Guide to Truck Scale – Introduction

Last Updated On October 28, - 15 minutes de lecture

Truck scales are foundational to the safe, efficient, and compliant movement of goods across virtually every sector of the economy. Whether in logistics hubs, mining operations, agricultural terminals, or industrial processing plants, these systems serve a singular and vital purpose: accurately determining vehicle weight. This simple function underpins regulatory compliance, transaction integrity, infrastructure protection, and operational efficiency.

Introduction: What is a Truck Scale?

A truck scale, also referred to as a vehicle scale or weighbridge, is a large, heavy-duty platform designed to measure the total weight of a vehicle and its cargo. Constructed from structural steel and sometimes concrete, truck scales operate using precision load cells strategically mounted beneath the deck. These load cells detect mechanical force and convert it into accurate electronic weight measurements, enabling precise and repeatable readings across a range of applications.

Typical full-length truck scales range from 60 to 120 feet (18 to 36 meters) in length and 10 to 12 feet (3 to 4 meters) in width, with gross capacity ratings of up to 280,000 lbs (130 metric tons).

Applications :

Truck scales are widely deployed across industries where vehicle weight plays a critical role in compliance, billing, inventory tracking, or safety enforcement. Weighbridges serve as essential infrastructure in both public and private sectors.

Highways and Enforcement Weigh Stations

Governments and transportation authorities operate permanent and mobile weigh stations to enforce road weight regulations. These legal-for-trade truck scales help prevent overloading, reduce road damage, and ensure that commercial carriers comply with axle and gross vehicle weight limits.

Concrete, Asphalt, and Bulk Batching Plants

Truck scales are a core part of daily operations at ready-mix concrete, asphalt, and aggregate processing plants. Materials are weighed both in and out to ensure batch accuracy, verify deliveries, and manage raw inventory levels. Precision and reliability are crucial, particularly in high-throughput environments where frequent scale usage occurs under heavy loads and abrasive conditions.

Logistics and Freight Terminals

At distribution centers, cross-docks, and intermodal facilities, truck scales are used to verify load compliance before shipping and to reconcile weights for billing or documentation. Accurate weight data reduces freight disputes and helps ensure that trailers are loaded evenly and safely, especially for over-the-road and international shipping operations.

Waste Management and Recycling

Waste transfer stations and recycling yards use truck scales to measure inbound and outbound material volumes for billing, landfill fee calculation, and regulatory reporting. These environments are often harsh and debris-filled, typically requiring rugged scale platforms and corrosion-resistant components.

Agriculture and Grain Handling

Truck scales are widely used at grain elevators, feed mills, and farms to weigh bulk commodities such as corn, soybeans, wheat, or livestock feed. Farmers and cooperatives rely on truck scales to measure yield, determine payments, and monitor harvest volumes. Seasonal use, mobile subframe setups, and integrated grain dump systems are common features in agricultural applications.

Type of Truck Scales

Truck scales come in a variety of configurations to suit different weighing needs, site conditions, and regulatory requirements. The right type of scale depends on factors such as space availability, required accuracy, traffic volume, mobility, and whether the application is legal-for-trade.

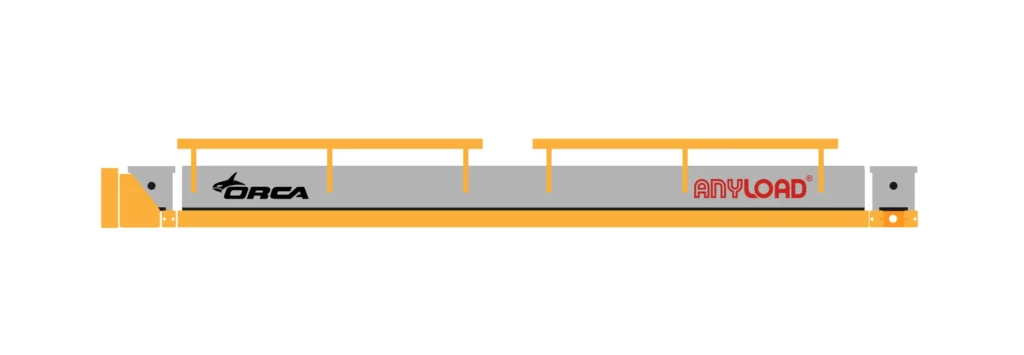

Full-Length Truck Scales

The vast majority of truck scales are full-length truck scales. They are designed to weigh a vehicle (including tractor and trailer) in a single pass. These scales typically range from 60 to 120 feet in length and are used in high-throughput operations such as freight terminals, batching plants, and agricultural receiving sites. They are often installed on permanent foundations (pit, slab, or pier) and are certified for legal-for-trade use. Full-length scales provide total gross weight and, when paired with software or indicators, can calculate net and tare values as well.

NOTE: ORCA and OTTER-series permanent steel deck truck scales represent this design.

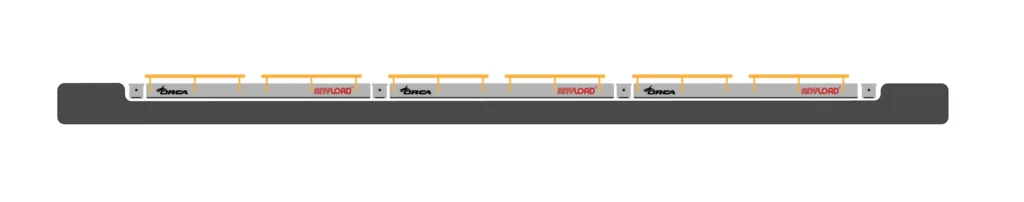

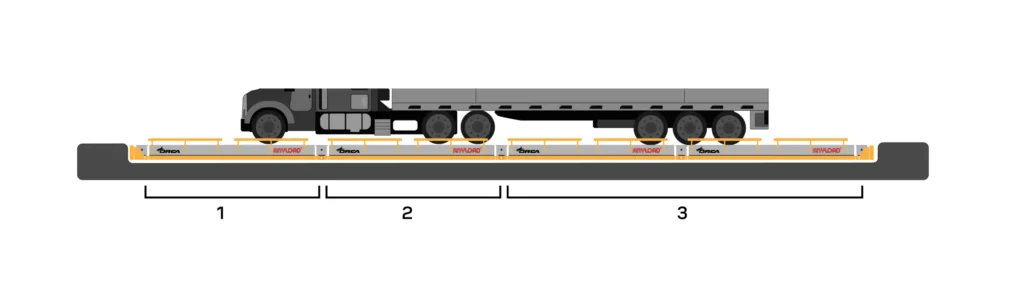

Multi-Axle Truck Scales

Multi-axle scales weigh the entire vehicle while also capturing individual axle or axle group weights. This is particularly important in regions with strict axle load regulations. Multi-axle systems are typically composed of variable length weighbridge sections and synchronized through an integrated indicator system. These are common at enforcement stations, fleet yards, and bulk haulers where weight distribution is critical.

NOTE: ORCA and OTTER-series truck scales can be configured into multi-axle scale systems.

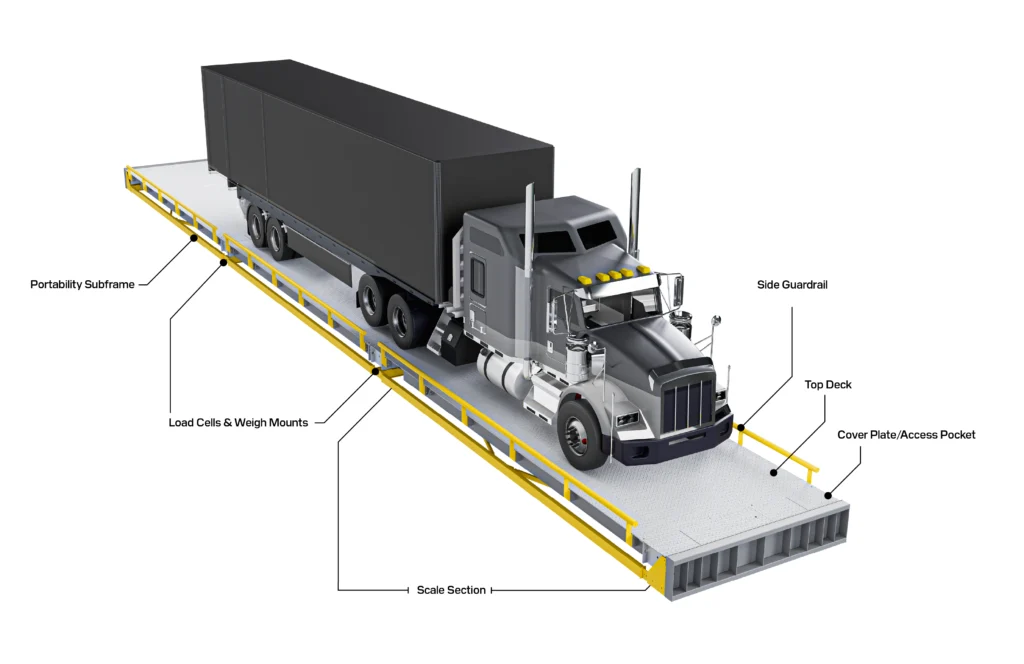

Portable Truck Scales

Portable truck scales are modular systems designed for temporary or mobile installations. Mounted on steel subframes which serve as a mobile foundation for the weighbridge, these steel deck scales are ideal for construction projects, seasonal agricultural operations, or remote job sites as they’re designed for rapid deployment and disassembly. Portable scales maintain high accuracy comparable to a permanent scale and can be certified for legal-for-trade use, provided the foundation and levelling are properly managed. They offer flexibility without compromising performance.

NOTE: Portability subframes can be paired with all standard ORCA and OTTER-series truck scales.

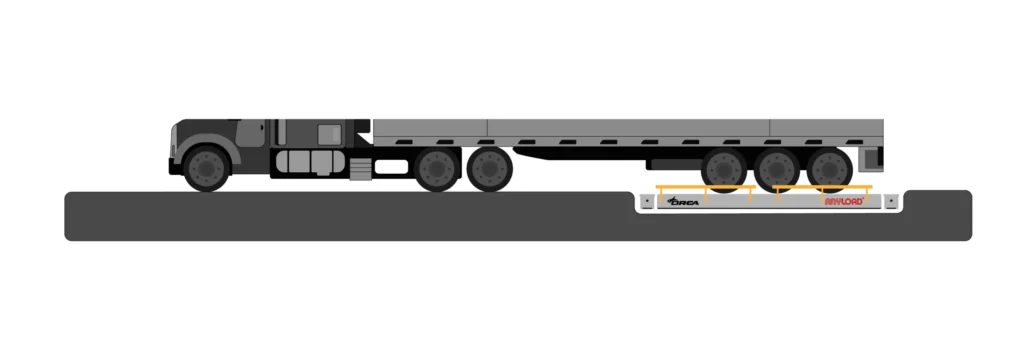

Single-Axle Scales and Axle Group Scales

These scales measure one axle or axle group at a time, with the vehicle either driving across slowly or stopping briefly on each segment. Total weight is calculated by summing the axle readings. Most are used for internal checks and compliance screening, and are not typically trade approved. Single-axle scales are typically more compact and cost-effective than full-length systems, making them attractive for lower-volume or space-constrained sites. These scales are generally not eligible to be legal-for-trade approved.

NOTE: ORCA and OTTER-series truck scales are also available in shorter, axle scale configurations.

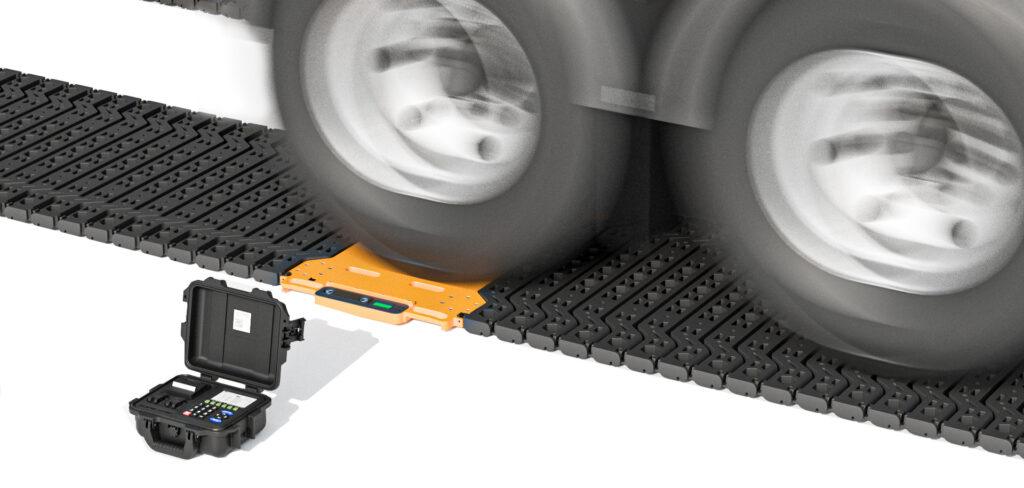

Tampons de pesée d'essieu

While technically separate from truck scales, axle weigh pads are a portable form of vehicle weighing. These lightweight, low-profile pads are placed under each axle and are typically used for compliance checks, weight balancing, and preliminary screenings, not for legal-for-trade purposes. They are quick to set up and move but offer low accuracy and are more sensitive to surface conditions and vehicle motion. Despite this, they remain a valuable tool in fleet operations, enforcement programs, and mobile inspection setups.

NOTE: ANYLOAD’s AXA-series portable axle weigh pad scales offer best-in-class accuracy, portability, durability, and battery life.

Weigh-In-Motion (WIM) Scales

Weigh-in-motion systems allow vehicles to be weighed while in motion, without stopping. These systems are ideal for pre-screening trucks at highway weigh stations, ports, and logistics gates where stopping every vehicle would cause congestion. While not typically used for legal-for-trade transactions, advanced WIM systems can be certified in some regions with proper calibration and traffic control measures. Their efficiencies make them increasingly popular for enforcement and fleet screening, though their accuracy remains inferior by an order of magnitude compared to conventional weighbridges due to the dynamic forces involved. Careful vehicle speed enforcement and frequent recalibrations are also required to maintain meaningful accuracy.

NOTE: ANYLOAD’s AXA-8 axle weigh pad scales have weigh-in-motion capability when used in conjunction with rubber extension pads and the AN560 wireless indicator.

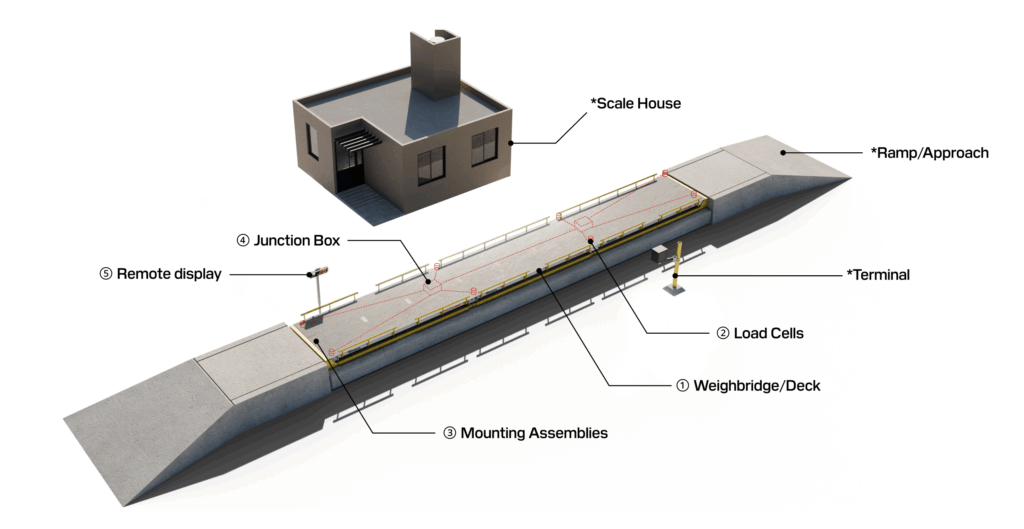

Overview of a Truck Scale System

NOTE: ORCA and OTTER-series permanent steel deck truck scales represent this design.

Multi-Axle Truck Scales

① Weighbridge / Deck

The main platform that supports the truck. Made of steel or concrete, often in modular sections. Available in treadplate steel or poured concrete finishes depending on site needs and environment.

② Load Cells

These are the core measuring devices that detect force and convert it into an electrical signal. Located at strategic support points beneath the deck. Load cell performance directly determines scale accuracy.

③ Mounting Assemblies

Connect the weighbridge to the load cells. High-quality mounts reduce side-load effects and allow for natural expansion, contraction, and shock absorption.

④ Junction Box

Combines output from multiple load cells into a single, calibrated signal. Located within the frame or protected housing, and used for trimming and diagnostics.

⑤ Indicator / Terminal

Displays real-time weight and processes transactions. Often located in a scale house or remote kiosk. May include printers, memory storage, and data outputs.

*Peripheral Equipment

Includes:

- Ramps: For raised installations.

- Scale House: To house onsite scale attendant, weighing equipment, and systems.

- Guardrails: Mounted On the deck or foundation to prevent trucks from veering off.

- Remote Displays: Weight readout for drivers & operators.

- Traffic Lights: To guide entry/exit in high-flow areas.

- Unattended Terminals: For driver self-service operations.

- Manhole: Access for accessing pit foundations and servicing the scale.

- Grain Dump / Unloading Port: Allows trucks to unload directly through the scale deck while remaining positioned for weighing (ideal for grain elevators and feed facilities).

Learn More About Truck Scales

Truck scales perform a simple function of being a platform scale used to determine vehicle weights. For operators however, as an essential component of many operations and as a major investment, understanding how they work, how to select the best product, and how to use and maintain it will help reduce risks and costs.

Design & Fabrication:

Learn how the structural design, materials used, and fabrication technology all differentiate truck scale designs and manufacturers.

Operation:

Learn what happens during a scale installation and calibration as well as how site operators can maintain a scale to minimize downtime and repair costs. (For System Integrators)

Selection Guide:

Choose the right truck scale for your needs by learning how to navigate the many choices on offer as well as which specifications and details to be mindful of.