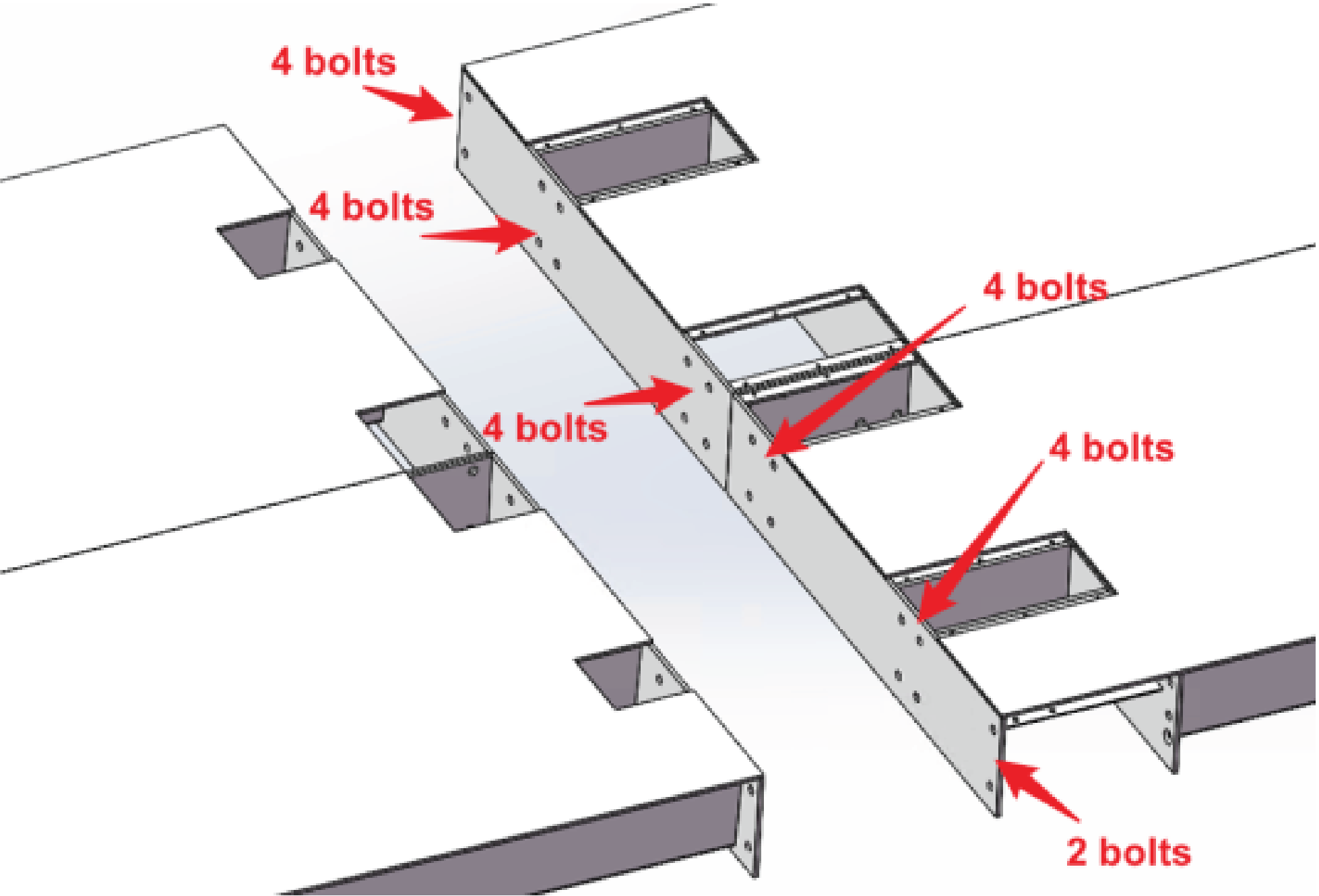

The way scale modules are connected affects not only installation speed but also long-term serviceability.

- Bolted connections are straightforward to manufacture and have been used for decades; however, their performance depends on precise alignment of bolt holes and consistent torque during assembly. In the field, rust, debris, and thermal expansion can complicate reinstallation, as misalignment between holes increases with use and exposure. Servicing or relocating a bolted scale often requires unfastening numerous bolts, adding both time and labour.

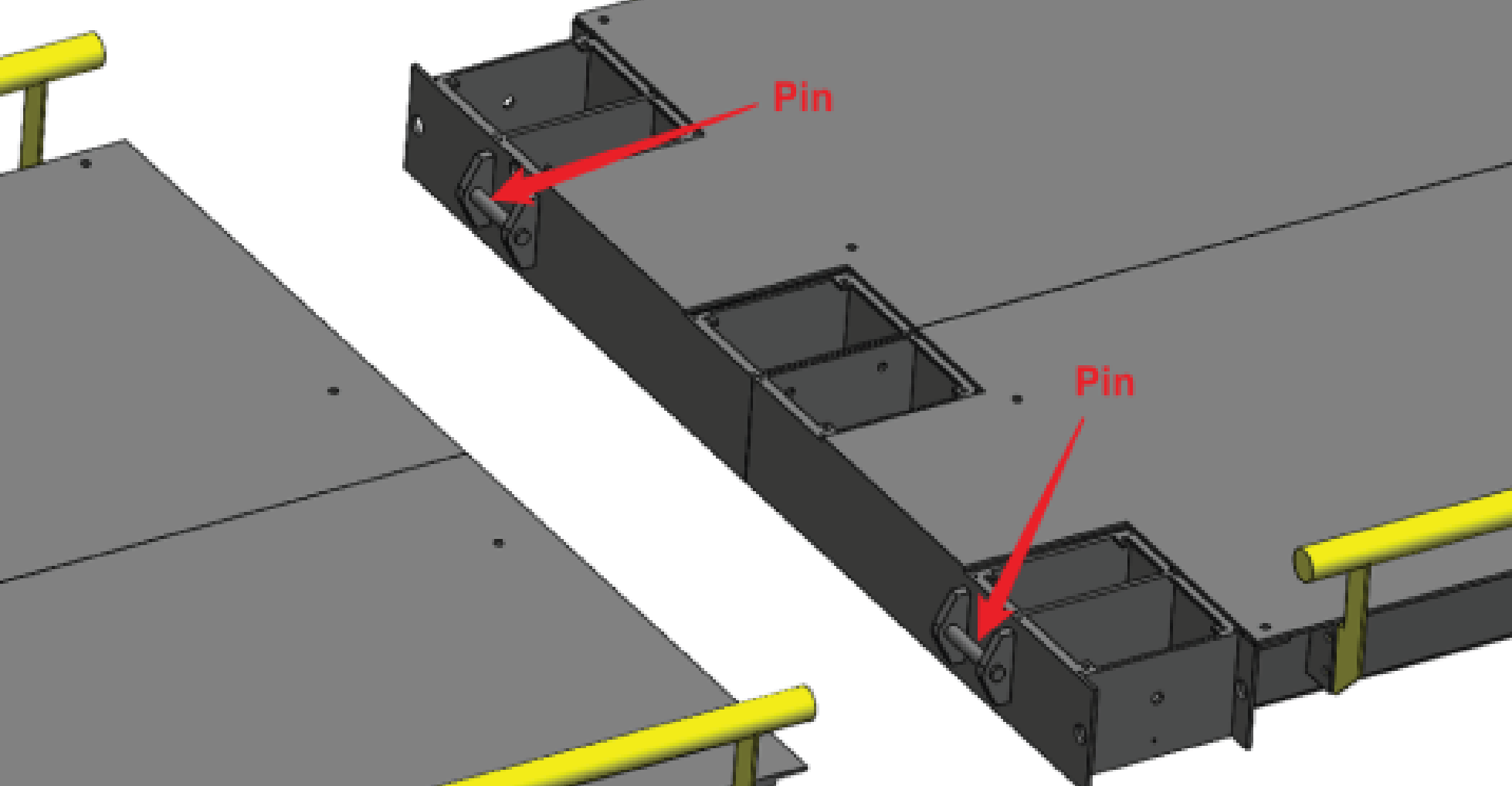

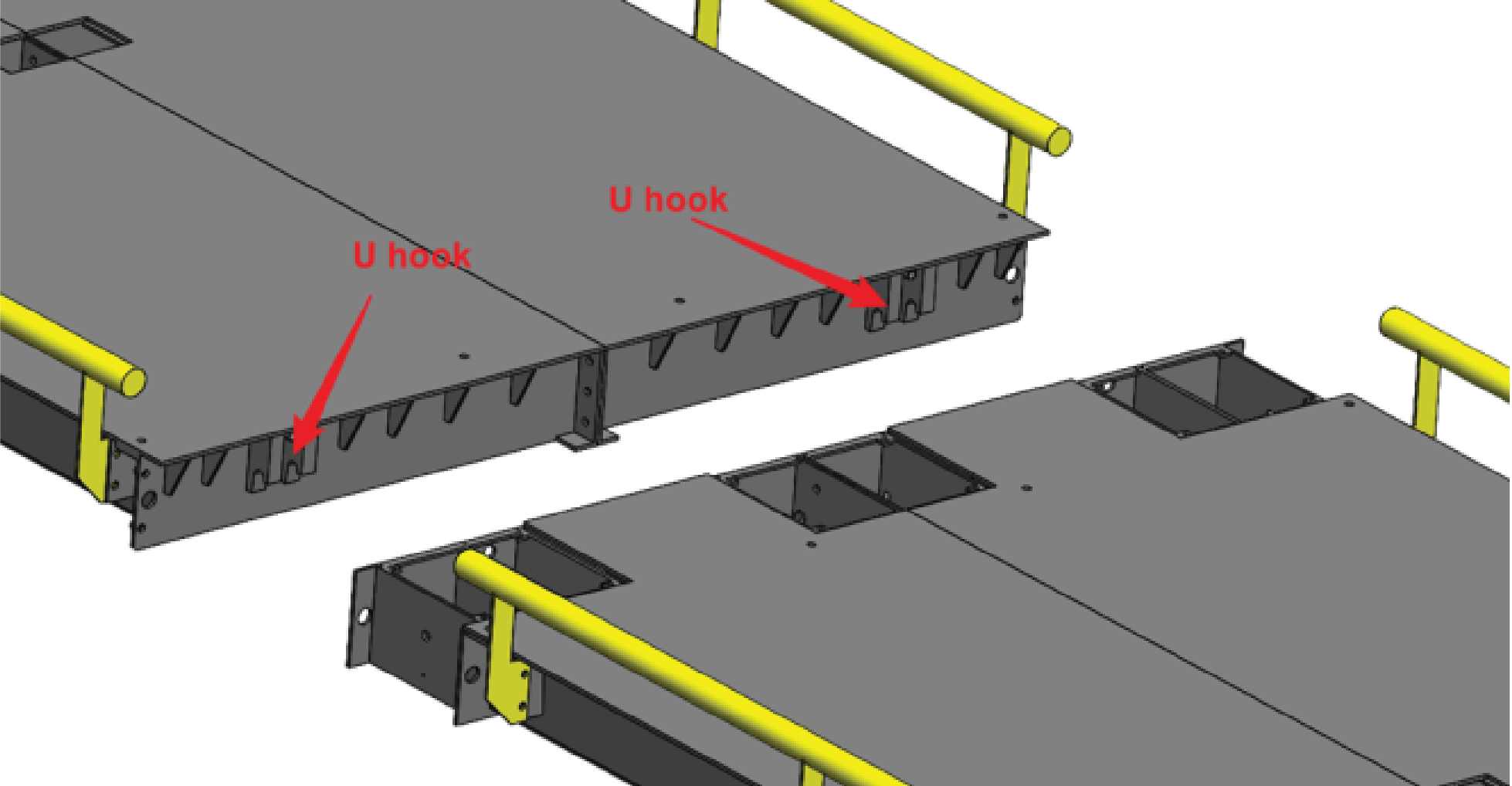

- ANYLOAD’s drop-in H-bracket connection system replaces bolting with a pin-and-bracket mechanism that effortlessly aligns adjoining scale sections. The design locks the modules securely while allowing natural thermal expansion and contraction of the structure. This approach simplifies installation, reduces hardware requirements, and makes future maintenance or relocation much more convenient.

Additional Design Elements

Several complementary design features further strengthen the structural integrity and longevity of ANYLOAD truck scales:

- Deck Thickness: Heavy treadplates, typically ⅜″ (10mm) or ½″ (12mm), improve wear resistance and structural rigidity, especially in abrasive or corrosive environments such as mining and aggregate operations.

- Cross-Bracing: Welded horizontal bracing across the deck width enhances torsional rigidity and minimizes lateral flexing when vehicles enter off-center, maintaining weighing accuracy and scale geometry.

- Cambering: A controlled, upward convex curvature is built into each deck section to counteract deflection under load. This pre-camber ensures the platform settles flat when loaded, improving long-term fatigue resistance and allowing water to drain naturally from the surface.

Scale Fabrication

A good design is important, yet fabrication often has a more immediate impact on quality. While sound engineering determines how a scale should perform, the quality of fabrication dictates whether that performance is achieved in the field. In practice, a well-built scale based on an ordinary design often outlasts a poorly fabricated one based on advanced engineering. Every stage, from cutting and welding to finishing, directly affects structural integrity, corrosion resistance, and long-term reliability.

- Steel Cutting: Modern CNC laser cutting systems produce components with tight tolerances and clean edges, ensuring consistent fit and alignment throughout assembly. This improves the accuracy of weld joints, reduces stress concentrations, and enhances repeatability across production runs. By contrast, manual or torch cutting introduces uneven edges that can distort during welding, weakening the structure and compromising alignment.

- Welding: Welding quality determines how forces are transmitted through the scale frame. Continuous welding provides uninterrupted load paths, preventing the small flex points that form at intermittent or spot welds. Continuous seams resist fatigue cracking, moisture ingress, and corrosion.

The use of robotic welding systems further improves uniformity and depth of penetration, ensuring each weld is consistent in strength and finish. Automated welding minimizes human variation and produces stronger, cleaner joints that maintain scale geometry and long-term rigidity. - Paint: The paint system on a truck scale, aside from cosmetic appearance, is also the primary corrosion barrier protecting the structure from years of environmental exposure. Proper surface preparation is essential for coating adhesion.The industry standard for this process is ISO 8501-1 SA 2.5, commonly referred to as “near-white metal blast cleaning.” At this grade, the surface is free from visible oil, rust, scale, and other contaminants, with only slight discoloration from shadows or streaks.The surface should exhibit a uniform, finely roughened texture suitable for mechanical bonding. Achieving SA 2.5 requires abrasive or bead blasting that removes all mill scale and weld residue while ensuring the steel is not over-polished, which would reduce paint grip.

ANYLOAD employs multi-nozzle bead blasting to remove weld slag, grease, and mill scale, leaving a uniformly roughened surface ideal for primer bonding. Without this step, even premium coatings can delaminate prematurely.

After cleaning, the steel should be coated as quickly as possible to prevent flash rusting. High-quality coating systems typically include:- Epoxy primer, providing strong adhesion and corrosion resistance.

- Topcoat, such as polyurethane or resin epoxy, offering UV and abrasion protection.

- Curing: The curing process is equally critical. Oven curing (baked finish) accelerates solvent evaporation and promotes chemical cross-linking, forming a denser, more durable film compared to air drying. Properly cured coatings resist chipping, peeling, and chemical attack, significantly extending service life in outdoor and corrosive environments.. ANYLOAD uses a dual-layer resin epoxy automotive-grade paint, combining an epoxy primer for adhesion and corrosion resistance with a high-durability topcoat for UV and abrasion protection. Each coat is oven-cured in a controlled environment rather than air-dried. Oven curing allows solvents to evaporate fully and cross-linking to complete, creating a denser, harder coating that resists chipping, peeling, and chemical degradation.

The curing process is equally critical. Oven curing (baked finish) accelerates solvent evaporation and promotes chemical cross-linking, forming a denser, more durable film compared to air drying. Properly cured coatings resist chipping, peeling, and chemical attack, significantly extending service life in outdoor and corrosive environments.. ANYLOAD uses a dual-layer resin epoxy automotive-grade paint, combining an epoxy primer for adhesion and corrosion resistance with a high-durability topcoat for UV and abrasion protection. Each coat is oven-cured in a controlled environment rather than air-dried. Oven curing allows solvents to evaporate fully and cross-linking to complete, creating a denser, harder coating that resists chipping, peeling, and chemical degradation.

Evaluating the Quality and Value of a Weighbridge

Not all truck scales are built alike, even when they appear similar on paper. Manufacturing standards, fabrication methods, and material quality vary widely between producers, and these differences have lasting implications for accuracy, reliability, and lifecycle cost. When evaluating a scale or comparing bids, understanding how it is built is as important as what it costs.

Key Considerations When Assessing a Truck Scale

- Structural Design: Review whether the scale uses I-beam or orthotropic U-channel construction. U-channel designs distribute axle loads more evenly and reduce long-term fatigue, while I-beams may be simpler to fabricate but concentrate stress in fewer members.

- Fabrication Quality: Look for continuous welds rather than intermittent or spot welds, which can weaken over time. Robotic or precision welding ensures deep, consistent penetration and improved structural integrity.

- Surface Preparation and Coating: Verify that the steel is bead blasted to SA 2.5 (ISO 8501-1) prior to painting as this ensures proper coating adhesion and corrosion protection. A dual-coat epoxy or polyurethane system, properly oven-cured, provides longer-lasting resistance to rust, UV, and abrasion.

- Connection Method: Determine whether the scale modules use bolted or bracketed (drop-in) connections. Bracketed systems allow faster installation, better thermal expansion tolerance, and easier future relocation, while bolted connections are simpler but more maintenance-intensive.

- Modularity and Precision: Modular scales that align accurately and connect seamlessly are a sign of tight manufacturing tolerances and precise CNC fabrication, even if you do not need modularity. Consistency between sections reflects production precision and overall build quality.

- Load Cell System: Evaluate whether the scale uses double-ended shear beam or rocker column canister load cells. Beam-type systems generally require fewer moving parts and less frequent realignment, while canisters are cost-effective but need more routine inspection and adjustment.

- Paint and Corrosion Protection: Ask about the paint specification and curing process. A baked resin epoxy or automotive-grade coating offers superior durability over air-dried enamel. Coating quality is one of the strongest indicators of long-term resistance to corrosion and environmental wear.

Understanding Price Differences

A truck scale’s price reflects not just steel and electronics, but the engineering excellence and manufacturing control behind it. Scales built in automated facilities with CNC fabrication, robotic welding, and standardized coating systems will naturally command a higher initial cost than those built in low-volume workshops. However, the resulting benefits, including faster installation, reliable uptime, lower maintenance frequency, and longer service life, typically offset the difference many times over.

For engineers, bid managers, and purchasing teams, assessing these underlying details is essential. Experienced buyers understand that a well-built scale is not simply a commodity purchase but is a long-term investment in accuracy, safety, and operational continuity.

Learn More About Truck Scales

Truck scales perform a simple function of being a platform scale used to determine vehicle weights. For operators however, as an essential component of many operations and as a major investment, understanding how they work, how to select the best product, and how to use and maintain it will help reduce risks and costs.

Design & Fabrication:

Learn how the structural design, materials used, and fabrication technology all differentiate truck scale designs and manufacturers.

Operation:

Learn what happens during a scale installation and calibration as well as how site operators can maintain a scale to minimize downtime and repair costs. (For System Integrators)

Selection Guide:

Choose the right truck scale for your needs by learning how to navigate the many choices on offer as well as which specifications and details to be mindful of.